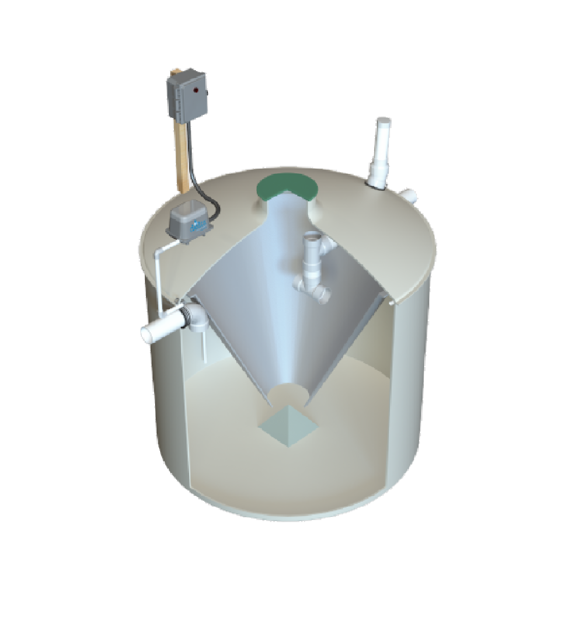

The Delta Electronics Wastewater Treatment System DF Series is engineered for efficient wastewater management. This advanced system combines innovative technology with reliable performance, ensuring optimal treatment processes for various industrial applications. Trust Delta Electronics for your wastewater treatment needs.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Delta Electronics Wastewater Treatment System DF Series

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Delta Electronics Wastewater Treatment System DF Series

Create an account to install this asset package.

Maintenance Plans for Delta Electronics Wastewater Treatment System Model DF Series

Integrate maintenance plans directly into your work orders in MaintainX.

Weekly Check

• Check the treatment plant for offensive odor. If such a condition should develop, call an authorized Delta Treatment Systems dealer/distributor.;

6 Monthly Maintenance

Performed by a certified service provider.

• Clean air filter on the air pump

• Inspect and make any necessary adjustments to mechanical and electrical components.

– Make sure all components are functioning properly, (alarms, switches, air pump, etc.).

• Inspect the color and turbidity of the effluent and check for any odor.

– No offensive odors should be present; an earthy odor is typical.

• Take a sample from the aeration tank and perform a 30-minute settleability test described in the “Solids Removal” section.

• Break up any sludge that may have developed in the clarifier so it can return to the aeration zone. Care should be taken to prevent solids from leaving the unit.

• The homeowner must be notified in writing if any improper operation is observed and cannot be corrected at the time of service.

Daily Inspection

• Observe the warning device, which comes on when the power to the air pump has been interrupted or when the air supply system has malfunctioned. If the alarm is activated, check for a blown fuse or thrown circuit breaker.

Check air pump to be sure it is operating. Once accustomed to the soft humming sound of a properly operating unit, any unusual noise is an indication of malfunction. If an unusual noise is detected or total failure is observed, call an authorized Delta Treatment Systems dealer/distributor.;

3 Monthly Maintenance

• The air filter on the air pump should be cleaned. Rinse with warm water if necessary. (See installation instructions.) Do not use oil or other solvents.;

Parts for Delta Electronics Wastewater Treatment System DF Series

Access the parts list for your equipment in MaintainX.

L-tube (2 required)

C50144

Service kit (2 required)

C50279

L-tube (2 required)

C50554

Shuttle assembly

C50159

Air filter

C56300

L-tube (2 required)

C50144

Service kit (2 required)

C50279

L-tube (2 required)

C50554

Shuttle assembly

C50159

Air filter

C56300

L-tube (2 required)

C50144

Service kit (2 required)

C50279

L-tube (2 required)

C50554

Shuttle assembly

C50159

Air filter

C56300

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX