Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

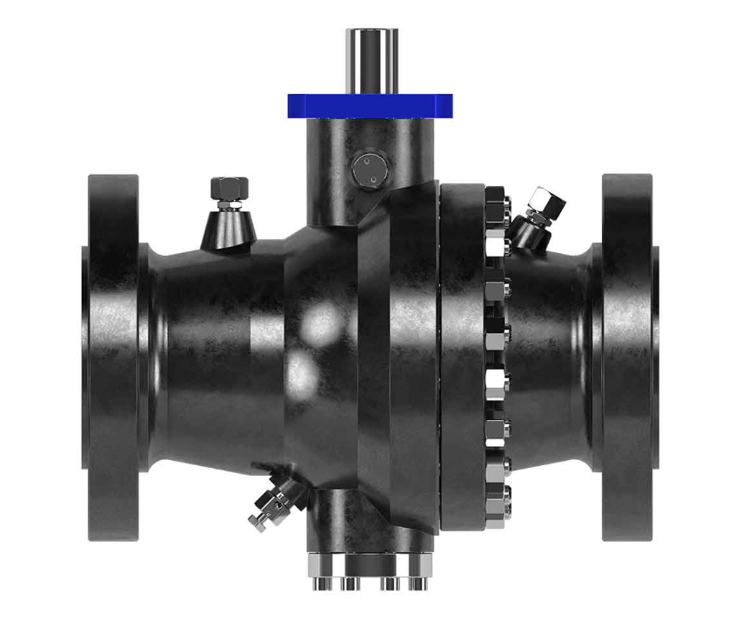

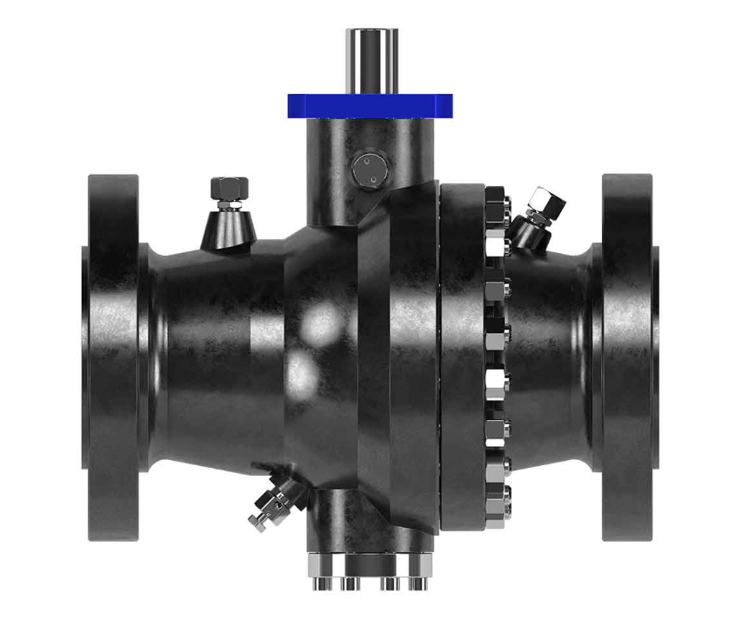

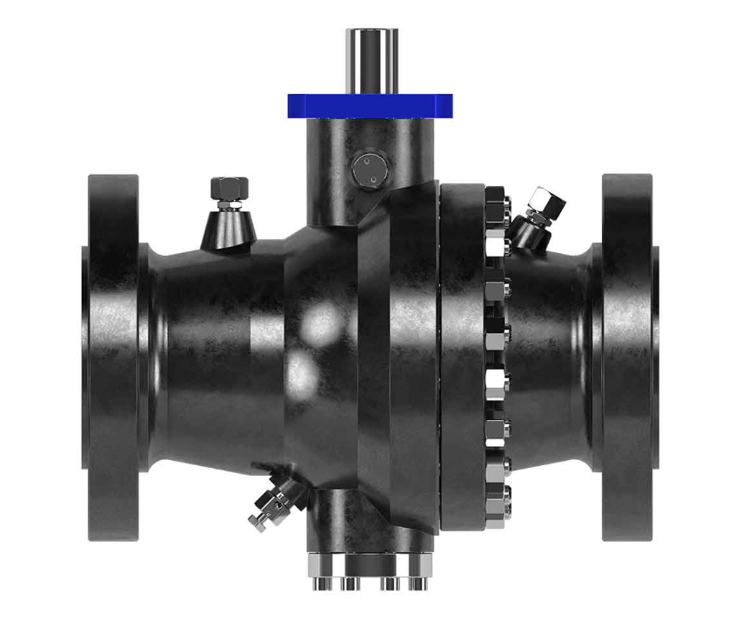

Manual for Cameron Ball Valve WKM 370D6

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Cameron Ball Valve WKM 370D6

Create an account to install this asset package.

Maintenance Plans for Cameron Ball Valve Model WKM 370D6

Integrate maintenance plans directly into your work orders in MaintainX.

Ball Valve Inspection

After cleaning, all valve components should be inspected for damage, dents, scoring, wear, or corrosion. If any damage is found, proceed with the repair where possible or with replacement of the parts.

For a complete inspection procedure, the following operations should be carried out:

1. Check the metallic parts for damage along the sealing surfaces and on moving surfaces. Particular attention should be paid to surface nicks and corner damage.

2. Make sure that the sealing rings and gaskets are not slashed, extruded and/or otherwise damaged.

3. Check for scratches and plating defects on the surfaces of the bearings, the thrust washers, the O-ring grooves, the ball, and the seat components.

4. Inspect all replacement components that are going to be used to ensure damage has not occurred in storage or transportation.

5. If any damage is found, the minor repairs should be carried out by trained personnel, otherwise contact WKM representative.

The minor repairs that may be carried out on site by maintenance personnel shall be in accordance with the following points:

1. Use standard engineering practices to repair the damaged metallic surfaces.

Ball Valve Drainage

Warning: This procedure requires trained personnel with PPE!

Valves may accumulate water, scale, deposits, and other foreign matter during their service. These materials may damage the valve in the following ways:

1. At low temperature, ice may form inside the valve and hinder its normal operation

2. Foreign matter may prevent the valve from fully closing and the ensuing throttling may damage the ball or the seat seals

3. Foreign matter may get caught between the ball and the seat and damage their surfaces

A drainage schedule is the best way to prevent damage caused by foreign matter. However, it is recommended that drainage should be carried out in the following cases:

1. Whenever the valve does not close

2. Before and during the cold season

3. After washing the line

Ball Valve Lubrication

Warning: This procedure requires trained personnel with PPE!

CAUTION: Grease fittings should not be removed if there is pressure in the line. Grease fittings should never be painted.

Is the valve in the fully open or fully closed position?

For 2”, 3”, and 4” Class 150 & 300 valves, lubrication is recommended in the fully open position.

Warning: Back up the seat grease fitting so only the safety vent cap will be removed from the fitting. Carefully remove the safety cap from the seat grease fitting. NEVER remove the grease fitting when the valve is under pressure.

Safety vent cap removed from grease fitting?

Grease gun connection attached onto grease fitting?

Sealant injected?

If injection of the sealant is difficult, flush the valve seats and attempt to inject sealant again.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX