2013 HYSTER H50FT Pneumatic Tire 500 Hours /3 Months

The 2013 HYSTER H50FT Pneumatic Tire 500 Hours /3 Months form provides a checklist for each part you need to inspect. Ensuring that your equipment is safe to use and gives quality performance at all times.

2013 HYSTER H50FT Pneumatic Tire 500 Hours /3 Months

The 2013 HYSTER H50FT Pneumatic Tire 500 Hours /3 Months form provides a checklist for each part you need to inspect. Ensuring that your equipment is safe to use and gives quality performance at all times.

HYDRAULIC OIL S40-70FT, S55FTS (F187)

WARNING : At operating temperature the hydraulic oil is HOT. Do not permit the hot oil to touch the skin and cause a burn.

CAUTION : Do not permit dirt to enter the hydraulic system when the oil level is checked or the filter is changed. Never operate the hydraulic pump without oil in the hydraulic system. The operation of the hydraulic pump without oil will damage the pump.

BATTERY AND CABLE TERMINALS

CAUTION: DO NOT try to start the engine by pushing or towing the lift truck. Damage to the transmission can occur if engine is started by pushing or towing lift truck.

If the battery becomes discharged and requires a booster battery to start the engine, follow these procedures carefully when connecting the jumper cables:

ENGINE OIL FILTER

DRIVE BELT

ENGINE IDLE SPEEDENGINE IDLE SPEED

ENGINE GOVERNED SPEED

ENGINE GOVERNED SPEED

FORKS

NOTE: Forks must be removed or installed by trained personnel only.

The identification of a fork describes how the fork is con- nected to the carriage. These lift trucks have hook forks.

Forks, Remove

NOTE: If lift truck is equipped with a fork positioner attach- ment, perform Step 1 first, before going to Step 2. If lift truck is not equipped with a fork positioner attachment, go to Step 2.NOTE: If lift truck is equipped with a fork positioner attach-

WARNING: Do not try to move a fork without a lifting device. Each hook fork for these lift trucks can weigh 45 to 115 kg (99 to 253 lb).

NOTE: Forks are to be replaced only in sets and not indi- vidually.

MAST

HEADER HOSES

WARNING :Lower the lift mechanism completely. Never allow any person under a raised carriage. Do not put any part of your body in or through the lift mechanism unless all parts of the mast are completely lowered and the engine is STOPPED.

Do not try to correct the alignment of the fork tips by bending the forks or adding shims. If either fork is damaged, replace the forks as a set. Never repair damaged forks by heating or welding. Forks are made of special steel using special proce- dures.

Inspect the welds on the:

Make sure that the capscrews and nuts are tight.

Visually inspect hoses/fittings for hydraulic

leaks

hose cover for cuts

cracks

defective/ broken clamping devices or sheaves

proper tracking during operation

LIFT CHAINS

Figure 33. Lift Chain Check

MAST

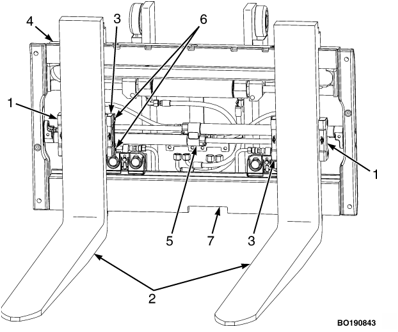

INTEGRAL SIDESHIFT CARRIAGE

MAST

MAST

BRAKE FLUID

BRAKE OIL

STEERING AXLE

Dry Brakes S40-70FT, S55FTS (F187)

Wet Brakes - Iron Case H40-70FT (L177)

Wet Brakes - Aluminum Case H40-70FT (L177)

LEFT SIDE

Right Side

Source: Hyster