Doosan D30S-5 Pneumatic Forklift 50 - 100 Service Hours

The Doosan D30S-5 Pneumatic Forklift 50 - 100 Service Hours ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Doosan D30S-5 Pneumatic Forklift 50 - 100 Service Hours

The Doosan D30S-5 Pneumatic Forklift 50 - 100 Service Hours ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Engine Oil & Filter (Diesel Engine Only) - Change

The engine oil in a new engine becomes contaminated from the initial break-in of internal parts. It is very important that the initial oil and filter change is performed as scheduled

NOTE: The oil drain plug may be in another location if an optional oil pan is used..

Drain the engine oil as follows:

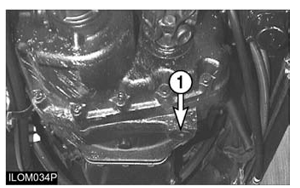

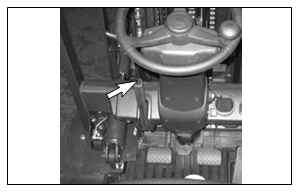

Figure 5-1

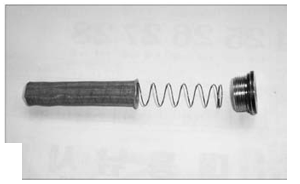

Remove the engine oil filter as follows:

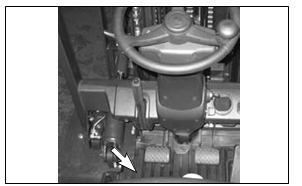

Figure 5-2

WARNING: NEVER overfill the engine with engine oil. ALWAYS keep the oil level between the upper and lower lines on the oil cap/dipstick.

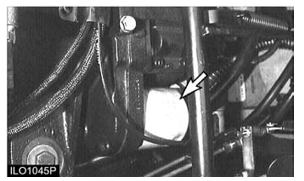

Figure 5-3

NOTICE : Servicing of the engine oil and oil filter element will largely affect the engine performance as well as the engine life. Engine oil and filter element must be changed after the first 50 hours.

Transmission Oil, Oil Filter & Strainer - Check, Clean, Change

WARNING: Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Park the lift truck level, with the forks lowered, parking brake engaged, direction control lever in NEUTRAL and the engine stopped.

Drive Axle Oil - Change

Park the lift truck on a level surface. Apply the parking brake. Place the directional control lever in NEUTRAL and stop the engine.

NOTE: Tighten the dipstick plug fully not to allow foreign parts(rain, water etc) to enter into drive axle.

Parking Brake - Test, Adjust

Parking Brake Testing

NOTICE OSHA requires the parking brake to hold the lift truck, with capacity load, on a 15% grade. Testing requires a test load equal to the capacity of the truck and a 15% grade. If the maximum grade in the workplace is less than its capacity, use the Pa

WARNING: To prevent personal injury, the operator MUST be ready to use the service brake if the parking brake is not adjusted correctly and the lift truck starts to move.

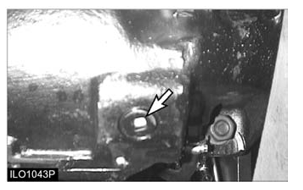

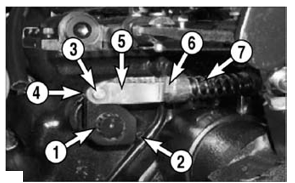

Parking Brake Adjusting

NOTICE :Turn the adjustment screw (6) clockwise to tighten. Turning the screw (6) too far counterclockwise could allow parts to fall into the bottom of the transmission. The transmission would than require disassembly to remove the parts.

Source: Doosan