2019 CLARK HWX 40 Walkie Pallets 50-250 Hours PM

The 2019 CLARK HWX 40 Walkie Pallets 50-250 Hours PM procedure ensures that the handling of the walkie pallet is textbook from start to finish. This procedure allows you to quickly identify the parts that need to be replaced or repaired.

2019 CLARK HWX 40 Walkie Pallets 50-250 Hours PM

The 2019 CLARK HWX 40 Walkie Pallets 50-250 Hours PM procedure ensures that the handling of the walkie pallet is textbook from start to finish. This procedure allows you to quickly identify the parts that need to be replaced or repaired.

Check truck for obvious damage and leaks

Test drive truck-Check functional performance

Before Starting To Work On Truck:

Operation of the truck to check performance must be conducted in an

Before Starting to Drive the Truck:

Before Leaving the Truck:

must be carefully and regularly inspected and maintained in a safe operating condition.

Lubricate truck

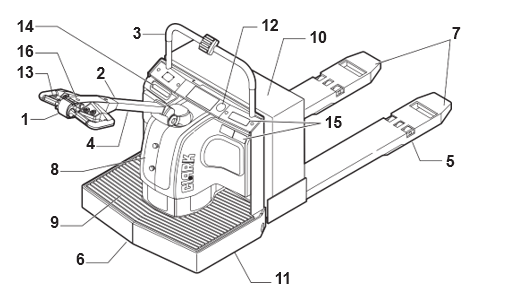

Component Location-HWX

Clean/check battery terminals, electrolyte level

IMPORTANT During cleaning, the battery vent caps must be tightly in place.

Perform battery load test

Check lift pump motor brushes

HWX Lift and Lower Controls

Source: Clark