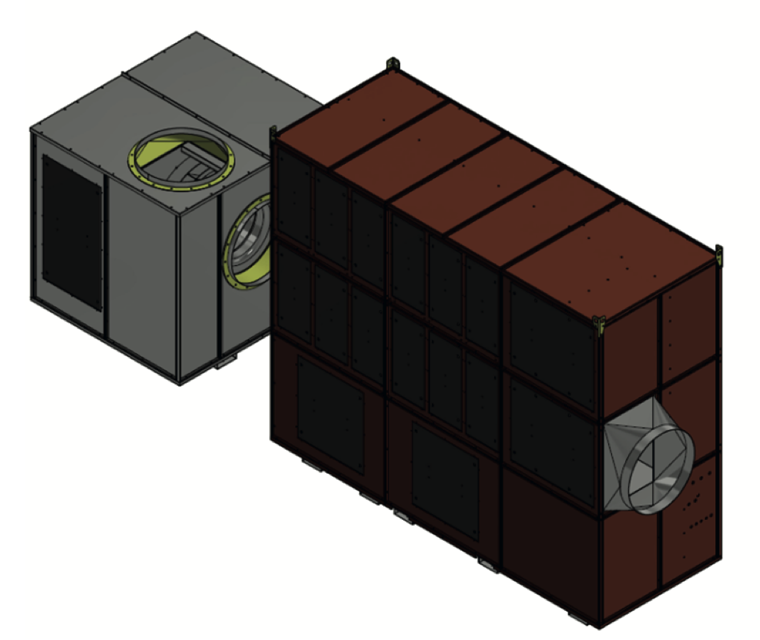

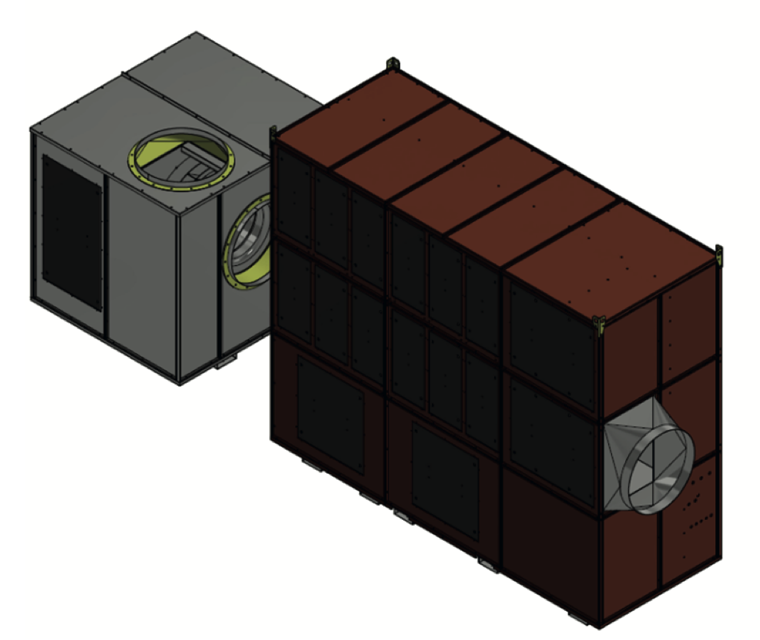

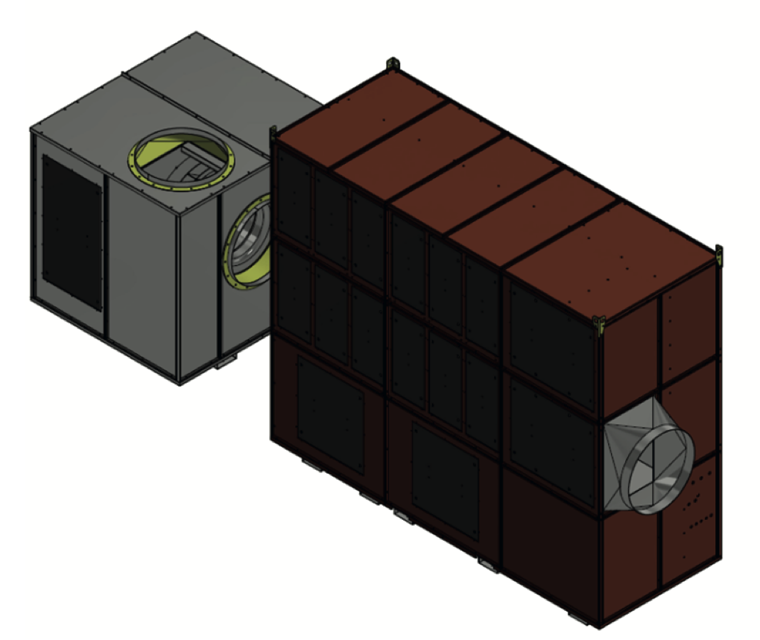

The Lincoln Electric Filtration Unit Digifilter 20CD is a high-performance filtration system designed to enhance air quality in industrial environments. This advanced unit effectively removes contaminants, ensuring optimal operation and longevity of equipment. Ideal for various applications, it combines reliability with innovative technology for superior filtration performance.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Lincoln Electric FILTRATION UNIT Digifilter 20CD

Create an account to install this asset package.

Maintenance Plans for Lincoln Electric FILTRATION UNIT Model Digifilter 20CD

Integrate maintenance plans directly into your work orders in MaintainX.

Unclogging Components Inspection

- Inspect the proper working and position of the unclogging solenoid valves while replacing filter cartridges

- They must be placed along the centre line of the cartridges near the unclogging mechanism and not have any air leaks.

Dust Container Emptying

- Switch off the power to the fan

- Open the dust container compartment

- Take off the holding latches; - Remove the container using equipment appropriate for the weight of the whole. If there is a bag, replace the bag inside and put the container in its place

- Take the bulk bag off the hopper

- Make a knot to close the bulk bag before handling

- Remove the bulk bag using equipment appropriate for the weight of the whole

- Put the new bulk bag in place under the hopper and attach it to the hopper so that it is sealed

- Put the unit back into service.

Electrical Maintenance

- Regularly check the cables and connections

- Tighten the screw connections

- Worn cables must be replaced.

Fan Maintenance

- Check that dust is not being deposited in large quantities on the motor ventilation blades

- Check that dust is not being deposited in large quantities on the ixed and rotating parts of the fan

- Clean if necessary.

Pneumatic Maintenance

- The filter must be purged regularly

- The air supply pipes must be inspected (for leaks) and changed if necessary;

Parts for Lincoln Electric FILTRATION UNIT Digifilter 20CD

Access the parts list for your equipment in MaintainX.

Variable Frequency Drive

-

Relay

-

Additional Vertical Discharge

EM61000072

Inlet To The Left

EM61000024

Green: Filter Operating

-

Variable Frequency Drive

-

Relay

-

Additional Vertical Discharge

EM61000072

Inlet To The Left

EM61000024

Green: Filter Operating

-

Variable Frequency Drive

-

Relay

-

Additional Vertical Discharge

EM61000072

Inlet To The Left

EM61000024

Green: Filter Operating

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX