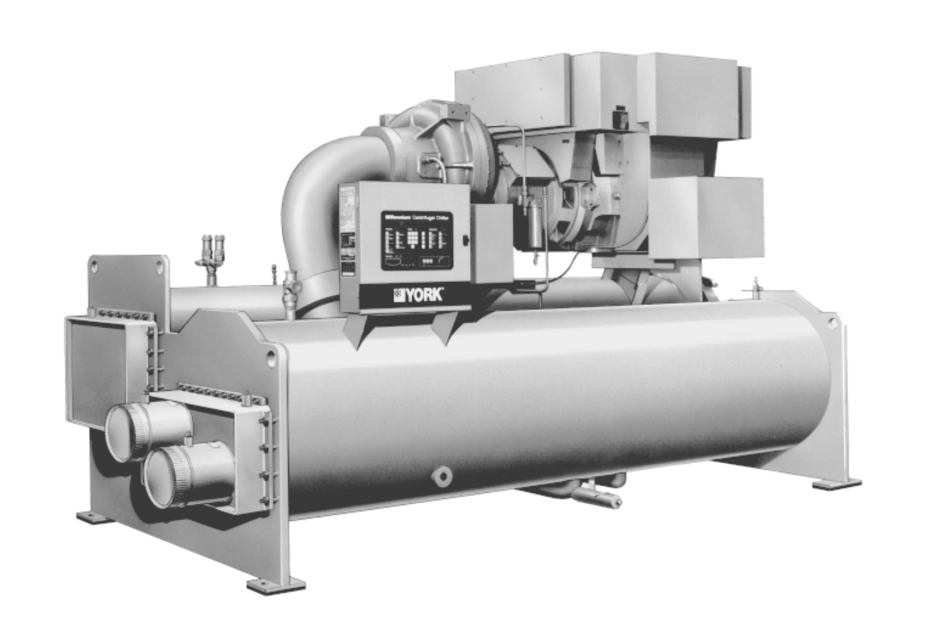

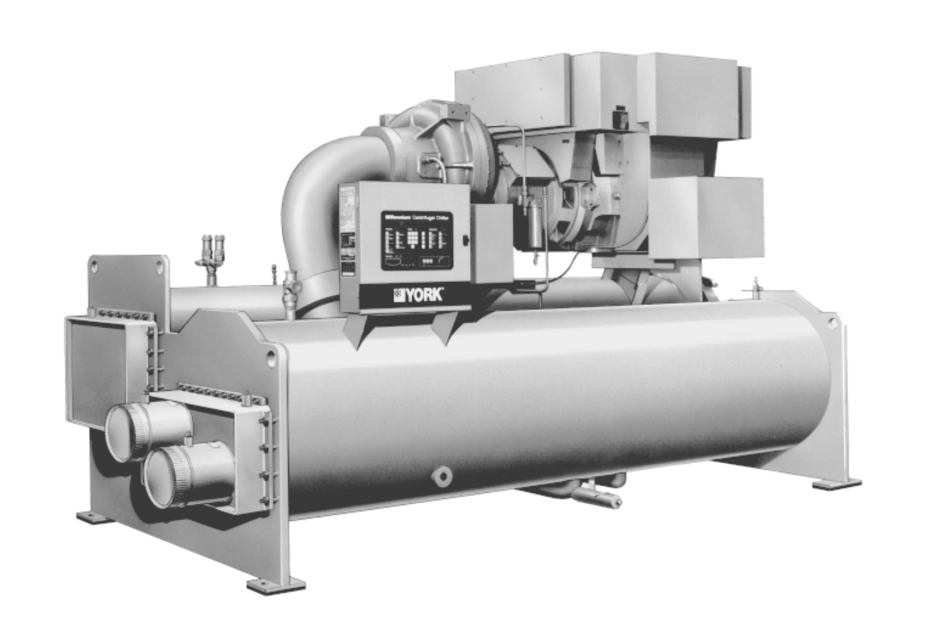

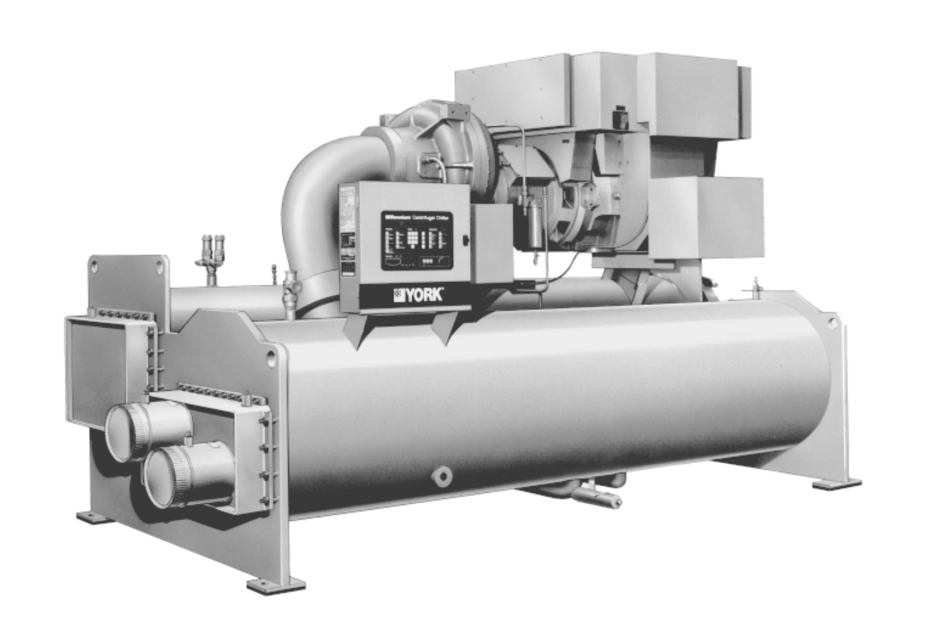

The York Centrifugal Liquid Chillers Millennium series offers high-efficiency cooling solutions for industrial applications. Known for their reliability and advanced technology, these chillers are designed to optimize performance while minimizing energy consumption. Ideal for large facilities, they ensure consistent temperature control and operational efficiency.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for York CENTRIFUGAL LIQUID CHILLERS MILENNIUM

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

York CENTRIFUGAL LIQUID CHILLERS MILENNIUM

Create an account to install this asset package.

Maintenance Plans for York CENTRIFUGAL LIQUID CHILLERS Model MILENNIUM

Integrate maintenance plans directly into your work orders in MaintainX.

Weekly Check

- Check the refrigerant charge.;

Monthly Maintenance

1. Change and inspect compressor oil filter element.

2. Oil return system.

a. Change dehydrator.

b. Check nozzle of eductor for foreign particles.

3. Check controls and safety cutouts.;

Yearly Maintenance

1. Drain and replace the oil in the compressor oil sump. (See Charging The Unit With Oil, page 44.)

2. Cooler and Condenser.

a. Inspect and clean water strainers.

b. Inspect and clean tubes as required.

c. Inspect end sheets.

3. Compressor Drive Motor (See motor manufacturers maintenance and service instruction supplied with unit)

a. Clean air passages and windings per manufacturers instructions.

b. Meg motor windings See Fig. 23 for details.

c. Lubricate ball bearings.

Monthly Inspection

- Perform chemical analysis of oil.;

Daily Maintenance

1. Check MicroComputer Control Center displays.

2. If the compressor is in operation, check the bearing oil pressure by pressing OIL PRESSURE key to read the display on the Control Center. Also check the oil level in the oil reservoir. Operating oil level should be between the upper and lower sight glasses. Drain or add oil if necessary.

3. Check entering and leaving condenser water pressure and temperatures for comparison with job design conditions. Condenser water temperatures can be checked by pressing CONDENSER LIQUID TEMPERATURES display key.

4. Check the entering and leaving chilled liquid temperatures and evaporator pressure for comparison with job design conditions. This can be accomplished by pressing the CHILLED LIQUID TEMPS key and the REFRIGERANT PRESSURES key.

5. Check the condenser saturation temperature (based upon condenser pressure sensed by the condenser transducer). Press the DISPLAY DATA key. This key may be depressed repeatedly after depressing the DISPLAY HOLD key to display three different parameters.

6. Check the compressor discharge temperature. Press DATA DISPLAY key. During normal operation discharge temperature should not exceed 220°F.

7. Check for any signs of dirty or fouled condenser tubes. (The temperature difference between water leaving condenser and saturated condensing temperature should not exceed the difference recorded for a new unit by more than 4°F).

8. Press the STATUS key whenever the display indicates so. This allows any warning messages to be displayed.;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX