JUNGHEINRICH EJD 220 Self Propelled Stackers 1000 Hours/6Months

The JUNGHEINRICH EJD 220 Self Propelled Stackers 1000 Hours/6Months ensures that your High lift stacker is on prime working condition. Ensure the safety of your workers and the quality of your machines.

JUNGHEINRICH EJD 220 Self Propelled Stackers 1000 Hours/6Months

The JUNGHEINRICH EJD 220 Self Propelled Stackers 1000 Hours/6Months ensures that your High lift stacker is on prime working condition. Ensure the safety of your workers and the quality of your machines.

1.2.1 Maintenance contents

1.2.1.1 Standard equipment

Brakes

Electrical system

Chassis/structure

Hydraulic operations

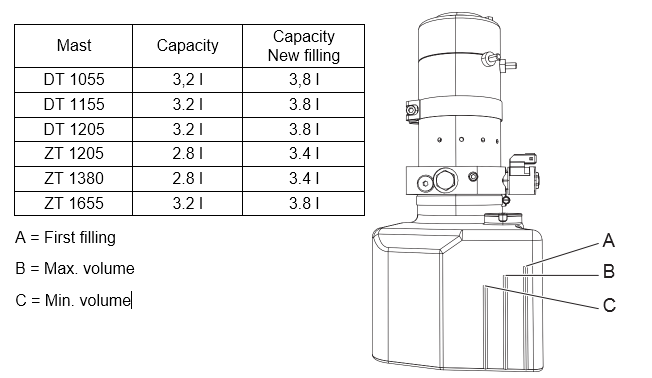

Correct the hydraulic oil level.

Requirements

Procedure

There are markings on the hydraulic reservoir. The oil level must be checked when the forks and wheel arm lift are lowered.

For the first filling approximately 0.6 litres extra must be added.

Agreed services

Steering

Procedure

The truck is steered in the required direction.

1.2.1.2 Optional equipment

Standard on-board charger

Battery charger

DANGER! Risk of electric shock and fire

Damaged and unsuitable cables can cause electric shocks and can overheat, resulting in fires.

WARNING! Risk of damage to the on-board battery charger or live attachments

Damage to the on-board battery charger or live attachments (mains cable, plug) can cause a short circuit or electric shock.

NOTICE: Improper use of the on-board charger can cause material damage

Improper use of the on-board charger can cause material damage

Data radio

System components

Lead-acid battery, international

Power supply

Clean the battery.

Lead-acid battery

Power supply

1.2.2 Inspection contents

The following points must be checked:

1.2.2.1 Standard equipment

Electrical system

Power supply

Travel

Chassis/structure

Hydraulic operations

Hydraulic operations

The function of the hydraulic system

WARNING! Leaky hydraulic systems can result in accidents

Hydraulic oil can escape from leaky and faulty hydraulic systems.

WARNING! Faulty hydraulic hoses can result in injury and infection

NOTICE:Testing and replacing hydraulic hoses

Steering

1.2.2.2 Optional equipment

Standard on-board charger

Battery charger

Electrolyte circulation

Power supply

Aquamatic

Power supply

Shock sensor / data recorder

Electrical system

Data radio

System components

Access module

Electrical system

Lead-acid battery, international

Power supply

Lead-acid battery

Power supply

1.2.3 Maintenance parts

The manufacturer recommends the replacement of the following maintenance parts at the specified intervals.

1.2.3.1 Standard equipment

1.2.3.2 Optional equipment Cold store application

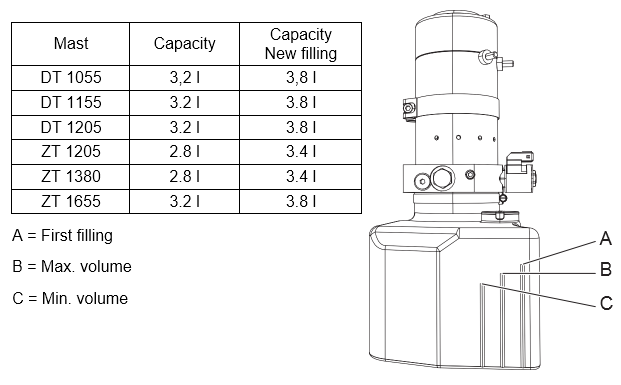

Hydraulic oil

Requirements

Procedure

There are markings on the hydraulic reservoir. The oil level must be checked when the forks and wheel arm lift are lowered.

Source: Jungheinrich