JUNGHEINRICH EFG 550 Electric Forklifts Truck 1000 Hours/6 Months

The JUNGHEINRICH EFG 550 Electric Forklifts Truck 1000 Hours/6 Months is a semi-annual preventive maintenance form. Ensure your equipment's performance by using the complete checklist provided in this form.

JUNGHEINRICH EFG 550 Electric Forklifts Truck 1000 Hours/6 Months

The JUNGHEINRICH EFG 550 Electric Forklifts Truck 1000 Hours/6 Months is a semi-annual preventive maintenance form. Ensure your equipment's performance by using the complete checklist provided in this form.

Chassis/ Superstructure

1.1 Check all load bearing items for damage

1.2 Check screw connections

1.3 Check trailer coupling

1.4 Check overhead guard for damage and make sure it is secure

1.7 Check decals. Make sure they are present, legible and valid.

Drive:

Reversing brake (single pedal)

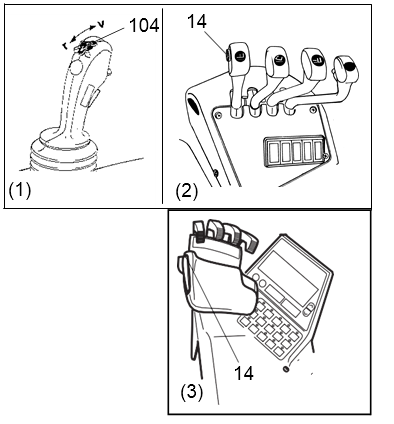

Depending on the truck model, the travel direction switch may be fitted to the

Reversing brake (twin pedal)

Wheels:

Steering:

4.1 Test operation of hydraulic components and check for leaks

Brake system:

5.2 Check brake mechanism, adjust and lubricate if necessary

There are five ways of braking

Service brake:

Coasting brake:

5.3 Check brake lines, brake connections and brake system oil level

Hydraulic System:

6.5 Test operation of hoses and check for damage

6.6 Replace filter cartridge (hydraulic oil and discharge filter)

Electrical System:

7.3 Test cable guide operation and check for damage

Hour meter

Controller over temperature

Pump motor, steering booster over temperature

Drive motor over temperature

Seat switch

Parking brake applied

Travel direction indicator o

Truck operational

Service display / UVV display

Insufficient brake fluid

WARNING

Crawl speed switch

Travel speed max. 6 km/h (adjustable)

Program selector

SET key

Operating program display

Electric motors:

Battery:

Mast:

10.2 Check lift chains for wear and adjust.

10.6 Check forks and fork carriage for wear and damage

Adjust the fork tines in such a way that both are equally distanced from the outer edge of the fork carriage and the load centre of gravity lies in the middle of the fork tines.

Demonstration

Source: Jungheinrich