Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Ingersoll Rand Refrigerated Dryer D212NC-A16-2

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

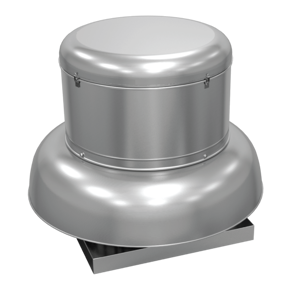

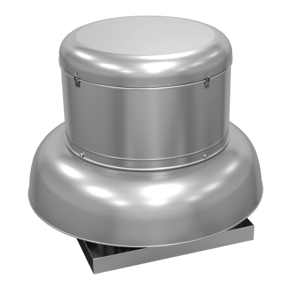

Ingersoll Rand Refrigerated Dryer D212NC-A16-2

Create an account to install this asset package.

Maintenance Plans for Ingersoll Rand Refrigerated Dryer Model D212NC-A16-2

Integrate maintenance plans directly into your work orders in MaintainX.

Condenser Fins Maintenance

Safety Precautions

Only qualified personnel are permitted to adjust, perform maintenance or repair this air dryer.

Read all instructions completely before operating unit.

Pull main electrical disconnect switch and disconnect any separate control lines, if used, before attempting to work or perform maintenance on the unit.

Do not attempt to service any part while machine is in an operational mode.

Refrigerant Condenser

Inspect condenser fins

Clean condenser fins

Is there excessive dirt, dust or debris?

1 Monthly Drain Check

Safety Precautions

Only qualified personnel performing maintenance or repair?

All instructions read before operating unit?

Main electrical disconnect switch pulled and any separate control lines disconnected before work or maintenance?

No service attempted while machine is in operational mode?

Condensate Discharge System

Drain operation checked on a monthly basis?

Sign off on the monthly drain check

1 Daily Refrigerated Dryer Maintenance

Safety Precautions

Only qualified personnel shall be permitted to adjust, perform maintenance or repair this air dryer.

Read all instructions completely before operating unit.

Pull main electrical disconnect switch and disconnect any separate control lines, if used, before attempting to work or perform maintenance on the unit.

Do not attempt to service any part while machine is in an operational mode.

Do not attempt to remove any parts without first relieving the entire air system of pressure.

Do not attempt to remove any part of the refrigeration system without removing and containing refrigerant in accordance with the EPA and local regulations.

Do not operate the dryer at pressures in excess of its rating.

Do not operate the dryer without guards, shields and screen in place.

Refrigerated Dryer Maintenance

Safety Precautions

Only qualified personnel performing maintenance?

All instructions read before operating unit?

Main electrical disconnect switch pulled and any separate control lines disconnected before work?

No service attempted while machine is operational?

Introduction

Ingersoll Rand Nirvana Cycling dryers require little maintenance. These dryers utilize hermetically sealed compressors which do not require any lubrication.

Ingersoll Rand recommends component inspection and service at regular intervals to obtain maximum performance from your dryer.

Component inspection performed?

Drain Cleaning

Safety Precautions

Only qualified personnel performing the task?

All instructions read before operating unit?

Main electrical disconnect switch and any separate control lines disconnected before work?

No attempt to service any part while machine is operational?

Condensate Discharge System

Drain removed and cleaned periodically?

Drain isolation valve manually closed during cleaning?

Warning

Parts for Ingersoll Rand Refrigerated Dryer D212NC-A16-2

Access the parts list for your equipment in MaintainX.

Exchanger Assy

23141666

Evaporator Assy

23141658

Glycol Pump

23141245

Timed Sol. Drain

23141260

Compressor

23141120

Exchanger Assy

23141666

Evaporator Assy

23141658

Glycol Pump

23141245

Timed Sol. Drain

23141260

Compressor

23141120

Exchanger Assy

23141666

Evaporator Assy

23141658

Glycol Pump

23141245

Timed Sol. Drain

23141260

Compressor

23141120

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX