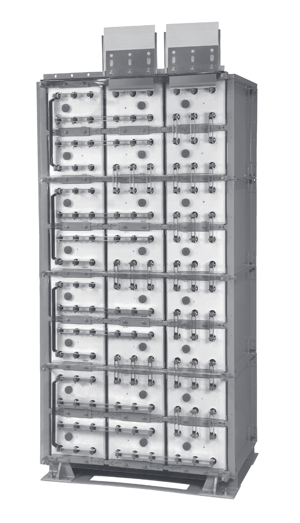

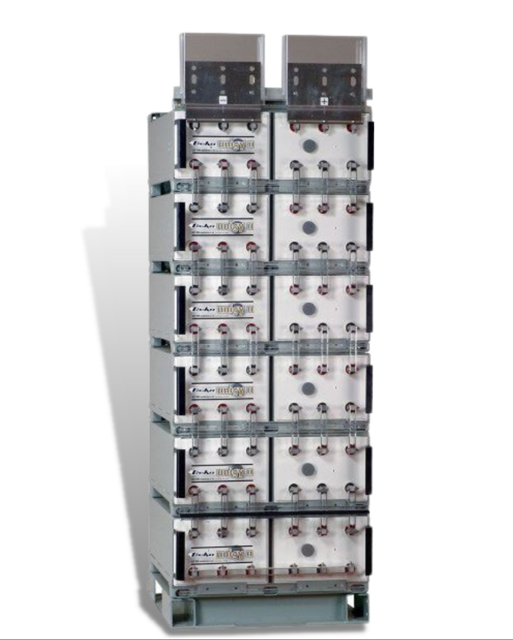

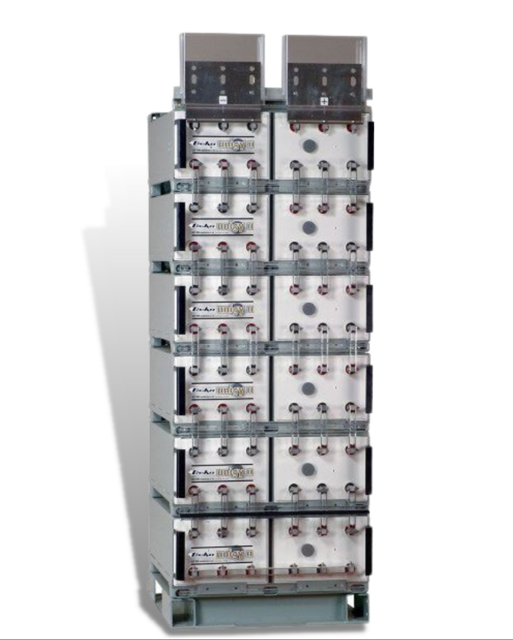

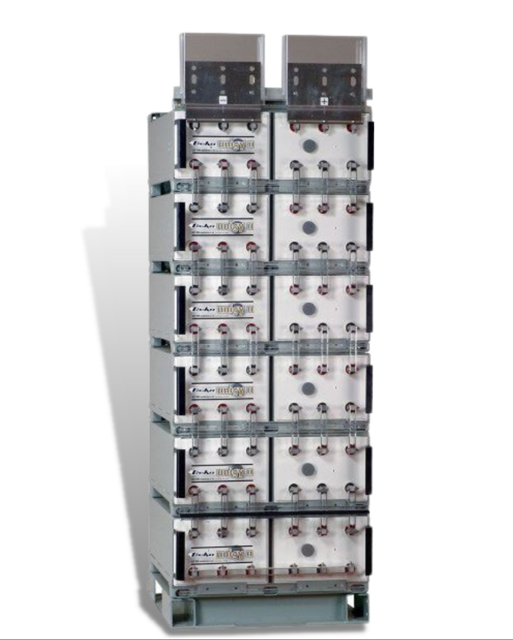

The East Penn Manufacturing Co. NB Module AVR125-33 is a high-performance automatic voltage regulator designed for reliable voltage stabilization in industrial applications. This model ensures optimal power quality and system protection, making it an essential component for efficient electrical management.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for East Penn Manufacturing Co. NB Module AVR125-33

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

East Penn Manufacturing Co. NB Module AVR125-33

Create an account to install this asset package.

Maintenance Plans for East Penn Manufacturing Co. NB Module Model AVR125-33

Integrate maintenance plans directly into your work orders in MaintainX.

Replacement

CELL REMOVAL PROCEDURE

1. Before removing cell, review Safety Precautions on pg. 2 of this manual. Contact East Penn Mfg. Company, Inc. with specific questions or concerns.

2. Remove one cell at a time.

3. Confirm the lifting device is rated to handle the weight of one cell.

4. All tools used to remove the cell shall be insulated to avoid metal contact with battery posts.

5. Remove bolts from the retainer bar from the cell to be replaced.

6. Cells develop internal pressure. Relieving this pressure from the cell will make it easier to remove the cell from the sleeve assembly.

a. Pry off the vent shroud

b. Remove the flame arrestor

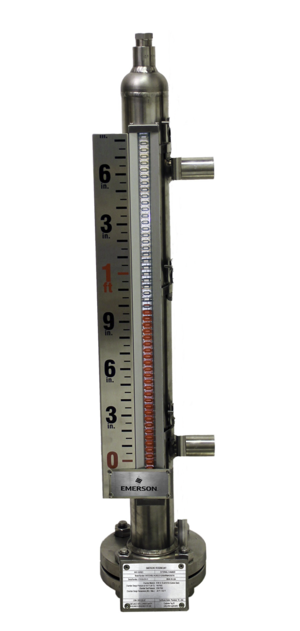

Inspection 1Y

1. Conduct a visual inspection of each cell.

2. Record the battery string voltage.

3. Record the charger voltage.

4. Record the individual cell voltages. The accuracy of the DMM (Digital Multimeter) must be .05% (on dc scale) or better. The DMM must be calibrated to NIST traceable standards.

Because float readings are affected by discharge and recharges, these readings must be taken when batteries have been on continuous, uninterrupted float for at least one month. Cells should be within ± 0.05 volts of the average cell float voltage.

5. Record the ambient temperatures.

6. Record individual cell Ohmic readings.

7. Record all intercell, inter unit and terminal connection resistances. Micro-ohm readings should be taken during this inspection. If any reading differs by more than 20% from initial readings taken, retorque the connection.; Recheck the micro-ohm reading. If the reading remains high, clean the contact surface according to installation portion of this manual.

Testing

Capacity Testing

Per IEEE 1188 “Capacity testing is used to trend battery aging. The result of a capacity test is a calculation of the capacity of the battery. The calculated capacity is also used to determine if the battery requires replacement.”

Do not discharge the batteries beyond the specified final voltage. When discharging at higher rates, extra connectors may need to be added to prevent excessive voltage drop and/or excessive temperature rise. Consult “Connector Packages” chart (pg. 15) for current limits.

When performing capacity testing and recording data use IEEE 1188 instructions. Should it be determined that any individual battery(ies) or cell(s) need to be replaced, contact your nearest East Penn agent or East Penn Service Center.

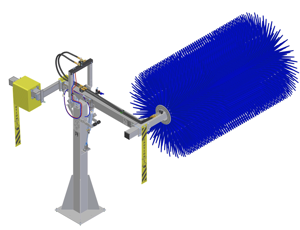

Cleaning

Battery Cleaning

Batteries, cabinets, racks, and modules should be cleaned with clear water or a mixture of baking soda and water or East Penn mfg. supplied battery cleaner (part # 00321). Use clean water to remove baking soda residue.

Never use solvents to clean the battery.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX