Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

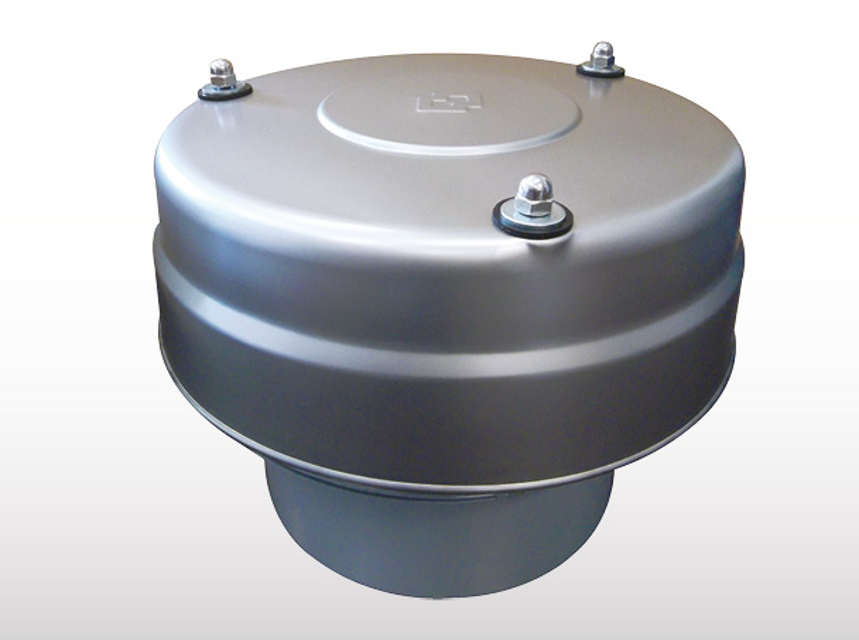

Manual for WAM Group Spring-Loaded Pressure Relief Valves VCP 375

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

WAM Group Spring-Loaded Pressure Relief Valves VCP 375

Create an account to install this asset package.

Maintenance Plans for WAM Group Spring-Loaded Pressure Relief Valves Model VCP 375

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Spring-Loaded Pressure Relief Valve Inspection

Warning: Failure to follow the instructions strictly can cause problems and invalidate the warranty on the machines supplied.

PERIODIC INSPECTIONS REQUIRED

Before any kind of operation, set the machine in safety status.

Is the machine in safety status?

For working on the valve on the silo first clean the inside of the valve and then the surrounding area, taking care to avoid throwing up dust.

Is the inside of the valve and the surrounding area clean?

The following indications must be strictly followed:

Carry out complete revision of the valve (see disassembly/reassembly) with replacement of the membranes and thorough cleaning of all the elements after revision.

Was a complete revision of the valve carried out with replacement of the membranes and thorough cleaning of all the elements after revision?

2 Yearly Spring-Loaded Pressure Relief Valve Inspection

Warning: Failure to follow the instructions strictly can cause problems and invalidate the warranty on the machines supplied.

PERIODIC INSPECTIONS REQUIRED

Before any kind of operation, set the machine in safety status.

Is the machine in safety status?

For working on the valve on the silo first clean the inside of the valve and then the surrounding area, taking care to avoid throwing up dust.

Is the inside of the valve and the surrounding area clean?

The following indications must be strictly followed:

Have the springs been replaced?

Have the bellows been replaced?

1 Weekly Spring-Loaded Pressure Relief Valve Inspection

Failure to follow the instructions strictly can cause problems and invalidate the warranty on the machines supplied.

PERIODIC INSPECTIONS REQUIRED

Before any kind of operation, set the machine in safety status.

For working on the valve on the silo first clean the inside of the valve and then the surrounding area, taking care to avoid throwing up dust.

The following indications must be strictly followed:

- Check for dust in the area around the valve, remove the cover to clean encrustation that may be present, check to make sure the two membranes move freely.

- Check to make sure the outlet is clear of material residues: if necessary, clean to remove all obstruction in the material passage.;

1 Monthlly Spring-Loaded Pressure Relief Valve Inspection

Warning: Failure to follow the instructions strictly can cause problems and invalidate the warranty on the machines supplied.

PERIODIC INSPECTIONS REQUIRED

Before any kind of operation, set the machine in safety status.

Is the machine in safety status?

For working on the valve on the silo first clean the inside of the valve and then the surrounding area, taking care to avoid throwing up dust.

Is the inside of the valve and the surrounding area clean?

The following indications must be strictly followed:

Check the gasket for wear, especially with granular products which can be the cause for rapid wear.

If there are any issues, describe them here.

Spring-Loaded Pressure Relief Valve Cleaning

Warning: Set the machine in safety status before carrying out any operation.

Machine set in safety status?

Warning: Avoid spreading dust in the surrounding area while cleaning.

Dust contained during cleaning?

Select the type of cleaning materials used

Warning: If handling food products, use non-toxic detergents.

Non-toxic detergents used for food products?

Frequency of cleaning operations

Warning: In case of harmful, toxic products, convey waste into a closed tank and dispose off in accordance with product safety chart.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX