HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT Daily Maintenance

The HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT Daily Maintenance keeps your forklift in prime working condition. Maximize your forklifts capabilities by consistently performing maintenance.

HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT Daily Maintenance

The HYSTER 13500LB H135XL DIESEL PNEUMATIC FORKLIFT Daily Maintenance keeps your forklift in prime working condition. Maximize your forklifts capabilities by consistently performing maintenance.

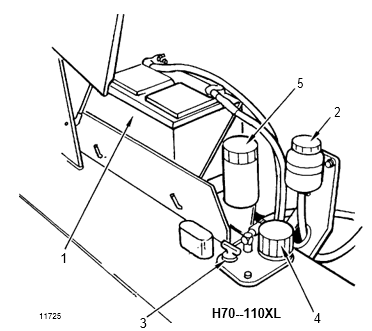

HYDRAULIC OIL H70- 110XL

WARNING: At operating temperature the hydraulic oil is HOT. Do not permit the oil to contact the skin and cause a burn.

CAUTION : Do not permit dirt to enter the hydraulic system when the oil level is checked or the filter is changed. Never operate the pump without oil in the hydraulic system. The operation of the hydraulic pump without oil will damage the pump.

Engine Oil (See FIGURE 14.)

Air Filter (See FIGURE 14.)

WARNING: Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all person- nel. Wear protective goggles or a face shield to prevent injury to the eyes.

FIGURE 13. MAINTENANCE POINTS

Oil Level, Powershift Transmission (See FIGURE 28.)

Oil Level, Oil Clutch System, H70- 110XL (See FIGURE 28.)

NOTE: The oil clutch system for the H135- 155XL (F006) lift trucks do not have a dipstick because the oil clutch uses oil from the hydraulic system.

FIGURE 28. POWERSHIFT TRANSMISSION OR OIL CLUTCH SYSTEM OIL

FUEL TANK H70- 110XL

WARNING: Stop the engine. Turn the key switch to OFF. The operator must

No smoking.

COOLING SYSTEM H70- 110XL Gasoline/LPG

Cooling System (See FIGURE 15.)

WARNING: DO NOT remove the radiator cap from the radiator when the engine is hot. When the radiator cap is re- moved, the pressure is released from the system.

FIGURE 15. AUXILIARY COOLANT RESERVOIR

WARNING: Compressed air can move particles so that they cause injury to the user or to other personnel.

Make sure that the path of the compressed air is away from all person- nel. Wear protective goggles or a face shield to prevent injury to the eyes.

BATTERY ELECTROLYTE

WARNING:The acid in the electrolyte can cause injury. If the electrolyte is spilled, use water to flush the area. Use a solution of sodium bicarbonate (soda) to make the acid neutral. Acid in the eyes must be flushed with water immediately.

Batteries generate explosive fumes. Keep the vents in the caps clean. Keep sparks or open flame away from the battery area. Do not make sparks from the battery connections. Disconnect the battery ground cable when doing maintenance.

If the battery becomes discharged and requires a boost battery to start the engine, follow these procedures carefully when connecting the jumper cables:

Check Conditions

DRIVE BELTS

Check Conditions

Check Condition and Operation

WARNING: Never work under a raised carriage or forks. Lower the carriage or use blocks and chains on the mast weld- ments and carriage so that they can not move. Make sure the moving parts are attached to a part that does not move.

Do not try to correct the alignment of the fork tips by bending the forks or adding shims. Replace damaged forks.

Never repair damaged forks by heating or welding. Forks are made of special steel using special procedures. Replace damaged forks.

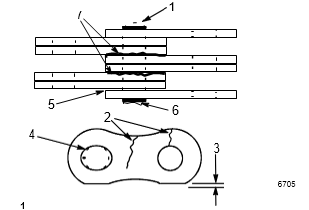

FIGURE 21. CHECK THE FORKS

FORK TIP ALIGNMENT

FIGURE 22. CHECK THE LIFT CHAINS

Check For Leaks

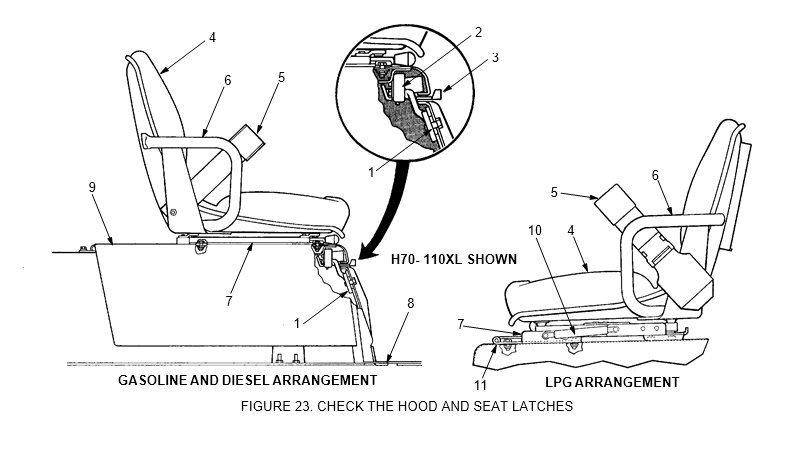

FIGURE 23. CHECK THE HOOD AND SEAT LATCHES

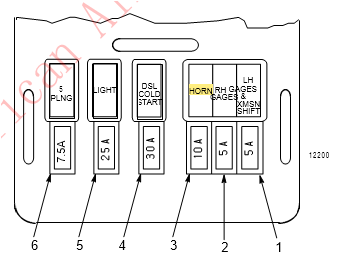

HORN, GAUGES, LIGHTS, ALARMS

FIGURE 25. FUSES

Check:

STEERING

SERVICE BRAKES

WARNING: Loss of fluid from the brake fluid reservoir indicates a leak. Repair the brake system before using the lift truck. Replace the brake fluid in the system if there is dirt, water or oil in the system.

The lift truck has a brake booster that receives power from the hydraulic system. The brake pedal can be hard to push when the engine is not running so that the hydraulic system is not operating.

PARKING BRAKES

Lift trucks with a MONOTROL pedal

FORKS

SAFETY LABELS

WARNING: Safety labels are installed on the lift truck to give in- formation about operation and possible hazards. It is important that all safety labels are installed on the lift truck and can be read.

PRIMARY FUEL FILTER, DIESEL

Drain the water from the primary fuel filter.

FIGURE 16. PRIMARY FUEL FILTER

Source: Hyster