The Eppendorf CO2 Backup System is a critical asset designed to maintain optimal conditions in laboratory environments. This reliable system ensures uninterrupted CO2 supply, safeguarding sensitive biological samples and experiments. Regular maintenance is essential for peak performance and longevity.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Eppendorf CO2 Backup System

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Eppendorf CO2 Backup System

Create an account to install this asset package.

Maintenance Plans for Eppendorf CO2 Backup Systemnull

Integrate maintenance plans directly into your work orders in MaintainX.

5 Yearly Replacement

The CO2 Back-up System runs on a rechargeable battery during a power failure.

Contact a qualified service engineer to replace the battery every 5 years or when the Low Battery Alarm sounds despite it being plugged into the mains.

Yearly Inspection

A qualified service engineer should inspect the CO2 transfer lines from the gas bottles to the solenoid valve annually.

Weekly Maintenance

- Clean with damp rag if necessary.

- Weigh CO2 supplies to see if they are full.

Monthly Inspection

All electrical cables should be checked every month. Failure to do so may result in failure of the device. If damage is found, do not attempt to repair by yourself.

1. Turn off CO 2 Back-up System and unplug the power cord from the mains.

2. Inspect the power cord, door switch cable, solenoid cable, and temperature sensor cable for cuts or other damage.

3. If damage is found, contact a qualifed service engineer to replace the damaged parts.

- Check for cuts or abrasions on all electrical wires.

- Inspect all hoses for cuts, chaffing, and squashing.

- Inspect hose connection to bottle and seal connection on the bottle. There should be no damage or corrosion.

- Inspect manifold plugs and seals. There should be no mechanical damage or corrosion.

- Inspect CO2 supply connection and solenoid valve connection. There should be no damage or corrosion.

Parts for Eppendorf CO2 Backup System

Access the parts list for your equipment in MaintainX.

Door Switch Magnet

K0400-0631

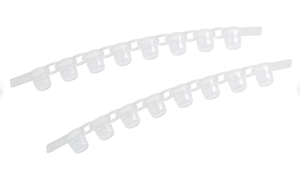

Transfer Line Assembly BS341 No.8

P0625-0201

Power Supply

P0625-0500

Battery - Control Unit

K0480-0220

PT100 Temperature Sensor Assembly

P0625-1410

Door Switch Magnet

K0400-0631

Transfer Line Assembly BS341 No.8

P0625-0201

Power Supply

P0625-0500

Battery - Control Unit

K0480-0220

PT100 Temperature Sensor Assembly

P0625-1410

Door Switch Magnet

K0400-0631

Transfer Line Assembly BS341 No.8

P0625-0201

Power Supply

P0625-0500

Battery - Control Unit

K0480-0220

PT100 Temperature Sensor Assembly

P0625-1410

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX