Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

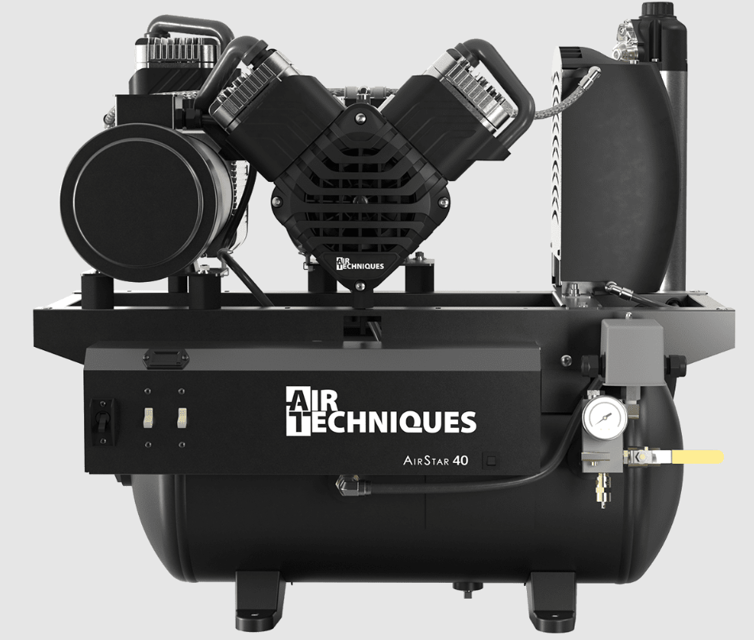

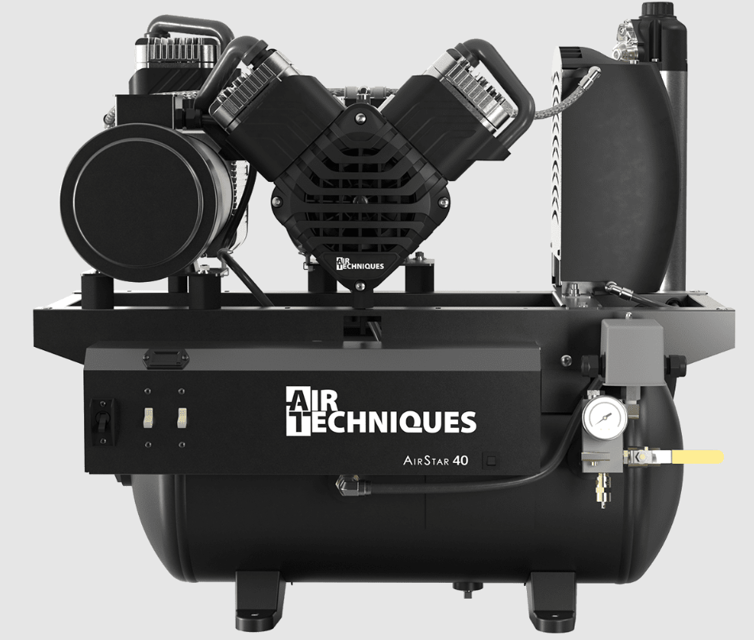

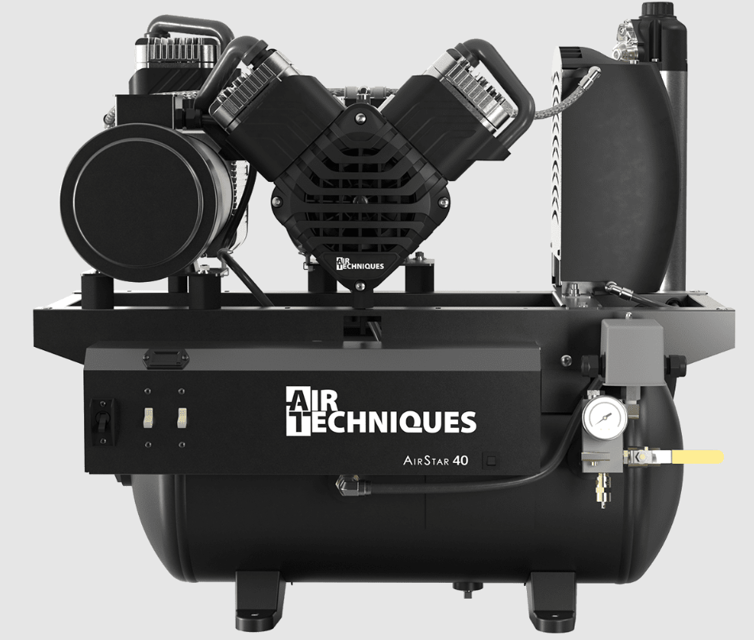

Manual for Air Techniques Air Compressor AS40

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Air Techniques Air Compressor AS40

Create an account to install this asset package.

Maintenance Plans for Air Techniques Air Compressor Model AS40

Integrate maintenance plans directly into your work orders in MaintainX.

Post Installation Check

Make Sure Everything Is Running Properly

After your AIRSTAR has been installed and before it is put into operation, be sure to follow the check-out procedure detailed below:

Check that Intake Filter(s) are fully seated into the compressor head(s) and that the Tank Outlet Valve is closed.

Turn on the electricity. Check the incoming line voltage. It should be at least 108 Volts for the AS10 and AS21; and 198 Volts for the AS12, AS22, AS30, AS40, AS50, AS70 and AS100. This voltage should remain at or above these levels while the AIRSTAR is running. If not, install the appropriate boost transformer and check that the correct main circuit breaker and wire size are being used.

Check pump-up and recovery times as detailed below and compare to the times in the table.

Turn on the AIRSTAR’s power and determine the pump-up time from 0-115 PSI. See the table below.

Drain the storage tank to 80 PSI and determine the recovery time from 85 to 115 PSI. See the table below.;

1 Monthly Air Compressor Inspection

Clean exterior surfaces

Check for abnormal noises and air leaks

No flammable, corrosive, or combustible materials are stored in the equipment room (especially in the area around the equipment)

Operational range of pressure switch

Inspect the Moisture Monitor for a color change

Note: To comply with NFPA 99C, a 5-micron Filter is installed on the output of all AIRSTAR models.

Sign off on the inspection

1 Yearly Air Compressor Inspection

Refer to Figure 4 and check the Service Indicator on the 5-micron Outlet Filter.

Service Indicator

Red indicates that the filter must be replaced P/N 87168.

Green indicates No service is required.

Important: In dusty environments, the Intake Filter, PN 89938, may need to be changed more often than once a year.

Was the filter replaced?

Always dispose of the removed filter in accordance with local codes;

Sign off on the air compressor inspection

Parts for Air Techniques Air Compressor AS40

Access the parts list for your equipment in MaintainX.

5 Micron Replacement Filter

87168

Intake Filter

89938

Top Membrane Filter

87366

Compressor Air Intake Filters

89938R

Bottom Membrane Filter

87367

5 Micron Replacement Filter

87168

Intake Filter

89938

Top Membrane Filter

87366

Compressor Air Intake Filters

89938R

Bottom Membrane Filter

87367

5 Micron Replacement Filter

87168

Intake Filter

89938

Top Membrane Filter

87366

Compressor Air Intake Filters

89938R

Bottom Membrane Filter

87367

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX