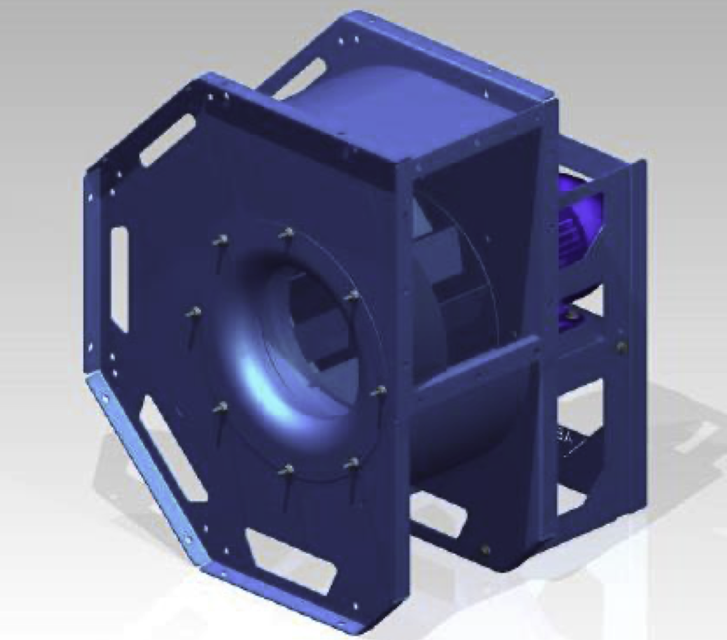

The Lincoln Electric Fixed Fan D350 is a robust industrial fan designed for efficient airflow and cooling in various applications. Known for its durability and performance, this model ensures optimal operation with regular maintenance and quality spare parts. Ideal for heavy-duty environments, the D350 is a reliable choice for industrial cooling solutions.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Fixed Fan D350

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Fixed Fan Model D350

Integrate maintenance plans directly into your work orders in MaintainX.

Bearing Replacement

- Expected lifetime of the bearings is 20 000 hrs. Replace them at this period

Fan Inspection

- Check that large quantities of dust are not deposited on the motor ventilation blades and that the air inlet openings are not blocked, as that could lead to motor overheating. Clean if necessary

- The fan rotor must be clean and regularly cleaned in order to avoid a drop in efficiency or wheel unbalance, which would damage the motor bearings

- Check the fastening of the bolts that hold the motor on its seat, the screws that fasten the impeller on the motor shaft (shaft end), and the nuts or screws holding the scroll on the seat

- Inspect the motor connections and the tightening of lugs (with the power off)

- Check the fastening of the stuffing boxes

- Check the motor condition according to the instructions of the motor manufacturer. For transmission fans, follow the bearing lubrication frequencies, check the alignment of bearings and belt tension

- Regularly check the vibrations from the fan and motor. If they are not normal, please contact the manufacturer.

Parts for Lincoln Electric Fixed Fan D350

Access the parts list for your equipment in MaintainX.

Air Inlet Grille

-

Motor

-

Fan Inlet Mouth

-

Fan Scroll

-

Fan Impeller

-

Air Inlet Grille

-

Motor

-

Fan Inlet Mouth

-

Fan Scroll

-

Fan Impeller

-

Air Inlet Grille

-

Motor

-

Fan Inlet Mouth

-

Fan Scroll

-

Fan Impeller

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX