2019 CLARK S20C IC Cushion 50-250 hours PM

The 2019 CLARK S20C IC Cushion 50-250 hours preventive maintenance form has the complete list to check the truck visually and inspect its components. The form has both a list of parts to inspect and instructions on how to do it.

2019 CLARK S20C IC Cushion 50-250 hours PM

The 2019 CLARK S20C IC Cushion 50-250 hours preventive maintenance form has the complete list to check the truck visually and inspect its components. The form has both a list of parts to inspect and instructions on how to do it.

Check truck visually and inspect components.

Test drive truck/check functional performance.

Overhead Guard

Load Handling Components

Inspect the:

Carefully check the lift chains for

Air clean truck and radiator

Check torque on critical fasteners.

Critical items include:

Drain and replace engine oil.

It is recommended to:

Engine oil at operating temperature is hot and can cause burns. Beware of splashing oil.

Replace engine oil filter.

Changing the Engine Oil and Oil Filter

Inspect / adjust fan belts.

Inspect the

Drain / flush radiator coolant.

If the level is low, add a 50/50 mixture of specified coolant and water to the correct fill level. If you have to add coolant more than once a month or if you have to add more than one litre at a time, check the coolant system for leaks.

Check engine ignition and timing.

You will start the engine to complete the functional tests, so be sure that:

Engine tune-up.

Be sure that the travel area is clear in front of the truck.

Check battery.

Inspect the battery for

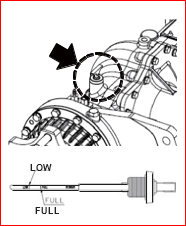

Check transmission fluid level.

Before checking

Change drive axle fluid. (cooling system not equipped) - Cooling system equipped : 2,000 hours

Check brake condition and wear.

Parking Brake

Check drive axle mounting and fasteners.

Critical items include:

Lubricate steer axle linkage.

Lubrication and inspection of truck chassis components, including :

Inspect the steering cylinder piston

Check / lubricate steer axle wheel bearings

Horn Button

Change / replace hydraulic sump oil filter and breather

Sump Tank Breather Maintenance and Inspection

Change / replace hydraulic sump fluid and oil filter.

Lubricate tilt cylinder rod ends.

Upright and Tilt Cylinder Lubrication

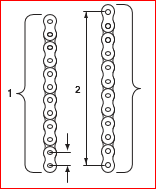

Lift Chains

Check lift chain adjustment and wear.

During the inspection, check for the following conditions:

Check / lubricate lift chains.

Lift Chain Wear and Replacement Criteria:

Source: Clark