Doosan D20S-5 Forklift Pneumatic Tire Lift Truck 1500 Hours/ 9 Months

The Doosan D20S-5 Forklift Pneumatic Tire Lift Truck 1500 Hours/ 9 Months procedure inspects your engine for fluid leaks, engine oil level, coolant level and also checks the air cleaner indicator. This form helps in ensuring your forklifts maintains its quality performance.

Doosan D20S-5 Forklift Pneumatic Tire Lift Truck 1500 Hours/ 9 Months

The Doosan D20S-5 Forklift Pneumatic Tire Lift Truck 1500 Hours/ 9 Months procedure inspects your engine for fluid leaks, engine oil level, coolant level and also checks the air cleaner indicator. This form helps in ensuring your forklifts maintains its quality performance.

Inspect Ignition System (LP, Gasoline & Dual Fuel Engines Only)

G420F(E) Engine

G424F(E) Engine

G424I(E) Engine

G430FE Engine

Replace Spark Plugs (G424F(E) LP, Dual Fuel Engine / G430FE Engine Only)

WARNING:DO NOT OVERTIGHTEN THE SPARK PLUGS.

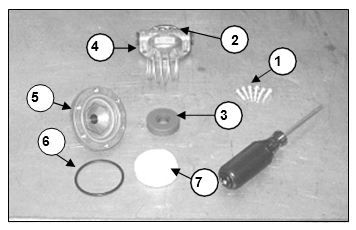

Replace LP Fuel Filter Element (LP, Dual Fuel Engine Only)

Park the lift truck in an authorized refueling area with the forks lowered, parking brake applied and the transmission in Neutral.

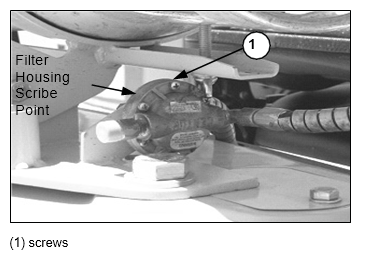

Fuel Filter (LP Engine Only) Disassembly

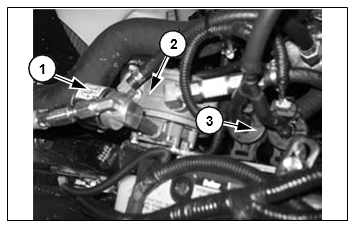

Testing Fuel Lock-off Operation (LP Engine Only)

NOTE: The length of time the engine runs on trapped fuel vapor increases with any increase in distance between the fuel lock-off and the pressure regulator/converter.

Fuel Injectors (Diesel Engine Only) – Inspect, Clean, Test

WARNING: HIGH-PRESSURE HAZARD! Avoid skin contact with the high-pressure diesel fuel spray caused by a fuel system leak such as a broken fuel injection line. High-pressure fuel can penetrate your skin and result in serious injury. If you are exposed to hi

NEVER check for a fuel leak with your hands. ALWAYS use a piece of wood or cardboard. Have your authorized Yanmar industrial engine dealer or distributor repair the damage. Failure to comply could result in death or serious injury.

Proper operation of the fuel injectors is required to obtain the optimum injection pattern for full engine performance.

The EPA / ARB requires that the fuel injectors are inspected, cleaned and tested every 1500 hours. See Testing of Fuel Injectors on Service Manual

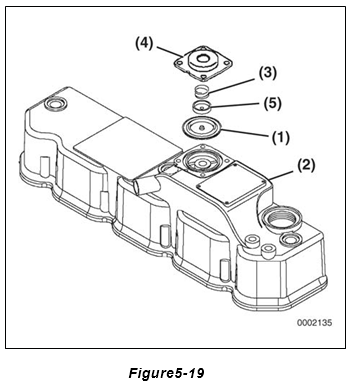

Crankcase Breather System (4TNV98 Diesel Engine Only) - Inspect

To inspect the diaphragm and spring (Figure5-19, (3)):

Failure of the diaphragm and / or spring will cause the loss of pressure control and allow an excessive amount of crankcase fumes to be routed to the intake manifold.

This could result in excessive deposits in the intake system, high engine exhaust smoke levels, excessive engine oil consumption, and / or engine run-on due to the burning of the engine oil

Source: Doosan