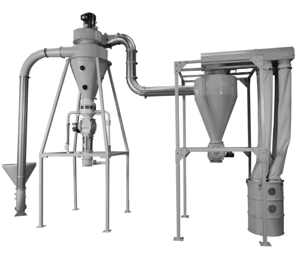

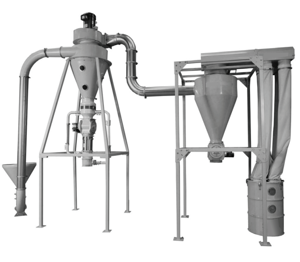

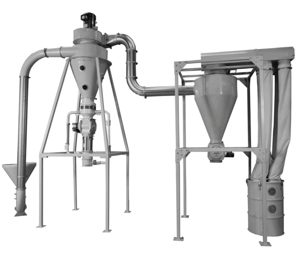

The Piovan Group Shredder Rollfeed RFL-69 is a robust industrial shredder designed for efficient material processing. This model excels in durability and performance, making it ideal for various applications in recycling and waste management. Regular maintenance ensures optimal operation and longevity of the equipment.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Piovan Group Shredder Rollfeed RFL-69

Create an account to install this asset package.

Maintenance Plans for Piovan Group Shredder Rollfeed Model RFL-69

Integrate maintenance plans directly into your work orders in MaintainX.

1 Monthly Lubrication

- Lubricate bearings

- 3 ounces as required amount of oil

- During 24 hours of operation

- The frequency of lubrication is in direct proportion to the hours of actual granulator operation

- Use of SKFGRA-TM3 grade 3MLGI grease or a type that is compatible;

3 Monthly Lubrication

- Lubricate bearings

- 1 ounce to 1/4 of tube amount of oil

- During 8 hours of operation

- The frequency of lubrication is in direct proportion to the hours of actual granulator operation

- Use of SKFGRA-TM3 grade 3MLGI grease or a type that is compatible;

Shredder Inspection

- Periodically check the tension of the drive belts. Disconnect and lock out power per standard procedures. To access the belts, remove the belt guard cover plate and rear sound enclosure. Always maintain proper belt tension and care. Adjust the motor tensioning bolts in order to tension the drive belts;

6 Weekly Lubrication

- Lubricate bearings

- 2 ounces as required amount of oil

- During 16 hours of operation

- The frequency of lubrication is in direct proportion to the hours of actual granulator operation

- Use of SKFGRA-TM3 grade 3MLGI grease or a type that is compatible;

Parts for Piovan Group Shredder Rollfeed RFL-69

Access the parts list for your equipment in MaintainX.

Side Plate

100620022M10A

Mobile Drive Roller

100610012M20A

Retaining Ring

5MECSEGW51250

Sheet Protection

10062018M10A

Fixed Drive Roller

100610012M10A

Side Plate

100620022M10A

Mobile Drive Roller

100610012M20A

Retaining Ring

5MECSEGW51250

Sheet Protection

10062018M10A

Fixed Drive Roller

100610012M10A

Side Plate

100620022M10A

Mobile Drive Roller

100610012M20A

Retaining Ring

5MECSEGW51250

Sheet Protection

10062018M10A

Fixed Drive Roller

100610012M10A

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX