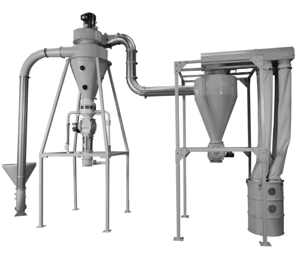

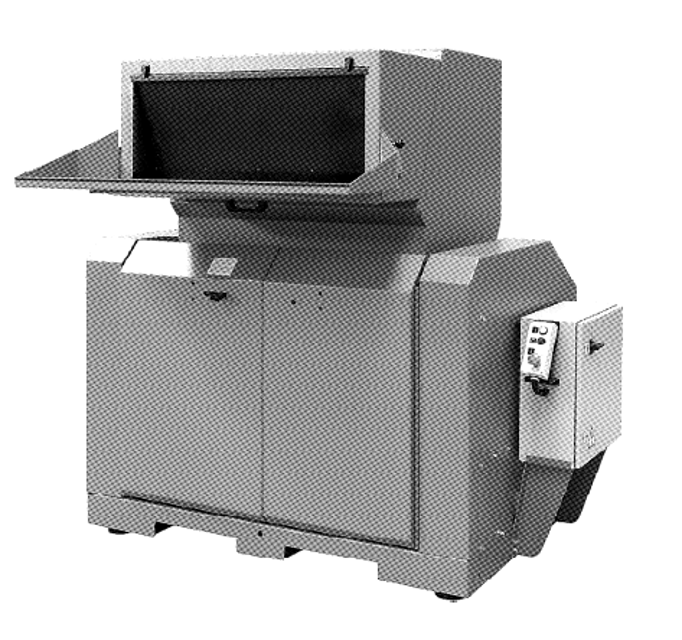

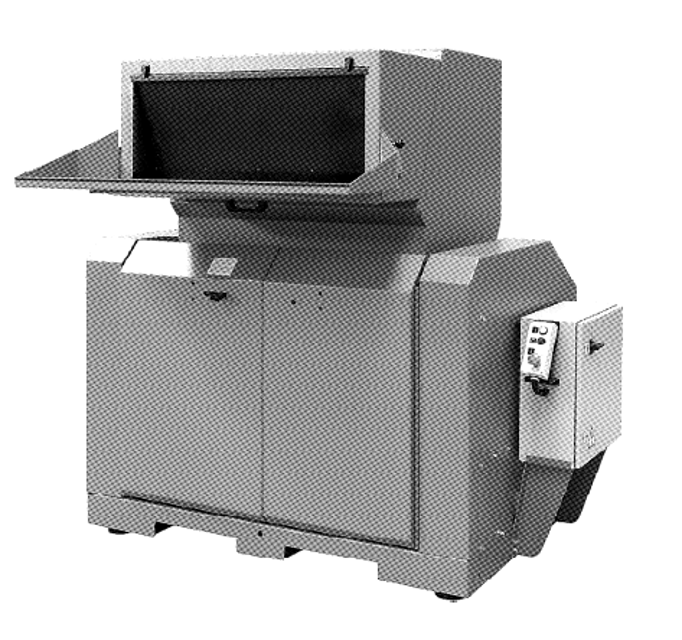

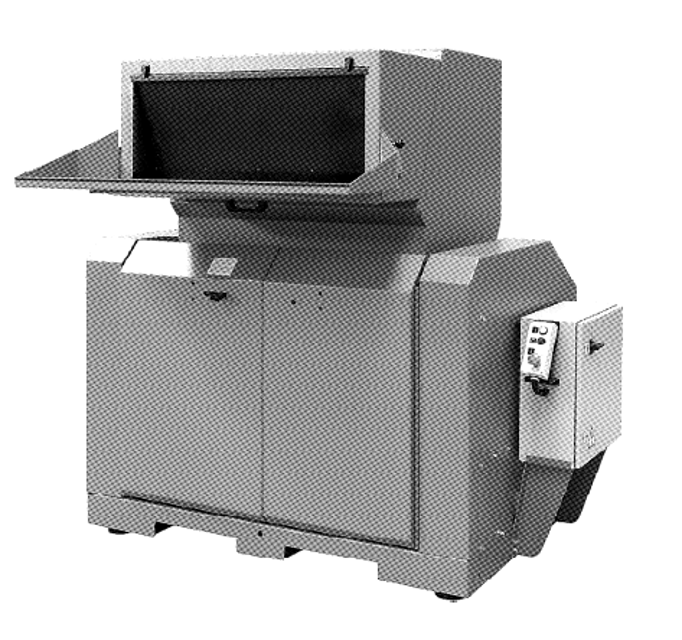

The Piovan Group Tangential Feed Granulator CG-1436 is a high-performance industrial granulator designed for efficient material processing. This robust equipment ensures optimal granulation and is essential for various manufacturing applications, enhancing productivity and material quality.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Piovan Group Tangential Feed Granulator CG-1436

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Piovan Group Tangential Feed Granulator CG-1436

Create an account to install this asset package.

Maintenance Plans for Piovan Group Tangential Feed Granulator Model CG-1436

Integrate maintenance plans directly into your work orders in MaintainX.

1000 Hours or 1 Yearly Lubrication

- Lubricate Granulator bearings

- Lubricate cutting chamber

- Lubricate Electric motor;

6 Monthly Inspection

- Check the V-belt tension;

1 Daily Inspection

- Flaps in the hopper. Check that the flaps are undamaged. Replace damaged flaps at once. Damaged flaps can drop down into the cutting chamber and damage the knives. Damaged flaps also entail the risk of material ejection

- Emergency stop. Check the emergency stop function. Start the granulator and stop it with the emergency stop(s). Reset. Turn the stop button in the direction of the arrow (counterclockwise);

1 Monthly Inspection

- Check that the V-belts are undamaged

- Check the V-belts for damage (page 27);

1 Weekly Inspection

- Cables. Check the electric cables of the machine for wear or other damage. Replace damaged cables at once

- Safety switches. Check the safety switch functions

- The 1436 granulator has one safety switch at the hopper, between the hopper and cutting chamber

- Check the hopper ́s safety switch. Open the doors, undo and fold out the hopper lock clasps. Close the doors and try to start the granulator. You should not be able start the granulator before the hopper and doors are closed

- Check the time delay at opening of the doors;

Parts for Piovan Group Tangential Feed Granulator CG-1436

Access the parts list for your equipment in MaintainX.

Grinding Jig

3-29280

Cutting Chamber

3-37003

Cutting Chamber

3-37000

Back Side

4-37009

Ring

4-08864

Grinding Jig

3-29280

Cutting Chamber

3-37003

Cutting Chamber

3-37000

Back Side

4-37009

Ring

4-08864

Grinding Jig

3-29280

Cutting Chamber

3-37003

Cutting Chamber

3-37000

Back Side

4-37009

Ring

4-08864

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX