Doosan D33S-5 Pneumatic Forklift FORMS (Daily Maintenance)

The Doosan D33S-5 Pneumatic Forklift FORMS (Daily Maintenance) ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Doosan D33S-5 Pneumatic Forklift FORMS (Daily Maintenance)

The Doosan D33S-5 Pneumatic Forklift FORMS (Daily Maintenance) ensures the quality performance of your forklift by identifying parts to replace/repair. Ensure the lifespan of your is preserved.

Inspect Engine for Fluid Leaks

Engine Oil Level - Check

WARNING:Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Gasoline and LP Engines

Diesel Engines

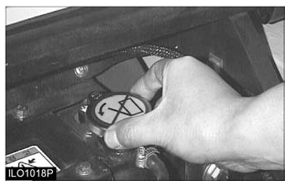

Coolant Level – Check

WARNING: At operating temperature, the engine coolant is hot and under pressure. Steam can cause personal injury. Check the coolant level only after the engine has been stopped and the filter cap is cool enough to touch with your bare hand.

Remove the filter cap slowly to relieve pressure. Cooling system conditioner contains alkali. Avoid contact with the skin and eyes to prevent personal

4TNV98 Diesel Engine

WARNING:Pressure air can cause personal injury. When using pressure air for cleaning, wear a protective face shield, protective clothing and protective shoes. Maximum air pressure must be less than 205 kPa (30 psi) for cleaning purposes.

Air Cleaner Indicator-Check

Checking Service Indicator

NOTE: Service the element more frequently, as required, in severe dust or lint conditions. Also, service it more frequently where the operator is required to wear a respirator.

Walk-Around Inspection - Inspect

For maximum service life of the lift truck, make a thorough walk-around inspection. Look around and under the truck for such items as loose or missing bolts, debris or dirt buildup, fuel, oil or coolant leaks and cut or gouged tires.

Have any repairs made and debris removed, as needed.

Inspect the forks.

Mast Channels – Lubricate

The channels on the roller-type mast require a break-in period. Apply a light film of lubricant on the channels where the rollers ride. This will prevent metal peel until the rollers set a pattern.

Transmission Oil Level – Check

WARNING: Hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin.

Parking Brake - Inspect

Inspection from Operator's Seat, Engine OFF

Inspection from Operator's Seat, Engine ON

PARKING BRAKE SWITCH

Parking Brake

NOTE: The parking brake is required to be adjusted to hold the lift truck with capacity load on a 15% grade. If there is a 15% grade in your workplace, engage a capacity load and drive over to the grade.

If the maximum grade in your workplace is less than 15% or if the maximum load carried by the lift truck is less than the lift truck's load capacity, pick up the maximum load and drive to the steepest grade in your workplace.

Source: Doosan