Shake & Sundae Carpigiani Preventative Maintenance

The Shake & Sundae Carpigiani Preventative Maintenance Form decreases equipment downtime and the number of major repairs are reduced. You will get better conservation of your asset and increased its life expectancy, thereby eliminating premature replacement of your equipment.

Shake & Sundae Carpigiani Preventative Maintenance

The Shake & Sundae Carpigiani Preventative Maintenance Form decreases equipment downtime and the number of major repairs are reduced. You will get better conservation of your asset and increased its life expectancy, thereby eliminating premature replacement of your equipment.

During daily, weekly and fortnightly cleaning operations, check carefully the integrity of parts subject to wear: if they appear worn, torn or not totally functional replace them.

The manufacturer offers programmed maintenance plans that include the periodical replacement of parts subject to wear.

SHAKE SIDE

PUMP

Integrity of O-ring and overflow valves

Dry smoothness of gears in their seats.

DISPENSING DOOR

Check O-ring integrity, check smoothness of piston.

Check syrup duck bill valves

TANK MIXER

Check if it rotates freely.

CYLINDER BEATER

Check if beater idler and scraper blade show dents and check their integrity.

Check integrity of beater seal (# 28).

Check that the wear on the bushing on the beater idler is no more than 2 mm, as indicated by the marking on the bushing itself. If there is more than 2 mm wear, it is necessary to replace the beater idler

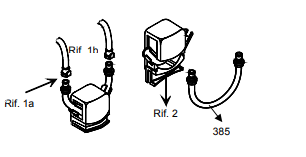

PERISTALTIC PUMP TUBE (# 385)

Check the integrity

PUMP

Integrity of O-ring and overflow valves.

Dry smoothness of gears in their seats.

DISPENSING LID

Check integrity of O-ring, check smoothness of piston

CYLINDER BEATER

Check if scraper blades show dents and crack.

Check if end-pusher and beater idler show dents and check their integrity.

Check integrity of beater seal (# 28).

PERIODICAL CHECK-UP AND MAINTENANCE

PERISTALTIC PUMP TUBE REPLACEMENT INSTRUCTION

PUMP TUBE REMOVAL

Pump Tube Installation

Source: Carpigiani (www.manualslib.com)