Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

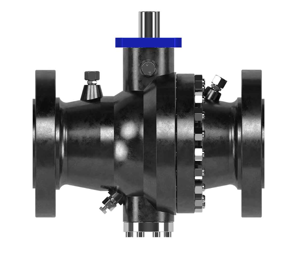

Bettis Rack and Pinion Pneumatic Actuator RPE0350U

Create an account to install this asset package.

Maintenance Plans for Bettis Rack and Pinion Pneumatic Actuator Model RPE0350U

Integrate maintenance plans directly into your work orders in MaintainX.

Rack / Pinion Pneumatic Actuator Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Enter the number of cycles completed by the actuator

Visual inspection of the entire actuator and control system passed?

No leaks on the actuator parts under pressure?

Pneumatic connections checked for leaks?

Manual override checked and is regular?

Pneumatic filter cartridge is sound and filter bowl cleaned properly?

Relief valves setting checked?

Enter the power fluid supply pressure value

Pinion Removal

Warning: This procedure requires trained personnel with PPE!

Circlip (27) and thrust bearing (23) removed

Top pinion bearing (19) removed (for sizes 950 to 4000)

Pinion (18) removed by pushing it downwards

Backup ring (29), O-ring pinion top (21), cam (24) and cam thrust washer (25) removed (for Size 4000)

Pinion O-ring seals (21/22) and the pinion bearings (19/20) removed

Backup ring (29) removed (for Size 950 to 2500)

All removed parts discarded

Sign off on the pinion removal

Actuator From The Valve Removal

Disconnect all air supply hoses (Ports A and B or solenoid)

Disconnect all electrical wirings of the switch box

Disconnect the electrical wiring of the solenoid valve

Remove the bolts and nuts from the valve flange

Remove the bracket from the actuator

Remove the switch box and solenoid valve. Refer to the documentation of the switch box and solenoid valve for safe disassembly

Sign off on the actuator removal

End Cap Removal

1. For Double-Acting actuators, do the following:

a. Remove the screws (8) and washers (10) of the end caps (6).

b. Remove the o-ring (11) and "B" port seal (2). Discard these parts.

Double acting end caps (6) are fitted with a white warning sticker. Spring return end caps (5) are fitted with a black warning sticker.

Actuator sizes 25 to 100 have high end caps for double-acting and spring-return models.

Actuator sizes 150 to 4000 have low end caps for double-acting models and high end caps for spring return models.

2. For Spring-Return actuators, do the following:

a. Tip: For actuators with assembly code CW, turn back the right hand limit stop screw (30) 2 full turns.

For actuators with assembly code CC, turn back the left hand limit stop screw (30) 2 full turns.

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX