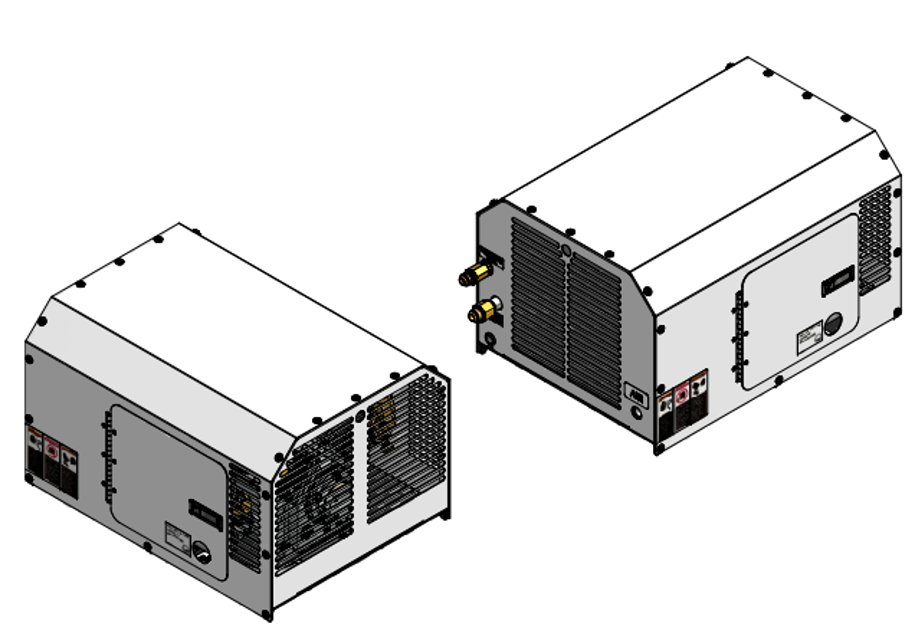

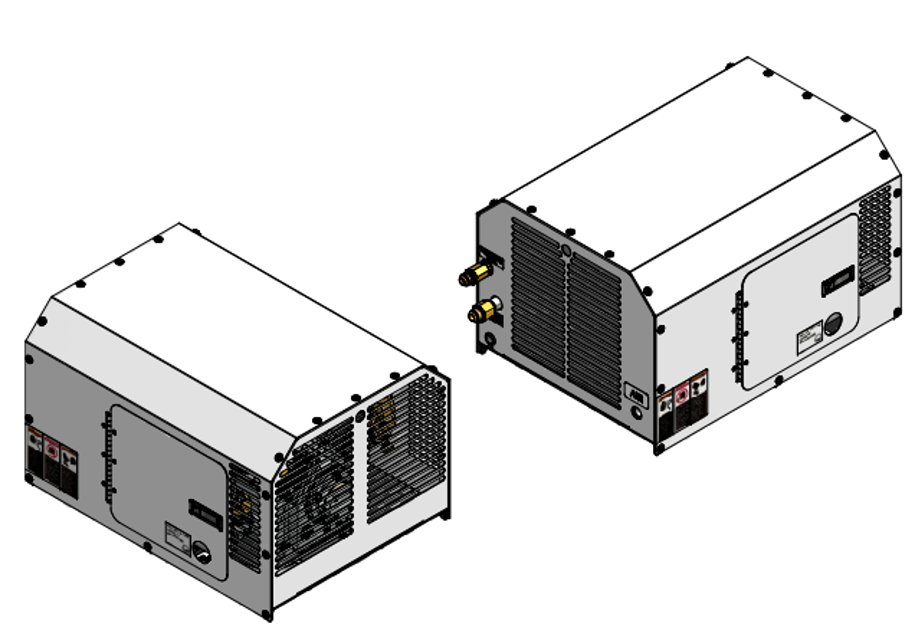

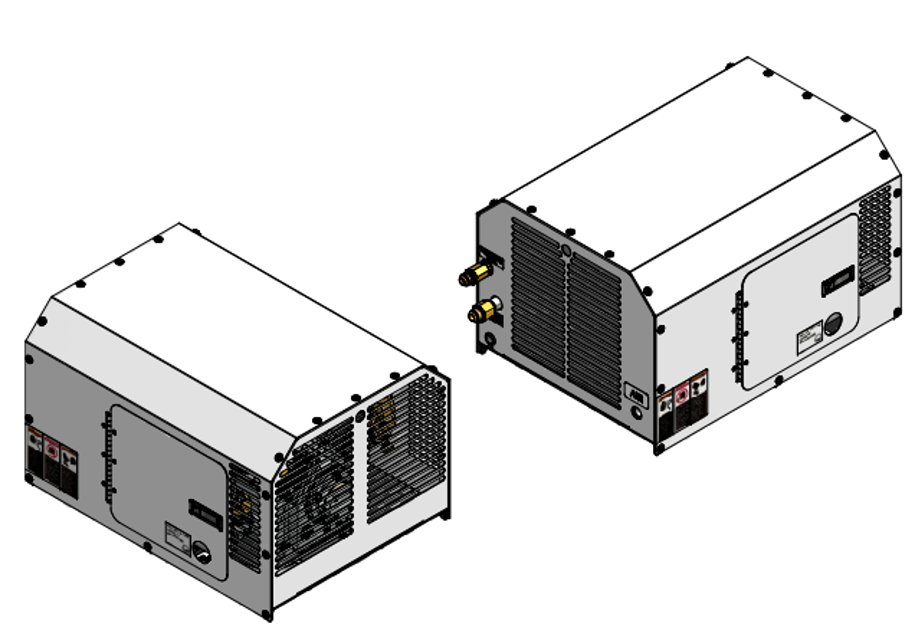

The Boss Hydraulic Air Compressor K36BP is a robust piston-type compressor designed for industrial applications. Known for its reliability and efficiency, this model provides powerful air compression solutions suitable for various tasks in demanding environments. Optimize your operations with the K36BP's advanced features and durable construction.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Boss Hydraulic Air Compressor K36BP Piston

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Boss Hydraulic Air Compressor K36BP Piston

Create an account to install this asset package.

Maintenance Plans for Boss Hydraulic Air Compressor Model K36BP Piston

Integrate maintenance plans directly into your work orders in MaintainX.

Maintenance 1W

WEEKLY

1. Inspect the air intake.

2. Check the cylinder head stud torque (see NOTE 2).

3. Check the operation of the receiver safety valves.;

Maintenance 3M

EVERY 3 MONTHS

1. Change the crankcase oil (see NOTE 1).

2. Check cooler fins for dirt and obstruction. Clean if needed.;

Maintenance

Air Intake Filter (P/N 308157)

The air intake filter is a heavy-duty dry type high efficiency filter designed to protect the compressor from dust and foreign objects.

Frequency of maintenance of the filter depends on dust conditions at the operating site. The filter element must be serviced when clogged. A clogged air filter element will reduce compressor performance and cause premature wear of components.

Hydraulic Oil Cooler

The interior of the oil cooler should be cleaned when the pressure drop across it at full flow exceeds 25 PSI.

1. Remove cooler.

2. Circulate a suitable solvent to dissolve and remove varnish and sludge.

3. Flush generously with hydraulic oil.

4. Once the cooler is reinstalled, fill the hydraulic system with the proper fluid to their appropriate levels.

Oil Replacement

Compressor Oil Fill, Level, and Drain

Before adding or changing compressor oil, make sure that the compressor is completely relieved of pressure. Oil is added at the fill cap on the side of the compressor body. A drain line is located opposite the service door. The proper oil level is in the middle of the oil sight glass, when the unit is shut down and has had time to settle. The truck must be level when checking the oil. DO NOT OVERFILL. The oil capacity is given in “Compressor Specifications”.;

Maintenance 1D

DAILY

1. Check crankcase oil level. Add if needed.

2. Drain condensation from air receiver.;

Parts for Boss Hydraulic Air Compressor K36BP Piston

Access the parts list for your equipment in MaintainX.

Clamp, Hose

304957

Kit, Repair Hyd Motor Seal

302936

Filter, Air

308217

Tee

902203-032

Plug, Pipe

902915-040

Clamp, Hose

304957

Kit, Repair Hyd Motor Seal

302936

Filter, Air

308217

Tee

902203-032

Plug, Pipe

902915-040

Clamp, Hose

304957

Kit, Repair Hyd Motor Seal

302936

Filter, Air

308217

Tee

902203-032

Plug, Pipe

902915-040

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX