Eyewash & Safety Showers Inspection (Weekly) - Houston

A Weekly Eyewash & Safety Showers Inspection is a regular examination of your emergency eyewash and safety showers. This process includes weekly activation of the equipment to confirm it’s working correctly and conducting inspections. Regular use of the units ensures they are functioning as expected, assists in maintaining the units clutter-free, and aids in preventing bacterial growth within the plumbing lines, which could lead to eye infections.

Eyewash & Safety Showers Inspection (Weekly) - Houston

A Weekly Eyewash & Safety Showers Inspection is a regular examination of your emergency eyewash and safety showers. This process includes weekly activation of the equipment to confirm it’s working correctly and conducting inspections. Regular use of the units ensures they are functioning as expected, assists in maintaining the units clutter-free, and aids in preventing bacterial growth within the plumbing lines, which could lead to eye infections.

1. Job Hazard Analysis

Activity/Task/Process

Department

Machine # (if applicable)

Date

Prepared by

Crew Names

Reviewed By

Overall Risk Assessment Score (RAS) (Use Highest Code)

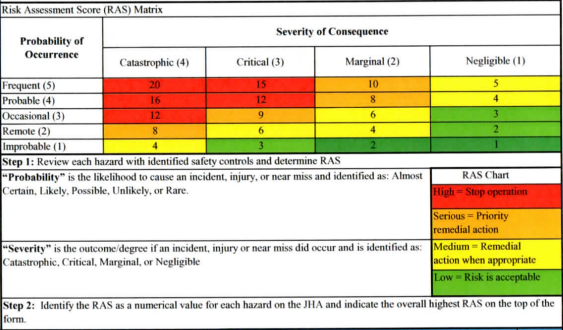

Risk Assessment Score (RAS) Matrix

Job Description

Job Step #1

Job Step

Hazards

Controls

RAS

Job Step #2

Job Step

Hazards

Controls

RAS

Job Step #3

Job Step

Hazards

Controls

RAS

Job Step #4

Job Step

Hazards

Controls

RAS

Job Step #5

Job Step

Hazards

Controls

RAS

Job Step #6

Job Step

Hazards

Controls

RAS

REQUIRED Personal Proctective Equipment

Date of Inspection

Inspector Name

Inspection Items

The area around and the path to the eyewash is not obstructed.

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Verify nozzle caps are in place and the nozzles, nozzle caps, and bowl are clean and sanitary.

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Push hands-free valve to full open position. Water must flow within 1 second. Run minimum 60 seconds

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Verify that nozzle caps come off when the eyewash is activated and water is flowing.

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Verify water continues to flow until manually turned off and can be used hand-free by pushing water valve activator..

Comments

Please specify defects which specific eye wash or safety shower has a defect.

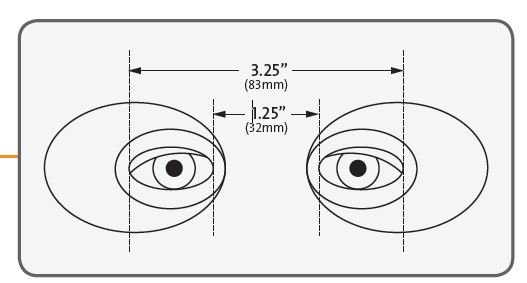

Look at the water flow pattern. It should provide a non-injurious flow from both nozzle streams.

Comments

Please specify defects which specific eye wash or safety shower has a defect.

The water should flow from both streams and rise to an equal height in a pattern that will flush both eyes simultaneously.

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Water flow covers area shown in test gauge, maximum 8” above spray heads, minimum 33" above the floor.

Test Gauge

Add or drag pictures

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Continue to run eyewash and flush until water is clear.

Comments

Please specify defects which specific eye wash or safety shower has a defect.

Inspection Complete

Inspector Signature

Click here to sign

Source: Eye Wash 1 (Community Member)