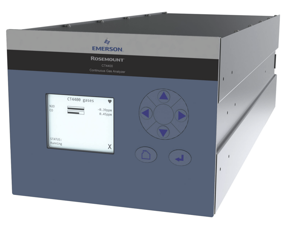

The Emerson Sample Handling System MicroCEM SHS is a sophisticated asset designed for efficient sample management in industrial applications. This system ensures precise handling and analysis, enhancing operational reliability and performance. With advanced features, the MicroCEM SHS is essential for maintaining high standards in sample processing.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Emerson Sample Handling System MicroCEM SHS

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Emerson Sample Handling System MicroCEM SHS

Create an account to install this asset package.

Maintenance Plans for Emerson Sample Handling System Model MicroCEM SHS

Integrate maintenance plans directly into your work orders in MaintainX.

6 Monthly Maintenance

- Inspect and clean Filter Element in Primary sintered metal sample filters. In case something happened, replace it

- Inspect and clean Filter Element in Sintered Metal Sample Guard Filters. In case something happened, replace it

- Inspect Seal Kit in Sintered Metal Sample Guard Filters. In case something happened, replace it

- Inspect Seal Kit in Sample Filters with Non-Metallic Elements. In case something happened, replace it

- Inspect Seal Kit in Sample Coalescing Filters with Non-Metallic Elements. In case something happened, replace it

- Inspect Seal Kit in Air Filters. In case something happened, replace it

- Inspect Seals in Rotary or Centrifugal Pump. In case something happened, replace it

- Test Sample Pressure Switches, Sample Flow Switches, Temperature Switches, Level Sensor Switches

- Inspect and test Transducers - E to I, Dual Alarm Modules, Sample Hold Modules;

Daily Maintenance

- Blowdown Primary sintered metal sample filters

- Visually check the indicator of the flowmeters

- Visually check the indicator of the pressure gauges

- Visually check the Coolant and/or Sample Temperature of the refrigerated condenser

- Visually check the Sample Temperature of the Thermo-Electric Cooler

- Visually check the Coolant and/or Sample Temperature of the Water Cooler/Water-Cooled Separator;

3 Monthly Maintenance

- Inspect the Element in Disposable End-of-Line Filters. In case something happened, replace it

- Inspect filter element in air filter. In case something happened, replace it

- Inspect and test Packing Adjustment in Regulating/Needle Valves/Toggle Valves

- Inspect and tighten Packing Adjustment Manual or Remote Operated Ball Valves - 2, 3, 4, or 5- Way

- Inspect Motorized Operators of the valves. In case something happened, replace it

- Inspect and clean Valves and Valve Seat of the Bellows Pump

- Inspect Bellows of the Bellows Pump

- Inspect Ammonia Scrubber. In case something happened, replace it;

12 Monthly Maintenance

- Inspect Seat and Seals in Regulating/Needle Valves/Toggle Valves. In case something happened, replace it

- Inspect O-Ring Seal, Spring of the Check/Relief Valves. In case something happened, replace it

- Inspect Plug Assembly. In case something happened, replace it

- Inspect Seat and Seals of the Packless Valve. In case something happened, replace it

- Inspect O-Rings of the Quick Connect Fittings. In case something happened, replace it

- Inspect O-Rings and Seals of the Flowmeter. In case something happened, replace it

- Inspect Snubbers of the Pressure Gauges. In case something happened, replace it

- Inspect Valve Seat and Diaphragm in the Sample Back-,Differential-, and Pressure Regulator. In case something happened, replace it

- Replace Regulator of the Air Service Pressure Regulators

Weekly Maintenance

- Blowdown Filter Element of the Y strainer

- Inspect the Heated/Vaporizing Pressure Regulating Stations

- Inspect the Heated Sample Line

- Inspect the Temperature Sensing Element

- Inspect the Temperature Controllers

- Inspect the Enclosure Heaters

- Inspect the Enclosure Air Conditioners

- Inspect the Enclosure Vent Fans

- Inspect the Enclosure Heat Exchangers

Parts for Emerson Sample Handling System MicroCEM SHS

Access the parts list for your equipment in MaintainX.

Relay Board Assembly

662210

Pressure Regulator

902238

Flowmeter

902127

4-Way Valve

905782

Power Supply

905796

Relay Board Assembly

662210

Pressure Regulator

902238

Flowmeter

902127

4-Way Valve

905782

Power Supply

905796

Relay Board Assembly

662210

Pressure Regulator

902238

Flowmeter

902127

4-Way Valve

905782

Power Supply

905796

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX