Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

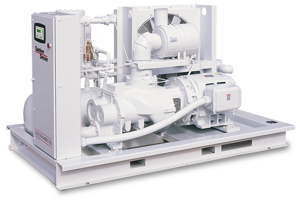

Gardner Denver Air Compressor EAH99D

Create an account to install this asset package.

Maintenance Plans for Gardner Denver Air Compressor Model EAH99D

Integrate maintenance plans directly into your work orders in MaintainX.

1000 Hourly Oil Filter Element Replacement

COMPRESSOR OIL FILTER - This screw on oil filter is a vital part in maintaining a trouble-free compressor, since it removes dirt and abrasives from the circulated oil. The oil filter relief valve is located in the oil filter head. The relief valve opens in the event the element becomes dirty enough to block the flow of oil.

Use only the replacement element shown on the filter tag or refer to the parts list for the part number.

Stop the unit and be sure no air pressure is in the oil reservoir.

Remove the spin-on element.

Clean the gasket face of the filter body.

Coat the new element gasket with clean lubricant used in the unit.

Screw the new element on the filter body and tighten by hand. DO NOT OVER TIGHTEN THE ELEMENT.

Run the unit and check for leaks.

Sign off on the oil filter element replacement

50 Hourly Filter Element Cleaning

HEAVY-DUTY AIR FILTER furnished as standard equipment on units with an enclosure is a heavy-duty washable element dry type air filter. The air filter must receive proper maintenance if maximum service is to be obtained from the unit. Establishing adequate and timely filter service is MOST IMPORTANT. An improperly maintained air filter can cause a loss of compressor air delivery.

Filter Element - Clean every 50 to 150 operating hours depending on dust conditions.

NOTICE

Use only genuine Gardner Denver air filter elements on Gardner Denver compressor units. Genuine parts are available through your authorized Gardner Denver distributor.

To service:

1. Remove the wingnut and pull out the filter element.

2. Visually inspect the element. If cleaning is not necessary, reinstall the filter element. If the element requires cleaning, follow steps 3, 4 and 5.

3. Wash the element by soaking about 15 minutes in warm water with a mild non-sudsing detergent.

Rinse the element thoroughly with clean water; a hose may be used if the water pressure does not exceed 40 psig (2.8 bar).

8 Hourly Air Compressor Inspection

Reservoir oil level

Unit loads and unloads properly

Discharge pressure

Discharge temperature

Check Panel LED’s for advisories

Sign off on the air compressor inspection

Air Compressor Inspection

Oil Separator - Operating conditions determine frequency of service.

ADDITION OF OIL BETWEEN CHANGES must be made when the oil level is in the red range on the gauge as read while the unit is on. To add oil, follow these steps:

1. Be sure the unit is completely off and that no air pressure is in the oil reservoir.

2. Disconnect, lockout and tagout the power supply to the starter.

3. Wipe away all dirt around the oil filler plug.

4. Remove the oil filler plug and add oil as required to return the oil level to the center of the green range on the gauge.

5. Install the oil filler plug, restore power, run and check for leaks.

LUBRICANT CHANGE PROCEDURE - Following are the primary steps to be completed when upgrading or changing the type of lubricant.

1. Thoroughly drain system:

Parts for Gardner Denver Air Compressor EAH99D

Access the parts list for your equipment in MaintainX.

Oil Separator Kit

200EAP4013

Control Group

200ECM4002

Oil Separator Kit

200EAP4013

Control Group

200ECM4002

Oil Separator Kit

200EAP4013

Control Group

200ECM4002

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX