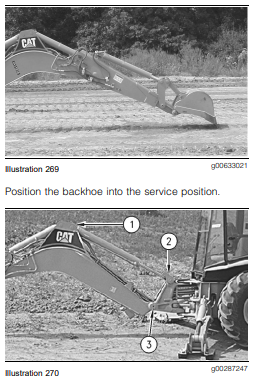

Backhoe Boom, Stick, Bucket, and Cylinder Bearings - Lubricate

Backhoe Boom, Stick, Bucket, and Cylinder Bearings - Lubricate 2

Brake Reservoir Oil Level - Check

Service Brake Holding Ability Test

Secondary Brake Holding Ability Test

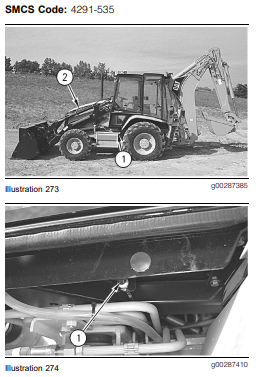

Cooling System Level - Check

Engine Air Filter Service Indicator - Inspect

Extendable Stick Pads - Inspect/Replace (If Equipped)

Fuel System Water Separator - Drain

Hydraulic System Oil Level - Check

Kingpin Bearings (Front) - Lubricate

Secondary Steering Test (If Equipped)

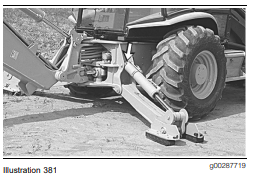

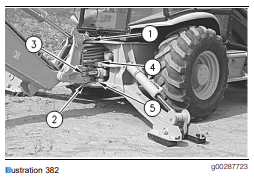

Stabilizer and Cylinder Bearings - Lubricate

Swing Frame and Cylinder Bearings - Lubricate

Transmission Oil Level - Check

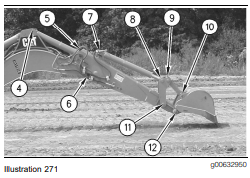

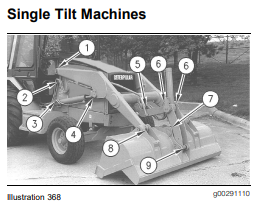

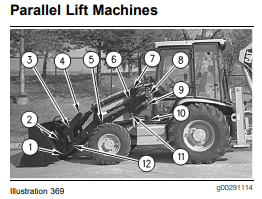

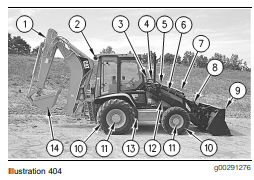

Walk-Around Inspection Inspect the backhoe bucket (14) for damage or for excessive wear. Inspect the backhoe linkage (1) for= damage or for excessive wear. Repair the bucket or the linkage, if necessary. Replace any bucket teeth, if necessary. Inspect the loader bucket (9) for damage or for excessive wear. Inspect the linkage (8) for damage or for excessive wear. Repair the bucket or the linkage, if necessary. Replace any bucket teeth, if necessary. Inspect the transmission (13) for leaks. Inspect the torque converter for leaks. Correct any leaks. Check the hoses around the transmission. Inspect the hydraulic system for leaks. Inspect the hydraulic tank (4), cylinder rod seals, hoses and tubes. Also inspect plugs, couplings and fittings. Correct any leaks. Inspect the engine compartment (6) for trash buildup. Remove any trash buildup that is in the engine compartment. Clean the screens on the engine access doors. Inspect the belts for the engine attachments (12) for worn belts, for cracked edges or for frayed edges. Replace any damaged belts. Inspect the cooling system for leaks, for faulty hoses, and for trash buildup. Correct any leaks and remove any trash buildup from the radiator (7). Inspect the tires (10) for damage and for proper inflation. Replace any missing valve caps. Tighten any loose bolts. Inspect the axles (11) for leaks. Inspect the front differential for leaks and the rear differential for leaks. Check the torque on new wheels or repaired wheels. Refer to Operation and Maintenance Manual, “Wheel Nut Torque - Check”. Inspect the engine air cleaner (5) for dirt buildup. Remove the dirt from the engine air cleaner. Service the air filter elements when the yellow piston enters the red zone on the filter service indicator. Inspect the steps and handholds (3). These objects must be clean. Also, these objects must be in good condition. Inspect the Rollover Protective Structure (ROPS) for damage. Notify your Caterpillar dealer for repairs, if necessary. Tighten any loose bolts on the ROPS. Make sure that the access covers and the guards are secured. Inspect the access covers for damage and the guards for damage. Inspect the lights (2) for broken bulbs and for broken lenses. Replace the bulbs or lenses, if necessary. Inspect the operator’s compartment for cleanliness. Keep the operator’s compartment clean. Adjust the rearview mirrors for best visibility.