Manitowoc Remote Ice Cube Machine Every Six Months Maintenance

The Manitowoc Remote Ice Cube Machine Every Six Months Maintenance is used to ensure your kitchen equipment continues to perform well. This is used to prevent longer harvest times and reduced capacity, which means you might not be able to keep up with the demands. In addition to diminished ice production, a number of problems can result from neglecting your ice machine's cleaning schedule and this form will help you in solving those problems.

Manitowoc Remote Ice Cube Machine Every Six Months Maintenance

The Manitowoc Remote Ice Cube Machine Every Six Months Maintenance is used to ensure your kitchen equipment continues to perform well. This is used to prevent longer harvest times and reduced capacity, which means you might not be able to keep up with the demands. In addition to diminished ice production, a number of problems can result from neglecting your ice machine's cleaning schedule and this form will help you in solving those problems.

Descaling and Sanitizing

General

You are responsible for maintaining the ice machine in accordance with the instructions in this manual. Maintenance procedures are not covered by the warranty.

Descale and sanitize the ice machine every six months for efficient operation.

If the ice machine requires more frequent descaling and sanitizing, consult a qualified service company to test the water quality and recommend appropriate water treatment.

An extremely dirty ice machine must be taken apart for descaling and sanitizing.

Manitowoc Ice Machine Cleaner/Descaler and Sanitizer are the only products approved for use in Manitowoc ice machines.

Ice Machine Inspection

Exterior Cleaning

Products containing abrasives will damage the coating and scratch the panels.

Remedial Cleaning Procedure

Detailed Descaling/Sanitizing Procedure

This procedure must be performed a minimum of once every six months.

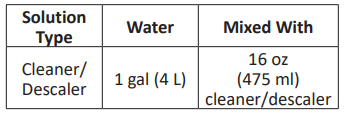

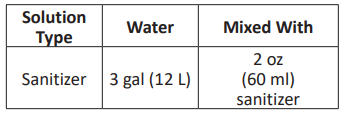

Caution: Use only Manitowoc approved Ice Machine Cleaner/De-scaler and Sanitizer for this application (Manitowoc Cleaner/De-scaler part number 9405463 and Manitowoc Sanitizer part number 9405653). It is a violation of Federal law to use these solutions in

Detailed Descaling and Sanitizing Procedure

NOTE: Although not required and dependent on your installation, removing the ice machine top cover may allow easier access.

Follow one of the methods below:

Notice: Never use anything to force ice from the evaporator. Damage may result.

Add the proper amount of ice machine cleaner/descaler to the water trough by pouring between the water curtain and evaporator, then confirm the chemical was added.

Caution: Do not mix Cleaner/Descaler and Sanitizer solutions together. It is a violation of Federal law to use these solutions in a manner inconsistent with their labeling.

Warning: Wear rubber gloves and safety goggles (and/or face shield) when handling Ice Machine Cleaner/Descaler or Sanitizer.

Warning :Disconnect the electric power to the ice machine at the electric service switch box.

Soak parts for 5 minutes (15 - 20 minutes for heavily scaled parts). Rinse all components with clean water.

Use a nylon brush or cloth to thoroughly descale the following ice machine areas:

SANITIZING PROCEDURE

When sanitizing, pay particular attention to the following areas:

Add the proper amount of ice machine sanitizer to the water trough by pouring between the water curtain and evaporator, then confirm the chemical was added.

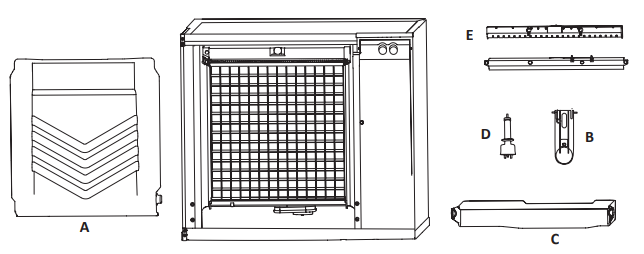

Parts Removal for Detailed Descaling and Sanitizing

A. Remove the water curtain(s)

B. Remove the ice thickness probe

If complete removal is desired, disconnect the ice thickness control wiring from the control board.

C. Remove the water trough

D. Remove the water level probe

E. Remove the water distribution tube(s)

NOTE: Thumbscrews for the distribution tube are retained to prevent loss. Loosen thumbscrews, but do not pull thumbscrews out of distribution tube.

Remedial Cleaning Procedure

NOTE: Although not required and dependent on your installation, removing the ice machine top cover may allow easier access.

Follow one of the methods below:

Notice: Never use anything to force ice from the evaporator. Damage may result.

Add the proper amount of ice machine descaler to the water trough by pouring between the water curtain and evaporator, then confirm the chemical was added.

Cleaning the Air Filter and Condenser

Warning: Disconnect electric power to the ice machine at the electric service switch before cleaning the air filter or the condenser. The condenser fins are sharp; Use care when removing or installing the air filter.

Removal from Service/Winterization

All Models

WATER-COOLED MODELS ONLY

All Models

Source: Manitowoc (www.manitowocice.com)