XF series 1.0-3.5t Internal Combustion Counterbalanced Forklift Truck 40-50 Hours/ Weekly

The XF series 1.0-3.5t Internal Combustion Counterbalanced Forklift Truck 40-50 Hours is a weekly maintenance form based on your daily cleaning and maintenance procedures. This form provides you a list of methods and precautionary measures to ensure great performance from your forklifts.

XF series 1.0-3.5t Internal Combustion Counterbalanced Forklift Truck 40-50 Hours/ Weekly

The XF series 1.0-3.5t Internal Combustion Counterbalanced Forklift Truck 40-50 Hours is a weekly maintenance form based on your daily cleaning and maintenance procedures. This form provides you a list of methods and precautionary measures to ensure great performance from your forklifts.

Increase the below content base on maintain daily.

Air cleaner

Please maintain the air cleaner when truck works 50-250 hours. After six times, please change air cleaner.

Note:If the working condition is bad, the cycle of maintain and change air cleaner need more frequency.

The badly work condition with dust, the cycle of maintain and change air cleaner will be short. Advice maintains one time between 8-50 hours; change it between 100-300 hours.

Maintain method:

Caution:

Please wear defend glass to avoid the dust fly up into your eyes.

It will damage the engine if not maintain and change air cleaner on time.

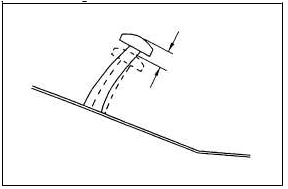

Fan belt tension check

The latest parameters please see takes engine manual parameters shall prevail.

Warning! If the belt has already been pulled long, cut out or has no surplus, it should be changed. If the engine is still running, it‘s not permitted to carry on this check avoiding fingers or sleeves being caught up in.

Power shift transmission fluid level

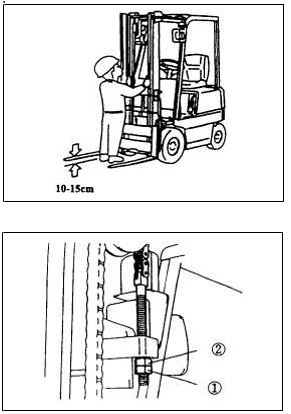

Mast and forks

Check the mast and forks to make sure:

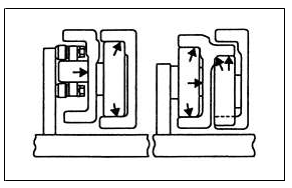

Lift chain tension check

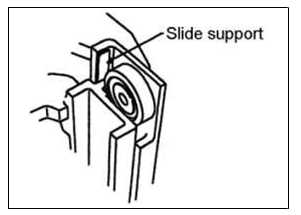

Lubrication of mast

Mast

Caution: Paint some lubrication grease; put the truck stop on a smooth road, engine flameout and tight hand brake. Prevent hand or body is clamped, and prevents falling off from high place. Keep safe.

Chain Lubrication

Lubrication grease to below parts, the detail please see <<Lubrication system drawing >>

Bolt, nut tighten

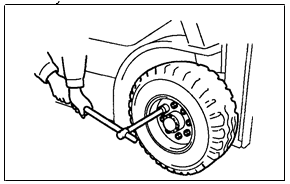

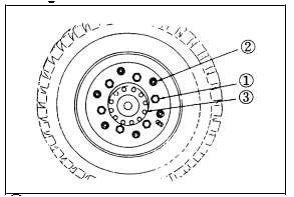

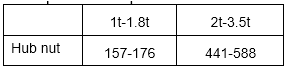

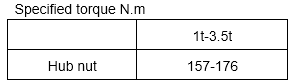

Hub nut torque check

Turning wheel(rear wheel)

Brake pedal, inching pedal and clutch pedal check

Height and the free clearance H:

Notice :QN-RW22A is the shortening of CPQD20/25/30/35N-RW22A、RW15A is shorteningCPCD20/25/30/35N-RW15A.

Source: Hangcha