The Lincoln Electric Welding Inverter POWER MIG 200 is a versatile and efficient welding machine designed for both professional and hobbyist applications. With its advanced inverter technology, this model delivers reliable performance and precise control for various welding tasks. Ideal for MIG welding, it ensures high-quality results and ease of use.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Lincoln Electric Welding Inverter POWER MIG 200

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric Welding Inverter POWER MIG 200

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric Welding Inverter Model POWER MIG 200

Integrate maintenance plans directly into your work orders in MaintainX.

Drive Rolls and Guide Plate Maintenance

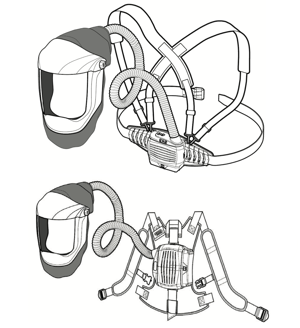

Warning: This maintenance check requires trained personnel with PPE!

Wire drive mechanism inspected after every coil of wire?

Drive mechanism cleaned with low pressure compressed air?

Warning: Do not use solvents for cleaning the idle roll because it may wash the lubricant out of the bearing

Select the wire size used

Drive roll changed if a wire size other than that stamped on the roll is used?

Sign off on the drive rolls and guide plate maintenance

General Welding Inverter Maintenance

Warning: This maintenance check requires trained personnel with PPE!

Is the welder running hot?

If the welder is running hot, it may be due to clogged air passages. Proceed with the following steps.

Blow dirt out of the welder with low-pressure air

Note: The fan motors have sealed ball bearings which require no service.

Replace worn contact tips as required

Remove spatter from inside of gas nozzle and from tip after each 10 minutes of arc time or as required

Sign off on the welding inverter maintenance

Gun Cable Cleaning

Warning: Ensure to wear safety goggles and gloves before starting the procedure

Enter the amount of electrode used

Cable removed from the wire feeder?

Contact tip removed from the gun?

Cable liner cleaned with air hose from the gas diffuser end?

Sign off on the gun cable cleaning

Liner Replacement

Warning: Ensure the machine is turned off and cooled down before starting the procedure

Gas nozzle and nozzle insulator removed?

Set screw in the gas diffuser located?

Set screw loosened with a 5/64\ (2.0 mm) Allen wrench?"

Gas diffuser removed from the gun tube?

Gun and cable laid out straight on a flat surface?

Set screw in the brass connector loosened and old liner pulled out?

New untrimmed liner inserted into the connector end of the cable?

Liner bushing stencilled appropriately for the wire size being used?

Parts for Lincoln Electric Welding Inverter POWER MIG 200

Access the parts list for your equipment in MaintainX.

Welding Gun

K533-2

Drive Roll kit

KP1696-045S

Drive Roll kit

KP1697-035C

Contact Tips

S19393-5

Drive Roll kit

KP1696-030S

Welding Gun

K533-2

Drive Roll kit

KP1696-045S

Drive Roll kit

KP1697-035C

Contact Tips

S19393-5

Drive Roll kit

KP1696-030S

Welding Gun

K533-2

Drive Roll kit

KP1696-045S

Drive Roll kit

KP1697-035C

Contact Tips

S19393-5

Drive Roll kit

KP1696-030S

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX