Six-monthly Cleaning and Maintenance Procedure AmbaFlex Spiral Conveyor

Spiral Conveyor Maintenance involves the regular checking and upkeep of the various components of the conveyor system to ensure they are functioning correctly. This includes the shaftless spiral, liners, troughs, and the direct drive. The controls must be designed to prevent unintended accumulation and prevent product back-ups in the spiral.

Six-monthly Cleaning and Maintenance Procedure AmbaFlex Spiral Conveyor

Spiral Conveyor Maintenance involves the regular checking and upkeep of the various components of the conveyor system to ensure they are functioning correctly. This includes the shaftless spiral, liners, troughs, and the direct drive. The controls must be designed to prevent unintended accumulation and prevent product back-ups in the spiral.

Six-monthly Cleaning and Maintenance Procedure

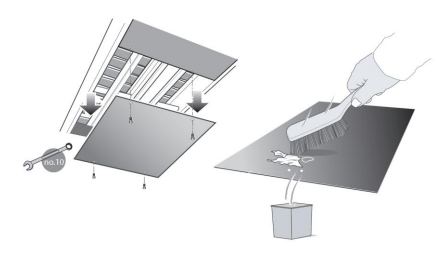

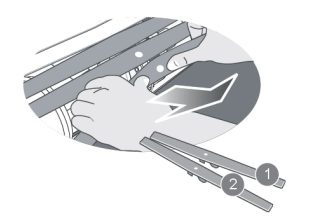

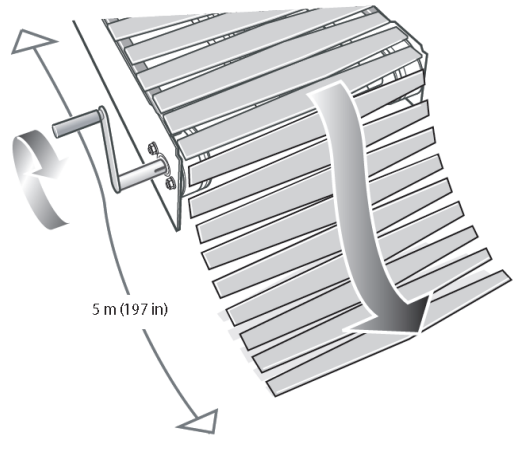

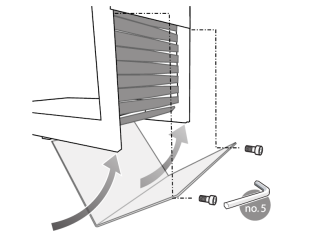

Remove the belts of the machine in the following sequence:

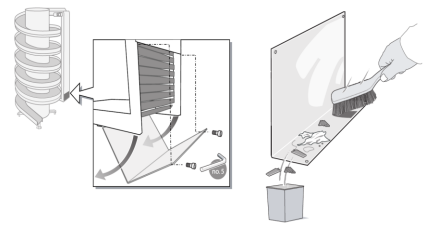

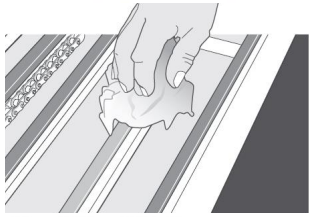

Check that there is no contamination left on the machine. Otherwise resume with procedure no 5.

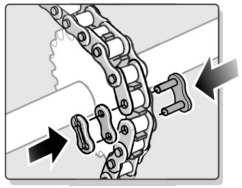

Replace the chain in the machine in the following sequence:

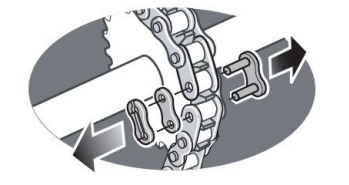

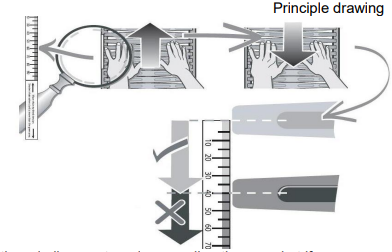

Check the chain tension. Remove a link once the chain has an over-length of 38.5 mm.

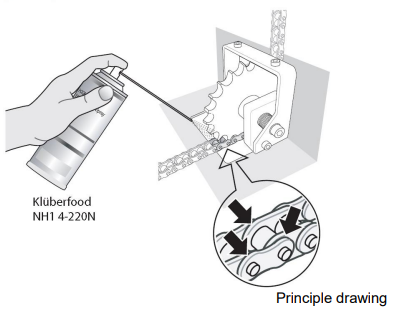

Check the sprocket for worn teeth and alignment, replace or align the sprocket if necessary. Misalignment of the sprocket can result in permanent wear or can result in the chain coming off the sprocket, which can cause a serious blockage.

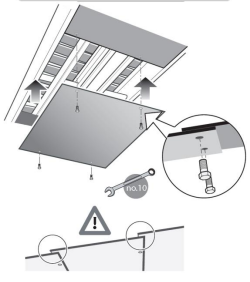

Check the side guides for dents, damage, and alignment. Replace the guides if they damage the products. Contact the supplier about this.

Check for missing or damaged O-belts on the transition rollers and reversing rollers. Replace if necessary.

Check the transition roller for imbalance and smooth running of the bearings.

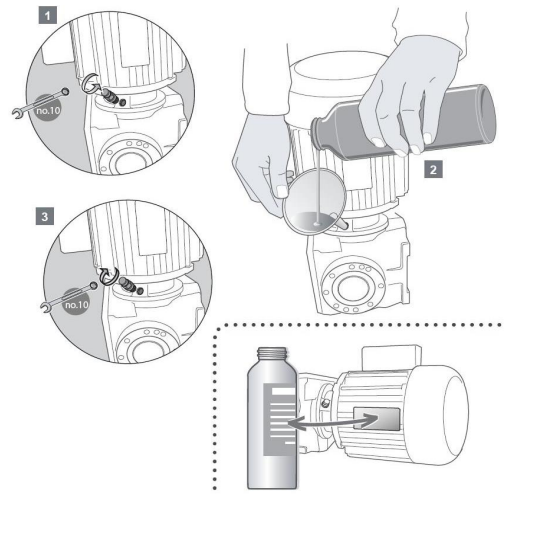

Check the drive for oil leaks and noise. Repair or clean if necessary. See the troubleshooting list.

Check if the motor reductor is securely fastened to the machine, tighten the bolts if necessary. Vibrations in the drive can loosen the conveyor plates. Incorrect alignment can bend the shaft and/or can result in the chain coming off the sprocket.

Check the motor reductor oil level, top up if necessary. Refer to the manufacturer’s motor-reductor specifications..

Sign off on the preventative maintenance

Click here to sign

Source: Groveport - Radial (Community Member)