TEST Chemtech 1 + 2 Terpene Cleanse PM (Monthly)

Once a month, run a carboy of collected terpenes through the Chemtech 2 to remove residue that isn't easily soluble in water or ethanol. This cleaning is essential to maintain proper separation in distillation in order to get a light color. Perform an ethanol/water/ethanol cleaning as usual, run the terpenes, finish with another ethanol/water/ethanol cleaning.

Use ethanol rinse parameters for the terpenes.

TEST Chemtech 1 + 2 Terpene Cleanse PM (Monthly)

Once a month, run a carboy of collected terpenes through the Chemtech 2 to remove residue that isn't easily soluble in water or ethanol. This cleaning is essential to maintain proper separation in distillation in order to get a light color. Perform an ethanol/water/ethanol cleaning as usual, run the terpenes, finish with another ethanol/water/ethanol cleaning.

Use ethanol rinse parameters for the terpenes.

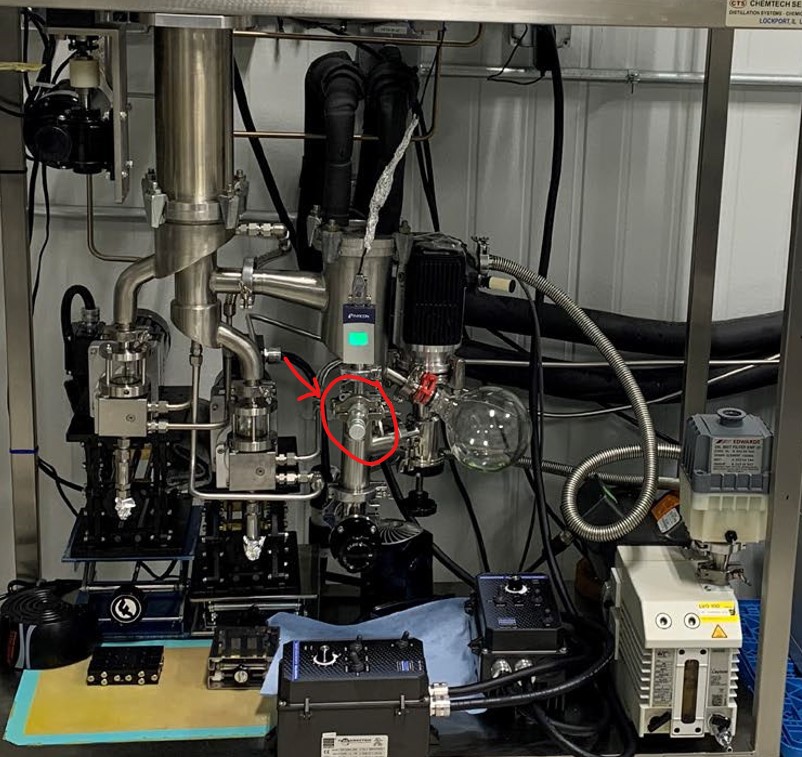

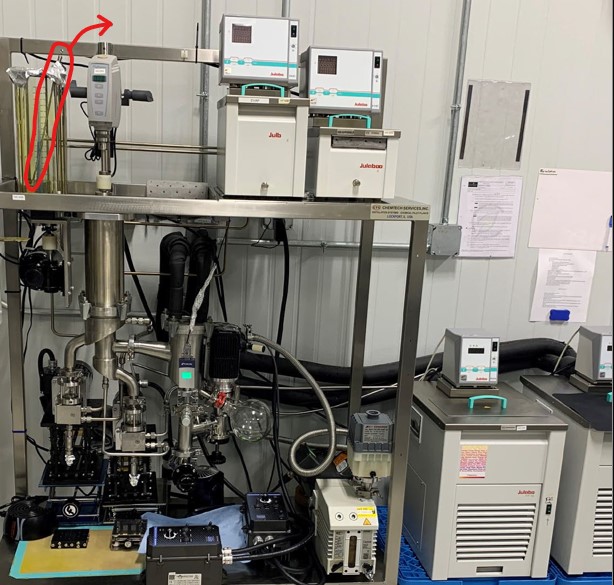

ChemTech 1 Dual Stage -Visual Inspection Procedure - Step 1

Monthly Check in Identifying Out of Spec Equipment

Warnings and Hazards

"I understand that this procedure has risks outlined below. By checking these risk boxes I understand the risks involved, how to avoid, and how to react/remedy scenarios that may occur."

Sign Here

Click here to sign

Start Up Inspection Check

Start Up system to validate visual parameters

Start Up

Inspection Check

Follow this procedure for visual validation checks

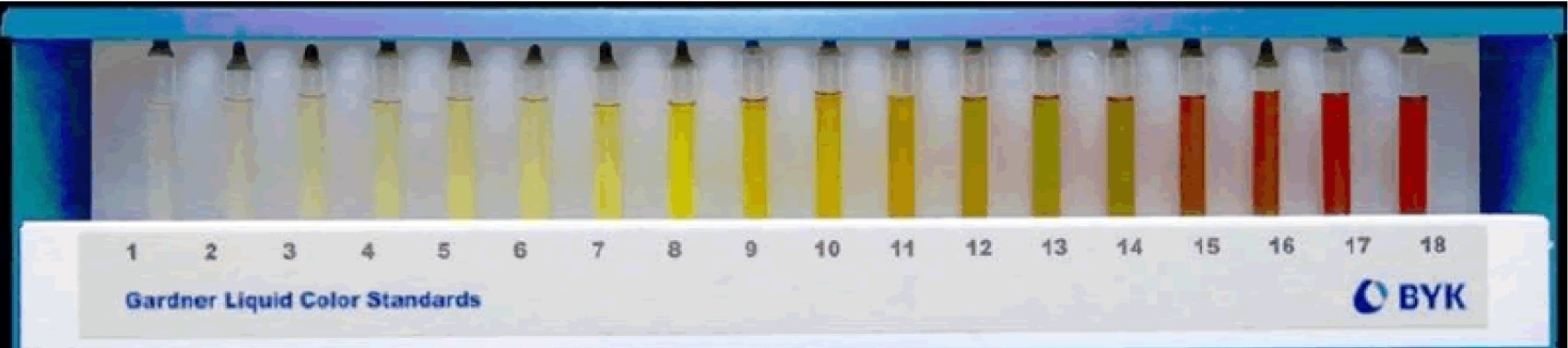

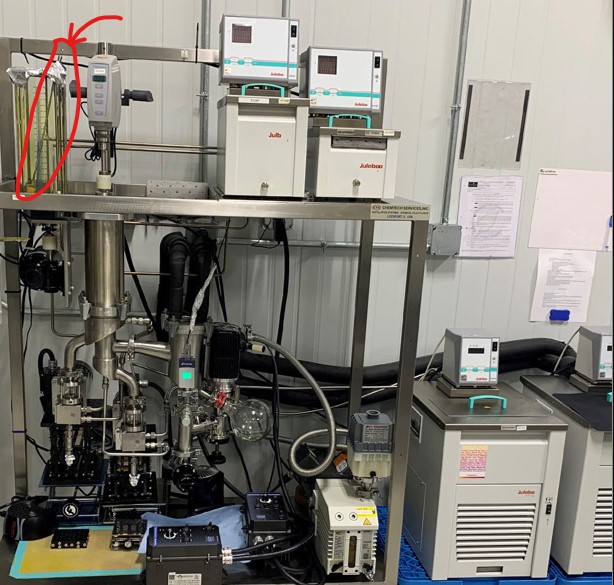

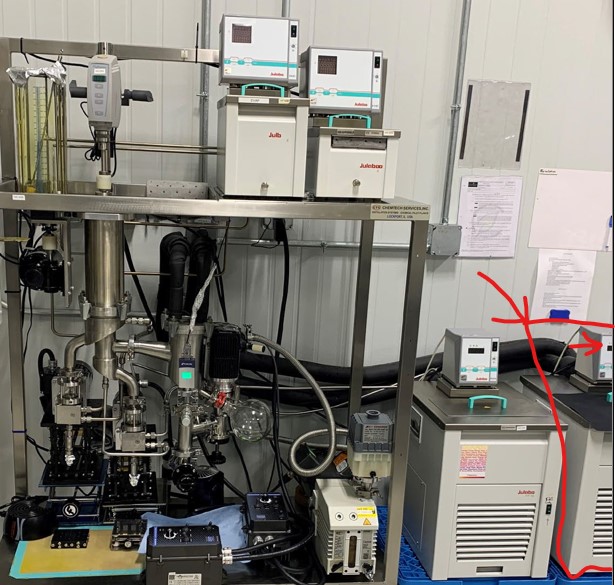

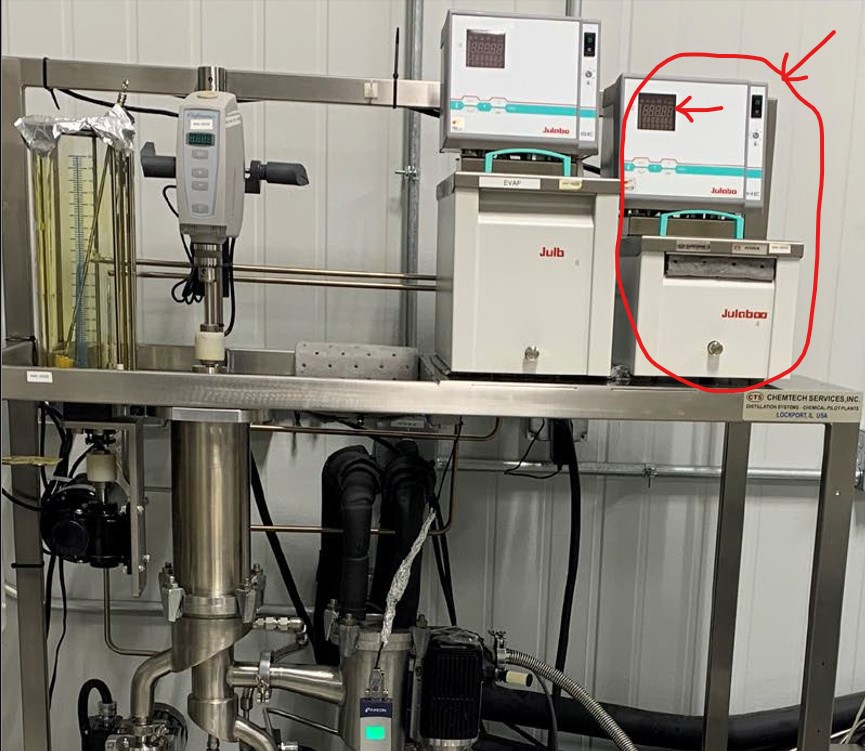

Hot Oil Circulator Fluids ( COLOR IS BELOW 12 ON GARDNER SCALE )

Condenser Fluid ( COLOR IS BELOW 7 ON GARDNER SCALE )

Cold Trap Fluid ( BATH IS NOT CLOUDY AND CONDENSATION IS NOT MAKING IT INTO BATH )

Vacuum Pump Oil ( COLOR IS BELOW 12 ON GARDNER SCALE )

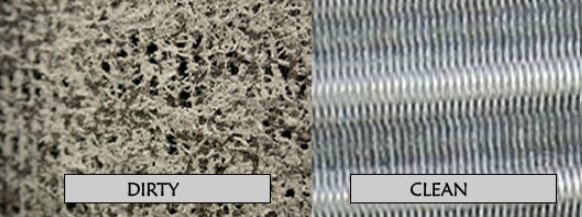

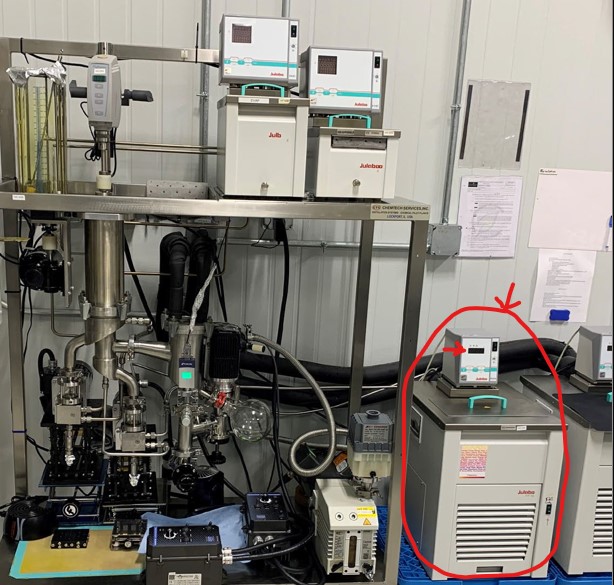

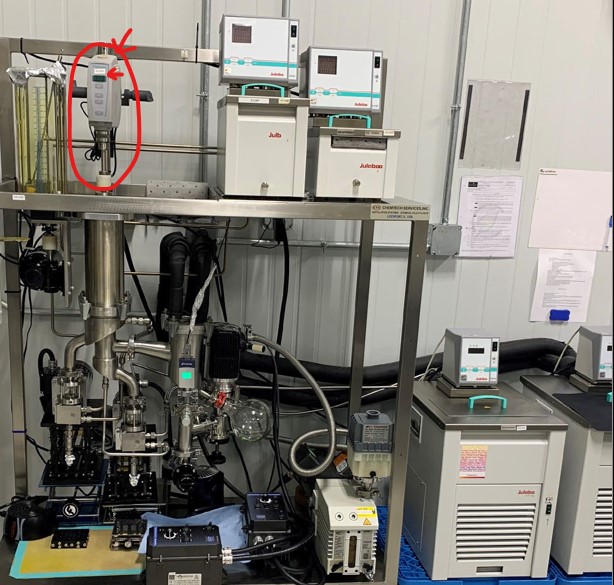

Circulators ( NO DUST OR BUILD UP ON GRILLS OR HEADS )

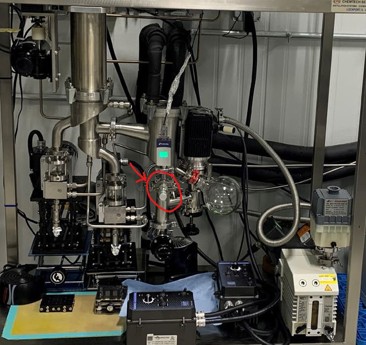

Ensure turbo pump isolation valve is set to the closed position by turning clockwise and that the turbo pump is off.

Ensure the bleed valve is opened, the vacuum valve is open, and system is otherwise vacuum sealed. Note the bleed valve should be opened as to not over pressurize the system.

Ensure Stopper in inserted to feed port properly.

Set cold trap circulator to its lowest possible set point and turn it on. ( Ensure that the cold trap reaches at least -40°C before moving on to the next step.) (> -40°C Fail : > -45°C Flag )

Meter name

Unit

if the answer is "> -40 "

Hit Fail

if the answer is "> -45 "

Hit Flag

Set feed and residue heating bath to 100 - 110°C and turn on.

Set Evaporator to 160 -163°C and turn on. Note wiper motor will need to be turned on to low rpm of 100 before the Evap bath temp reaches 100°C but after it reaches 50°C. This will avoid damage to wipers.

Start the wiper basket drive motor before the evaporator temperature reaches 100°C and set it to 100.

Set condenser bath to 35°C and turn on. ( Condenser reaches 35°C)

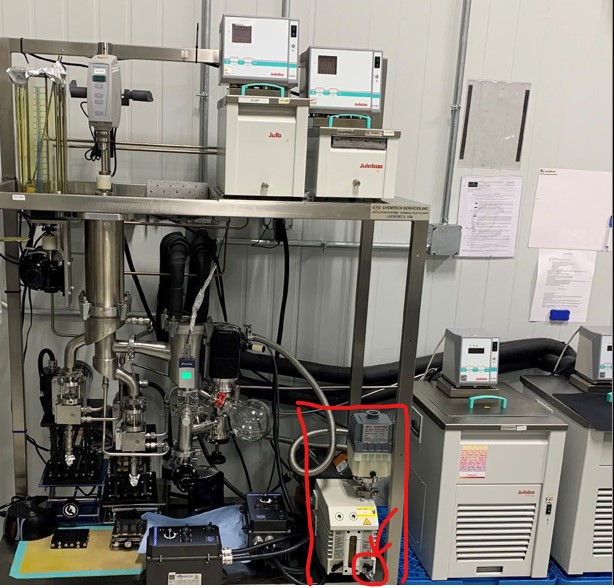

Start the rotary vane pump. (Ensure the gas ballast valve is closed.)

All Temps Reached: Feed/Residue:100 - 110°C, Condenser: 35°C, Cold trap: -45°C

Vacuum level reaches 5E-1 Torr or lower. ( >5E-1 Torr Flag : >6E-1 Torr Fail )

Meter name

Unit

if the answer is "> 0.5 "

Hit Flag

if the answer is "> 0.6 "

Hit Fail

Signature

I have completed this inspection.

Lead Operator

Click here to sign

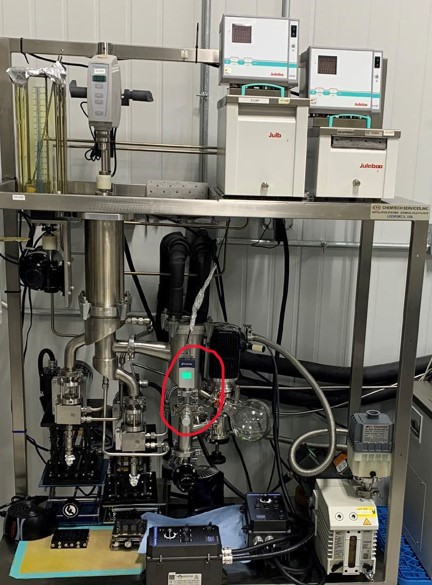

ChemTech 2 Visual Inspection Procedure - Step 2

Monthly Check in Identifying Out of Spec Equipment

Warnings and Hazards

"I understand that this procedure has risks outlined below. By checking these risk boxes I understand the risks involved, how to avoid, and how to react/remedy scenarios that may occur."

Sign Here

Click here to sign

Start Up Inspection Check

Start Up system to validate visual parameters

Start Up

Inspection Check

Follow this procedure for visual validation checks

Hot Oil Circulator Fluids ( COLOR IS BELOW 12 ON GARDNER SCALE )

Condenser Fluid ( COLOR IS BELOW 7 ON GARDNER SCALE )

Cold Trap Fluid ( BATH IS NOT CLOUDY AND CONDENSATION IS NOT MAKING IT INTO BATH )

Vacuum Pump Oil ( COLOR IS BELOW 12 ON GARDNER SCALE )

Circulators ( NO DUST OR BUILD UP ON GRILLS OR HEADS )

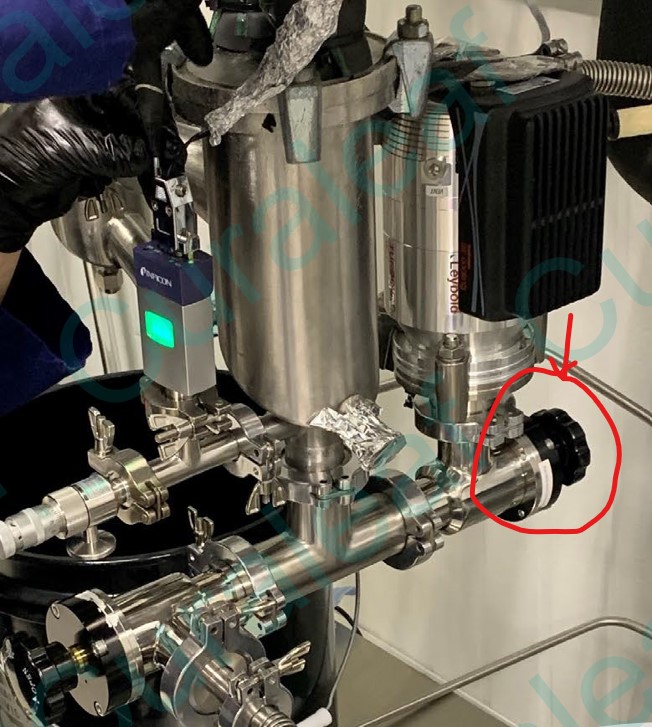

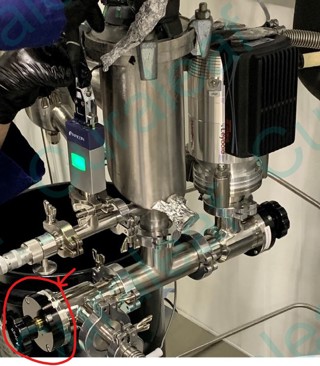

Ensure turbo pump isolation valve is set to the closed position by turning clockwise and that the turbo pump is off.

Ensure the bleed valve is open, primary vacuum valve is completely open, and system is otherwise vacuum sealed. Note the bleed valve will be closed in a later step, being open now will not allow the system to over pressurize.

Set cold trap circulator to its lowest possible set point and turn it on. ( Ensure that the cold trap reaches at least -40°C before moving on to the next step.) (< -40°C Fail : < -45°C Flag )

Meter name

Unit

if the answer is "> -40 "

Hit Fail

if the answer is "> -45 "

Hit Flag

Set evaporator heating bath to 180°C (+/- 5°C depending on distillate color and ratio).

Start the wiper basket drive motor before the evaporator temperature reaches 100°C and set it to 100.

Set condenser bath to 100°C and turn on. ( Condenser reaches 100°C)

Set feed and residue heating bath to 120°C and turn on.

Ensure feed and residue heating bath has reached 120°C. Close the bleed valve.

Start the rotary vane pump. (Ensure the gas ballast valve is closed.)

Vacuum level reaches 5E-1 Torr. ( >5E-1 Flag : >6E-1 Torr Fail )

Meter name

Unit

if the answer is "> 0.5 "

Hit Flag

if the answer is "> 0.6 "

Hit Fail

All Temps Reached: Feed/Residue:120°C, Evaporator: 180 - 185°C, Condenser: 100°C, Cold trap: -45°C

Once vacuum level reaches 4 - 5E-1 Torr, turn on the turbo pump and wait for pump to get to speed (solid green light). Once at desired speed, simultaneously close the bleed valve and open the turbo pump isolation valve. )

Signature

I have completed this inspection.

Lead Operator

Click here to sign

ChemTech 1 Dual Stage- ChemTech Terpene Cleanse Procedure - Step 3

Once a month, run a carboy of collected terpenes through the Chemtech to remove residue that isn't easily soluble in water or ethanol. This cleaning is essential to maintain proper separation in distillation in order to get a light color. Perform an ethanol/water/ethanol cleaning as usual, run the terpenes, finish with another ethanol/water/ethanol cleaning. Use ethanol rinse parameters for the terpenes.

Warnings and Hazards

"I understand that this procedure has risks outlined below. By checking these risk boxes I understand the risks involved, how to avoid, and how to react/remedy scenarios that may occur."

Sign Here

Click here to sign

Start Up

Preform a cleaning procedure prior to PM

Start Up

SOP_MFG-005 ( Click File Below )

Operator Lead

Click here to sign

Inspection Check + PM

Follow this procedure for visual validation checks prior to pouring terpenes into fill tank

System Start - Up Check ( SOP-MFG-005 7.0 PROCEDURE )

Ensure turbo pump isolation valve is set to the closed position by turning clockwise and that the turbo pump is off.

Ensure the bleed valve is open and the main vacuum pump isolation valve is open. Note the bleed valve will be closed in a later step, being open now will not allow the system to over pressurize.

Ensure Stopper in inserted to feed port properly.

Set cold trap circulator to its lowest possible set point and turn it on. ( Ensure that the cold trap reaches at least -40°C before moving on to the next step.) (< -40°C Fail : < -45°C Flag )

Set feed and residue heating bath to 100 - 110°C and turn on.

Set Evaporator to 160 -163°C and turn on. Note wiper motor will need to be turned on to low rpm of 100 before the Evap bath temp reaches 100°C but after it reaches 50°C. This will avoid damage to wipers.

Set condenser bath to 35°C and turn on. ( Condenser reaches 35°C )

Ensure feed and residue heating bath has reached 120°C. Close the bleed valve.

Start the rotary vane pump. (Ensure the gas ballast valve is closed.)

Pour terpene oil to be distilled into the feed reservoir.

Ensure feed and residue heating bath has reached 100°C.

Vacuum level reached 5E-1 Torr. ( >5E-1 Torr Flag : >6E-1 Torr Fail )

All Temps Reached: Feed/Residue:100 - 110°C, Evaporator: 160 - 163°C, Condenser: 35°C, Cold trap: -45°C

Pull out the feed plug. ( Adjust Vacuum Level to [ 7E-1 - 8E-1 ] )

Set the wiper to rotation to 400 rpm and run at a 40-45% feed rate. Start feed motor and further adjust Vacuum Level to maintain [ 7E-1 - 8E-1 ] )

Continue distilling until all the feed material has been distilled. Insert stopper into inlet of the pump at the bottom of the feed vessel. ( ** If the feed reservoir becomes empty without inserting the stopper, vacuum will be broken, and the vacuum pump can be damaged. ( To prevent vacuum loss, monitor the feed oil level until it gets to the bottom, then as the last of the oil drains into the feed pump, If vacuum begins to suck air into the pump inlet, simply insert the stopper to prevent total vacuum lo

Once feed vessel has been plugged continue distilling for approx. 15 mins to allow material in feed transfer and evap column to fully discharge. Once fully discharged ensure Eco Pump transfering to ChemTech 2 is run for an additional 5 minutes to all material in transfer to drain to ChemTech as much as possible. Some material will still be present in transfer line. Once transfer is complete stop Eco Pump via control box and lower temp on Feed/Residue heating bath to 45°C. Allow feed bath to cool before proc

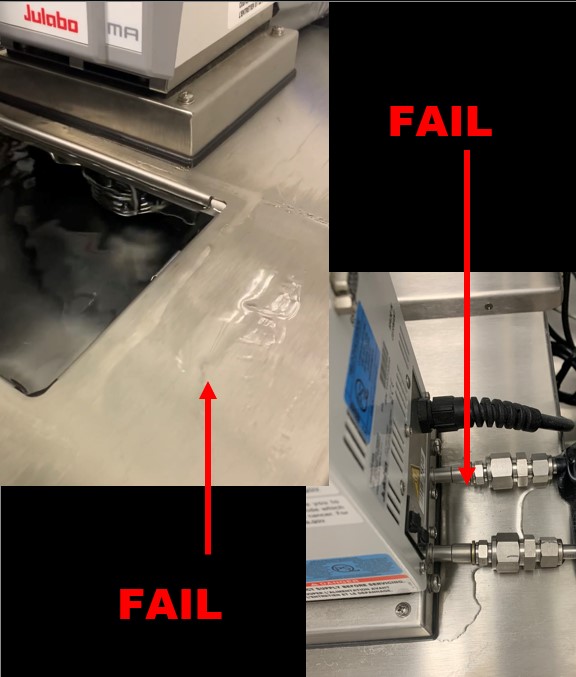

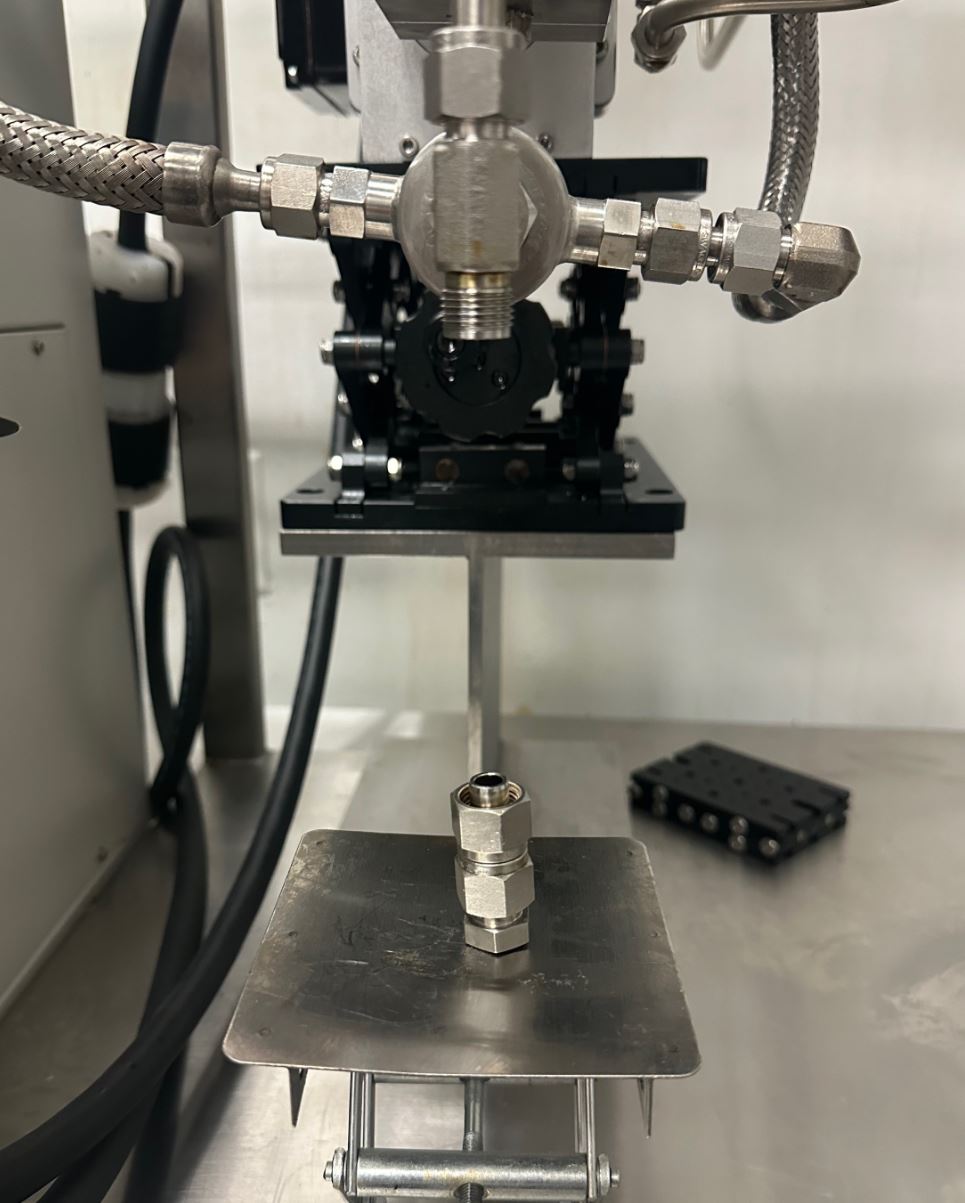

Once temperature of transfer line has dropped to set point place collection container under transfer bleed fitting. Using causing remove transfer bleed fitting and allow transfer line to full drain.

Once transfer line has fully discharged return fitting into position. Tighten fitting to maintain seal but note overtightening will shorten the life of fitting.

If the bell jars need to be emptied, the normal shutdown procedure must first be executed. (See Section 7.5. Shut Down) (**Never attempt to remove the glass discharge vessels when the system is under vacuum.**)

Change Vacuum Pump Oil

Change Vacuum Pump Oil Complete

Signature

I have completed this procedure

Operator Lead

Click here to sign

ChemTech 2 Dual Stage- ChemTech Cleanse Procedure - Step 4

Once a month, run a carboy of collected terpenes through the Chemtech to remove residue that isn't easily soluble in water or ethanol. This cleaning is essential to maintain proper separation in distillation in order to get a light color. Perform an ethanol/water/ethanol cleaning as usual, run the terpenes, finish with another ethanol/water/ethanol cleaning. Use ethanol rinse parameters for the terpenes.

Warnings and Hazards

"I understand that this procedure has risks outlined below. By checking these risk boxes I understand the risks involved, how to avoid, and how to react/remedy scenarios that may occur."

Sign Here

Click here to sign

Start Up

Preform a cleaning procedure prior to PM

Start Up

SOP_MFG-005 ( Click File Below )

Operator Lead

Click here to sign

Inspection Check + PM

Follow this procedure for visual validation checks prior to pouring terpenes into fill tank

System Start - Up Check ( SOP-MFG-005 7.0 PROCEDURE )

Ensure turbo pump isolation valve is set to the closed position by turning clockwise and that the turbo pump is off.

Ensure the bleed valve is open and the main vacuum pump isolation valve is open. The system is otherwise vacuum sealed. Over tightening may damage seals.

Set cold trap circulator to its lowest possible set point and turn it on. ( Ensure that the cold trap reaches at least -40°C before moving on to the next step.) (< -40°C Fail : < -45°C Flag )

Set feed and residue heating bath to 100 - 110°C and turn on.

Set Evaporator to 160 -163°C and turn on. Note wiper motor will need to be turned on to low rpm of 100 before the Evap bath temp reaches 100°C but after it reaches 50°C. This will avoid damage to wipers.

Set condenser bath to 35°C and turn on. ( Condenser reaches 35°C )

Start the rotary vane pump. (Ensure the gas ballast valve is closed.)

Ensure Stopper in inserted to feed port properly.

Pour terpene oil to be distilled into the feed reservoir.

Ensure feed and residue heating bath has reached 100°C.

Vacuum level reached 5E-1 Torr. ( >5E-1 Torr Flag : >6E-1 Torr Fail )

All Temps Reached: Feed/Residue:100 - 110°C, Evaporator: 160 - 163°C, Condenser: 35°C, Cold trap: -45°C

Pull out the feed plug. ( Adjust Vacuum Level to [ 7E-1 - 8E-1 ] )

Set the wiper to rotation to 400 rpm and run at a 40-45% feed rate. Start feed motor and further adjust Vacuum Level to maintain [ 7E-1 - 8E-1 ] )

Continue distilling until all the feed material has been distilled. Insert stopper into inlet of the pump at the bottom of the feed vessel. ( ** If the feed reservoir becomes empty without inserting the stopper, vacuum will be broken, and the vacuum pump can be damaged. ( To prevent vacuum loss, monitor the feed oil level until it gets to the bottom, then as the last of the oil drains into the feed pump, If vacuum begins to suck air into the pump inlet, simply insert the stopper to prevent total vacuum lo

If the bell jars need to be emptied, the normal shutdown procedure must first be executed. (See Section 7.5. Shut Down) (**Never attempt to remove the discharge glass vessels when the system is under vacuum.**)

Change Vacuum Pump Oil

Change Vacuum Pump Oil Complete

Follow to Step 5 + 6. ( By checking this box you indicate the skid is ready for Step 5+6 ) )

Signature

I have completed this procedure

Operator Lead

Click here to sign

ChemTech (OEM) Water/EtOH Cleaning Procedure - Step 5 + 6

Clean procedure based on usage and L of oil distilled. A cleaning run should be done weekly or monthly depending on production volumes. All non cannabis based cleaning cycles are to be done with NO vacuum. After cleaning run, change the vacuum pump oil

Warnings and Hazards

"I understand that this procedure has risks outlined below. By checking these risk boxes I understand the risks involved, how to avoid, and how to react/remedy scenarios that may occur."

Sign Here

Click here to sign

Start Up

Preform a cleaning procedure prior to PM

Start Up

Operator Lead

Click here to sign

Water/EtOH Cleaning Procedure

Follow this procedure for visual validation checks

Set Equipment to these conditions

Close both of the right-angle valves to isolate the turbo pump and the rotary vane vacuum pump from the rest of the system.

Remove the vacuum sensor and needle valve from the system before performing the cleaning cycle.

First Pass - Clean the entirety of the feed tank using the water:ethanol mix 10:90. Water should be either RO or distilled. Minimum of 500ml must be used.

Verify Equipment set points - Feed Rate: 50 Wiper Speed: 250 Feed/Residue: 50°C Evaporator: 78°C Condenser: 50°C Cold Trap: 5°C

Allow water:ethanol mix to reach set point temp then run the feed pump at a rate of 50 to remove all contaminated water/ethanol. Empty cold trap collection as needed as to not allow to over fill.

Prepare for Second Pass-Set Equipment to these conditions

Second Pass- Use 500 mL of the water. Empty cold trap collection throughout process as need as to not over fill.

Prepare for Third Pass-Set Equipment to these conditions

Third Pass- Use a minimal of 250 mL of the ethanol. Empty cold trap collection throughout process as need as to not over fill.

With discharge pump systems – once all fluid has passed through discharge pumps turn controllers to the stop position and power off.

If additional cleaning is needed, then repeat the water/ethanol cleaning cycle as many times as needed until the distillate and residue streams are flowing clean and clear ethanol/water.

**If system is equipped with discharge pumps.** This step is to maintain lubrication in gear pumps.

1.) Fill 50ml conical falcon tube can be filled with terp strip material. 2.) With the vacuum bleed port open set the discharge pump controllers to ‘reverse’ and a slow rate of 10 or less. 3.) Place the conical falcon tube at the base of one of the check valves at the exit port of the discharge pump and raise enough to submerge the tip into terp strip material. 4.) Turn on the discharge pump controller to back feed terp strip material until material is seen int the sight glass. Stop the pump via the pump controller. 5.) Switch direction from ‘reverse’ to ‘forward’ and start the pump again discharging material back into the conical falcon tube. Run until no material is seen dripping and stop pump via controller and power pump down. This will keep the gear pump lubricated and prevent excessive wear. 6.) Repeat steps 7.6.10 for other discharge pump if necessary. NOTE: The next time the system is started up for a THC distillate pass, 1-3 cups will need to be collected from the distillate side of the discharge pump and redeposited into the feed tank. This will remove any of the terp strip used as lubrication.

Drying

Set Equipment to these conditions

The system is in hot state with no feed at the set conditions above.

After allowing the warmer temperatures to dry the system at atmosphere for 1 hour, return vacuum gauge and needle valve bleed port to proper position closing the needle valve bleed port.

Open the main vacuum isolation valve and pull vacuum using only the main rotary vane vacuum pump for 1 hour to fully dry the system out. Keep the turbo pump isolated (closed) from the system for the vacuum drying portion. Change the vacuum pump oil after finishing the drying process.

Signature

I have completed this inpection

Operator Lead

Click here to sign

Source: Curaleaf Gold Standard (Community Member)