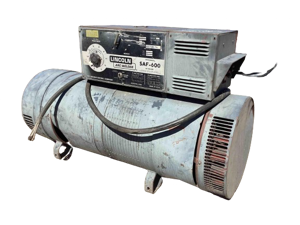

The Lincoln Electric COOLARC 55 is a high-performance aluminium water cooler designed for efficient cooling in industrial applications. This robust asset ensures optimal temperature control, enhancing productivity and equipment longevity. Regular maintenance is essential for peak performance and reliability.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Lincoln Electric Lincoln Electric Aluminium Water Cooler COOLARC 55 COOLARC 55

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Lincoln Electric Aluminium Water Cooler COOLARC 55 COOLARC 55

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Lincoln Electric Aluminium Water Cooler COOLARC 55 Model COOLARC 55

Integrate maintenance plans directly into your work orders in MaintainX.

Heat Exchanger Maintenance

- Clean the heat exchanger periodically using a vacuum hose or a low-pressure air line. Avoid placing the unit near a flux hopper or a flux waste container

- A clean heat exchanger offers better cooling performance and longer product life. In extremely dirty environments, it may be necessary to remove the heat exchanger completely from the cooler and clean the fins with soap and water. Use care to avoid damaging the fins;

Pump Maintenance

- Drain the coolant reservoir and all coolant lines. Dispose of the coolant properly as specified above

- Hold the pump head firmly to apply a counter-torque when loosing the strainer's 7/8" acorn nut located on the bottom. Do not confuse with 3/4" acorn nut. Remove nut and slide inlet strainer down and out from the pump head

- Gently rinse the strainer under running water to thoroughly clean it

- Use a mirror to inspect the inside of the pump for contamination. Carefully remove hardened debris with a dental pick if necessary, without scratching the inside of the pump

- Reinstall the strainer and 7/8 acorn nut, tightening with 75+/-15 in-lbs. of torque. Wipe dry all area wetted with coolant. Dispose of coolant soaked towels properly as specified above;

Resevoir Coolant Level Check

- Remove the reservoir fill cap and check the coolant level

- The reservoir is full when the coolant level is just below the reservoir fill opening

- Keep the reservoir full, especially after disconnecting the water lines or changing the accessory being cooled;

Parts for Lincoln Electric Lincoln Electric Aluminium Water Cooler COOLARC 55 COOLARC 55

Access the parts list for your equipment in MaintainX.

Hose Clamp

9SS10888-35

Hose Clamp

9SS10888-35

Front Mounting Bracket Asbly

9SS28458

Flex Tube

9ST10642-326

Lock Washer

9SE106A-27

Hose Clamp

9SS10888-35

Hose Clamp

9SS10888-35

Front Mounting Bracket Asbly

9SS28458

Flex Tube

9ST10642-326

Lock Washer

9SE106A-27

Hose Clamp

9SS10888-35

Hose Clamp

9SS10888-35

Front Mounting Bracket Asbly

9SS28458

Flex Tube

9ST10642-326

Lock Washer

9SE106A-27

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX