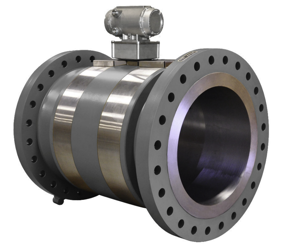

The Boss Water System XPOT XP is a robust water management solution designed for industrial applications. This system ensures optimal water quality and efficient operation, making it ideal for various sectors. Regular maintenance and quality spare parts are essential for maximizing the performance of the XPOT XP model.

Turn manuals into instant answers

with your AI-powered assistantTurn manuals into instant answers

with your AI-powered assistant

Manual for Boss Water System XPOT XP

Complete asset maintenance, one click away

Get instant access to all the maintenance information you need. Empower technicians to perform preventive maintenance with asset packages, ready to use right out of the box.

Documents & Manuals

Find all the essential guides in one place.

Tensioning Guide

Belt-diagram

C-120 pulleys

+ 13 more

Work Order Templates

Pre-built workflows to keep your asset running smoothly.

Daily Electrical System Inspection

Replace Roller and Pulley

Install Engine B-120

+ 29 more

Procedures

Integrate maintenance plans directly into your work orders.

Motion Industries

Applied Industrial Technologies

Electrical Brothers

+ 5 more

Parts

Access the parts list for your equipment in MaintainX.

Drive Motor

B2 Rollers

Tensioning System

+ 40 more

Boss Water System XPOT XP

Create an account to install this asset package.

Maintenance Plans for Boss Water System Model XPOT XP

Integrate maintenance plans directly into your work orders in MaintainX.

Replacement

The filter replacement may only be carried out when the X-POT XP+ is shut down and the BOSS X-POT XP+ has been hydraulically isolated from the main system water pressure and electrically isolated from the main system power supply. The X-POT XP+ equipment must be taken out of service and guarded against un-intentional re-starting until the maintenance work is finished.;

Inspection

At the end of the lifespan or at the planned decommissioning of the equipment please make sure that:

• The control panel is separated from the power supply.

• The hydraulic system connections and top-up connections should be closed off.

Caution: Water areas should first be vented and then emptied. This water may be conditioned, contain anti-freeze or other substances and as such must be disposed of in accordance with the local legislative requirements.

The destination of and further processing of the construction components should be carried out in agreement with the relevant waste management service provider.;

Cleaning

To manually dose the system, it may only be carried when the system is shut down and the BOSS™ X-POT XP+ has been hydraulically isolated from the main system water pressure and also electrically isolated from the main system power supply.

The X-POT XP+ equipment must be taken out of service and guarded against un-intentional re-starting until the Water Treatment Additives are dosed into the X-POT XP+ Vessel (4).

Dosing of Water Treatment Additives can only be achieved when the main System Pumps are operational, make sure they are working and the system is running.

3. Manually Dosing the System with Treatment Additives

1. The operative must wear protective gloves and eyewear for this operation.

2. Use of the main BOSS™ X-POT XP+ Schematic (page 10) is required to follow the main Item Numbers.

3. Turn the power off to the BOSST X-POT XP+ unit by turning the Mains ON/OFF Power Switch (22) through 90°.

4. Check to see the power is off, the power to the Grundfos CRIE Smart E-Pump (21). The screen should be blank and off and the pump will not run.

5. Manually close the 2"" Isolating Valves (1 & 3) on the Dirty Flow to the BOSS™ X-POT XP+.

Maintenance

1. The operative must wear protective gloves and eyewear for this operation.

2. Use of the BOSST X-POT XP+ Schematic (Page 10) is required to follow the main part numbers.

3. Turn the power off to the BOSST X-POT XP+ unit by turning the Mains ON/OFF Power Switch (22) through 90°.

4. Check to see the power is off, the power to the Grundfos CRIE Smart E-Pump (21). The screen should be blank and off and the pump will not run.

5. Manually close the 2"" Isolating Valves (1 & 3) on the Dirty Flow into the BOSS™ X-POT XP+.

6. Manually close the 2"" Isolating Valves (8 & 11) on the Clean Return from the BOSS™ X-POT XP+.

7. Manually open the 2"" Isolating Valve (12). This will open the BOSS™ X-POT XP+ Vessel (4) to drain.

8. Remove the 1/2"" plug and manually open the 1/2"" Manual Vent Isolating Valve (19). This will open the BOSS X-POT XP+ Vessel (4) to atmosphere and will help the BOSS™ X-POT XP+ Vessel (4) drain quicker.

9. Un-tie and remove the top insulation cover and store in a clean and dry place.

Parts for Boss Water System XPOT XP

Access the parts list for your equipment in MaintainX.

Mains On/Off Power Switch

-

Magnet Grate 13 Magnets

-

Isolating Valve

-

Isolating Valve

-

Grundfos CRIE

-

Mains On/Off Power Switch

-

Magnet Grate 13 Magnets

-

Isolating Valve

-

Isolating Valve

-

Grundfos CRIE

-

Mains On/Off Power Switch

-

Magnet Grate 13 Magnets

-

Isolating Valve

-

Isolating Valve

-

Grundfos CRIE

-

Unlock efficiency

with MaintainX CoPilot

MaintainX CoPilot is your expert colleague, on call 24/7, helping your team find the answers they need to keep equipment running.

Reduce Unplanned Downtime

Ensure your team follows consistent procedures to minimize equipment failures and costly delays.

Maximize Asset Availability

Keep your assets running longer and more reliably, with standardized maintenance workflows from OEM manuals.

Lower Maintenance Costs

Turn any technician into an expert to streamline operations, maintain more assets, and reduce overall costs.

Thousands of companies manage their assets with MaintainX