JUNGHEINRICH EJD 220 Self Propelled Stackers 50 Hours/ Weekly

The JUNGHEINRICH EJD 220 Self Propelled Stackers 50 Hours/ Weekly ensures that your High lift stacker is on prime working condition. Ensure the safety of your workers and the quality of your machines.

JUNGHEINRICH EJD 220 Self Propelled Stackers 50 Hours/ Weekly

The JUNGHEINRICH EJD 220 Self Propelled Stackers 50 Hours/ Weekly ensures that your High lift stacker is on prime working condition. Ensure the safety of your workers and the quality of your machines.

1.1.1 Maintenance contents

1.1.1.1 Standard equipment

Brakes

Test the function of the brakes

WARNING! Accident risk while braking

The truck’s braking response depends largely on the floor condition and the type of surface. The truck’s braking distance increases when the ground is wet or dirty.

The truck can brake in three different ways:

CAUTION!

In hazardous situations, swing the tiller to the brake position or press the emergency disconnect switch.

4.7.1 Braking with the service brake

Procedure

4.7.2 Braking with the coasting brake

Procedure

4.7.3 Inversion braking

Procedure

4.7.4 Parking brake

Hydraulic operations

Lubricate the load chains.

WARNING! Risk of accident from non-lubricated and incorrectly cleaned lift chains

Lift chains are safety-critical parts. Lift chains must not show signs of serious contamination. Lift chains and pivot pins must always be clean and sufficiently lubricated.

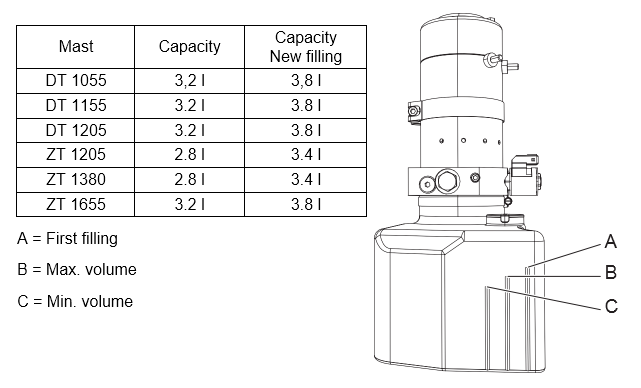

Correct the hydraulic oil level.

Requirements

Procedure

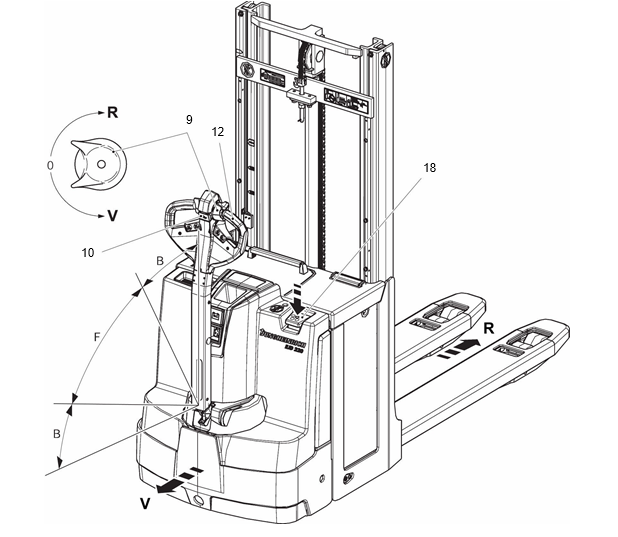

There are markings on the hydraulic reservoir. The oil level must be checked when the forks and wheel arm lift are lowered.

Steering

Procedure

The truck is steered in the required direction.

Optional equipment

Lead-acid battery, international

Power supply

Lead-acid battery

Power Supply

1.1.2 Inspection contents

1.1.2.1 Standard equipment

The following points must be checked:

Electrical system

Power supply

Travel

Chassis/structure

Hydraulic operations

1.1.2.2 Optional equipment

The following points must be checked:

Standard on-board charger

Battery charger

Lead-acid battery, international

Power supply

Lead-acid battery

Power supply

Source: Jungheinrich