The Eppendorf CO2 Incubator Shaker S41i is a versatile laboratory equipment designed for precise temperature and CO2 control, ideal for cell culture applications. This model combines incubation and shaking capabilities, ensuring optimal growth conditions for sensitive biological samples.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Eppendorf CO2 Incubator Shaker S41i

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Eppendorf CO2 Incubator Shaker S41i

Create an account to install this asset package.

Maintenance Plans for Eppendorf CO2 Incubator Shaker Model S41i

Integrate maintenance plans directly into your work orders in MaintainX.

Monthly Check

6.1.4 Monthly check

Auto-Zero the CO2 system at least once monthly to ensure that the CO2 level is correct.

We recommend monthly replacement of the water in the humidity trays. Clean the trays at the same time.

If required, you can take a sample of the gas inside the chamber using the CO2 sample port, and check it using a CO2 gas analyzer (see CO2 Sampling with Analyzer on p. 62).;

Daily Check

6.1.2 Daily checks

1. Check that the temperature and CO2 levels are reading within specification.

2. Check that gas supply lines have inline regulators, that they are properly installed and functioning.

3. Check the reserve pressure in the CO2 cylinder (normally 725 psi or 50 bar when full). The design of the incubator/shaker ensures very low consumption of CO2: during normal working conditions, a typical large cylinder should last approximately 12 months (frequent door openings will deplete the supply more rapidly).

If there is a significant drop at the cylinder pressure of 725 psi or 50 bar, it means that the cylinder is almost empty and should be replaced. Ensuring that there are no leaks at any of the connections will ensure a greater lifetime to the CO2 supply and will help avoid accidentally running out of CO2.

4. Check the ALARM and EVENT LOG screens for any alarms or events that may have occurred overnight.;

Weekly Check

6.1.3 Weekly checks

If you are using them for humidification, check the humidity trays and refill them as needed. Be careful not to exceed the maximum volume of 250 mL per pan. The use of warm water (~ 37.0 °C) will ensure a rapid return to optimum chamber conditions.;

Parts for Eppendorf CO2 Incubator Shaker S41i

Access the parts list for your equipment in MaintainX.

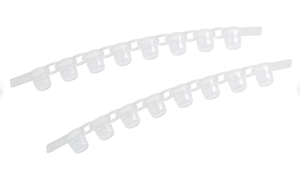

4 L Dedicated platform

M1334-9927

250 ml Dedicated platform

M1334-9922

2 L Dedicated platform

M1334-9925

2.8 L Dedicated platform

M1334-9926

125 ml Dedicated platform

M1334-9921

4 L Dedicated platform

M1334-9927

250 ml Dedicated platform

M1334-9922

2 L Dedicated platform

M1334-9925

2.8 L Dedicated platform

M1334-9926

125 ml Dedicated platform

M1334-9921

4 L Dedicated platform

M1334-9927

250 ml Dedicated platform

M1334-9922

2 L Dedicated platform

M1334-9925

2.8 L Dedicated platform

M1334-9926

125 ml Dedicated platform

M1334-9921

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX