4-WHEEL FRONT FORKLIFT JUNGHEINRICH EFG 318 K 1000 Hours/ 6 Months

The 4-WHEEL FRONT FORKLIFT JUNGHEINRICH EFG 318 K 1000 Hours/ 6 Months checks all parts of the forklift and ensures complete functionality. Make sure that all parts are properly maintained.

4-WHEEL FRONT FORKLIFT JUNGHEINRICH EFG 318 K 1000 Hours/ 6 Months

The 4-WHEEL FRONT FORKLIFT JUNGHEINRICH EFG 318 K 1000 Hours/ 6 Months checks all parts of the forklift and ensures complete functionality. Make sure that all parts are properly maintained.

Chassis/ superstructure

1.7 Check if labels are:

Drive unit

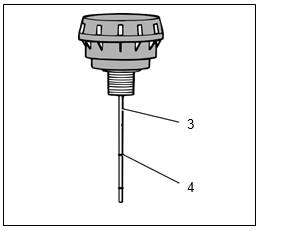

2.2 Check the transmission oil level

2.3 Check pedal mechanism and adjust and grease, if necessary

Forward motion (single-pedal)

Make sure that the driving area is free from obstacles.

Forward motion (dual-pedal)

Make sure that the driving area is free from obstacles

Changing the drive direction (single- pedal)

Before starting to drive in opposite direc- tion you have to make sure, that the rear driving area is free from obstacles

Changing the drive direction (dual-pedal)

Before starting to drive in opposite direction you have to make sure, that the rear driving area is free from obstacles.

Backward motion (single-pedal)

Make sure that the rear driving area is free from obstacles

Backward motion (dual-pedal)

Make sure that the rear driving area is free from obstacles.

Accelerating the truck (single-pedal)

Accelerating the truck (dual-pedal)

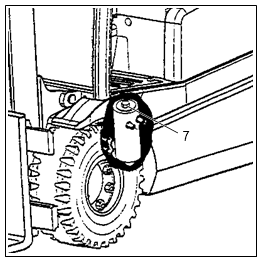

Wheels:

Steering

Brake system

5.2 Check the brake linkage;

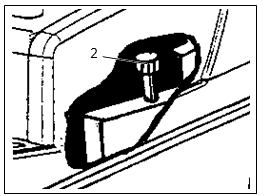

5.3 Check the brake lines, connections and brake fluid level

Brake fluid is poisonous and must only be stored in closed original containers.

Hydraulic system

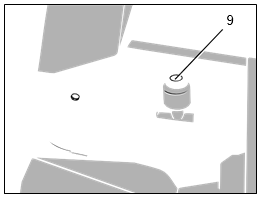

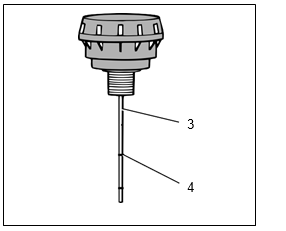

6.3 Check the oil level

The load lifting device must be completely lowered.

6.5 Check the hose line for correct functioning and damage

6.6 Change filter cartridge (hydraulic oil and deaeration filter)

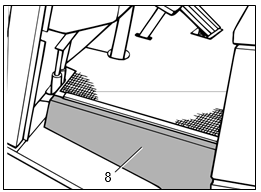

The hydraulic oil filter is located at the left side of the tilting cylinder and is accessible when the bottom plate is removed.

Electric system

Electric motors

Battery

Hoist frame

Demonstration

Source: Jungheinrich