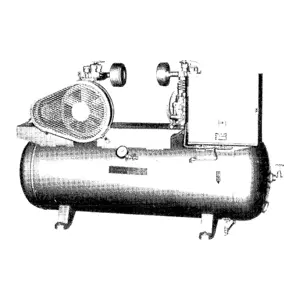

The Honeywell Burner WX0850 is a high-performance industrial burner designed for efficient combustion and reliable operation. This model is ideal for various applications, ensuring optimal fuel efficiency and safety in industrial environments. Regular maintenance is essential to maximize its lifespan and performance.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Honeywell Burner WX0850

Create an account to install this asset package.

Maintenance Plans for Honeywell Burner Model WX0850

Integrate maintenance plans directly into your work orders in MaintainX.

1 Yearly Maintenance

Yearly checklist 1 Test (leak test) safety shut-off valves for tightness of closure

2 Test air pressure switch settings by checking switch movements against pressure settings and comparing with actual impulse pressure

3 Visually check ignition cable and connectors

4 Inspect impulse piping for leaks

5 Clean and inspect all the burners

6 Make sure that the following components are not damaged or distorted: – burner nozzle – spark plugs – flame sensors – flame tube or combustion block

7 If applicable, remove and clean all the orifice plates;

1 Monthly Maintenance

Monthly checklist: 1 Inspect flame-sensing devices for good condition and cleanliness

2 Check for proper inlet air/gas ratios

3 Test all the alarm systems for proper signals

4 Check ignition spark plugs and proper gap

5 Check valve motors and control valves for free, smooth action and adjustment

6 Check for proper operation of the ventilating equipment

7 Test the interlock sequence of all safety equipment, manually make each interlock fail, noting that related equipment closes or stops as specified by the manufacturer

8 Test flame monitoring control system by manually shutting off gas to burner

9 Test main fuel hand-valves for operation

Inspection

The nozzle can be inspected without removing the burner from thechamber wall or entering the chamber. Perform the following: 1 Shut the burner off and manually close the main gas shut off cocks

2 Allow the chamber temperature to cool down to 250°F (121°C). 3 Disconnect the gas piping at a union or the gas inlet flange provided on the burner

4 Remove the four bolts

CAUTION – Do not attempt to remove the rear cover by removing the inner circle bolts. Internal burner parts will be damaged

5 Remove bolts

6 Remove the rear cover / nozzle assembly from the burner housing

7 To reassemble, follow this sequence in the reverse order

Note: The combustor can be inspected only by removing the burner from the chamber wall or entering the chamber;

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX