Braun Dryer Efficiency & Safety Checks March/September

Regular assessments contribute to sustained operational efficiency, reducing energy consumption and minimizing downtime through the early identification of potential issues.

Braun Dryer Efficiency & Safety Checks March/September

Regular assessments contribute to sustained operational efficiency, reducing energy consumption and minimizing downtime through the early identification of potential issues.

*** LOTO Confirmation Statement - DO NOT EDIT/REMOVE ***

All hazardous energy has been isolated using LOTO procedures?

All potential stored or residual energy has been relieved, disconnected, restrained, lowered, and/or otherwise rendered safe?

Lock Out Tag Out

Food Safety Pre-Check

LOTO Performed

Clean Lint Screen

Picture Before Cleaning

Add or drag pictures

Remove Lint Basket Cover or Lint Basket and clean all areas.

Check lint basket welds and seals.

Inspect vacuum hose and ensure that there are no tears and that it is not clogged.

Picture After Cleaning

Add or drag pictures

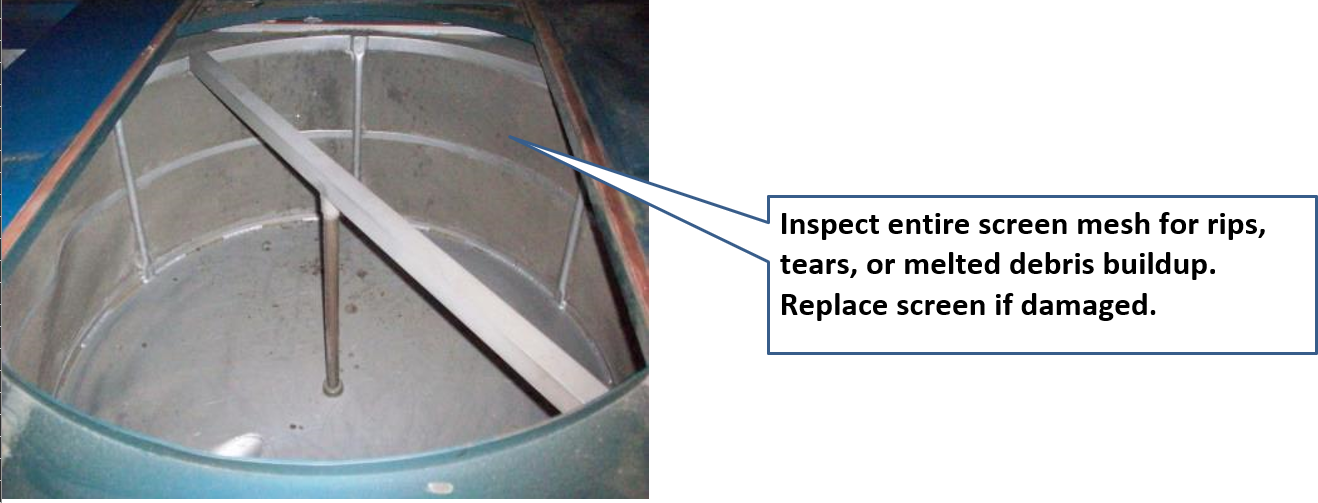

Check lint screen

Picture Before Cleaning

Add or drag pictures

Check lint screen for rips and tears. Replace lint screen if damaged.

Inspect the lint basket screen for ‘clogging’, melted nylon, or rubber build up

Pressure wash lint screen to remove all build-up.

If it can be cleaned adequately then no replacement necessary. If it cannot be cleaned adequately it must be replaced.

Check lint screen welds and seals.

Picture After Cleaning

Add or drag pictures

Check Lint Collector and Lint Collector Vacuum Screens

Picture Before Cleaning

Add or drag pictures

Inspect lint collector screen for rips and tears.

Inspect lint collector welds and seals.

Inspect vacuum hosing and ensure that there are no tears and that it is not clogged.

Pony wash internal lint vacuum bag or replace if necessary.

On heavy lint and oil operations, this task may be required to be completed more often. Ensure vacuums dampers have freedom of movement.

Picture After Cleaning

Add or drag pictures

Clean Lint from Right Side Tower

Picture Before Cleaning

Add or drag pictures

Vacuum lint from right side tower area.

Remove guards/covers and clean beneath.

Clean area of any oils/greases that may have accumulated on motors or ducting.

Picture After Cleaning

Add or drag pictures

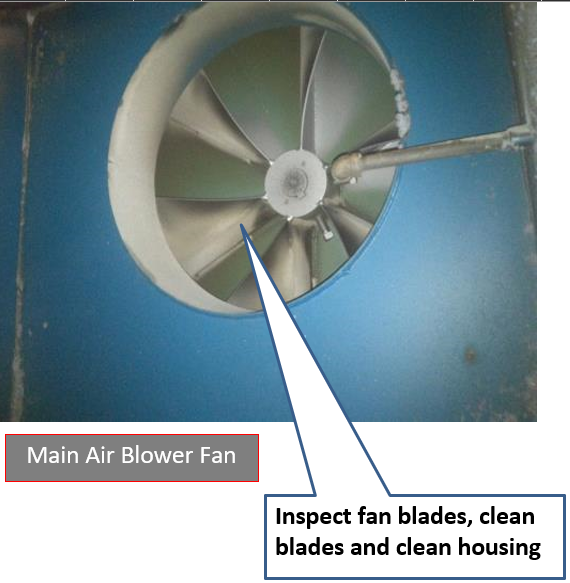

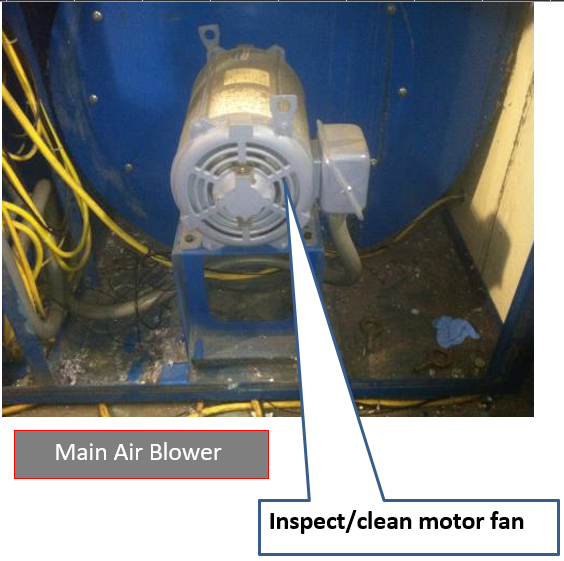

Check/Clean Main Air Blower

Picture Before Cleaning

Add or drag pictures

Remove any accumulated lint.

Inspect wheel and housing integrity.

Picture After Cleaning

Add or drag pictures

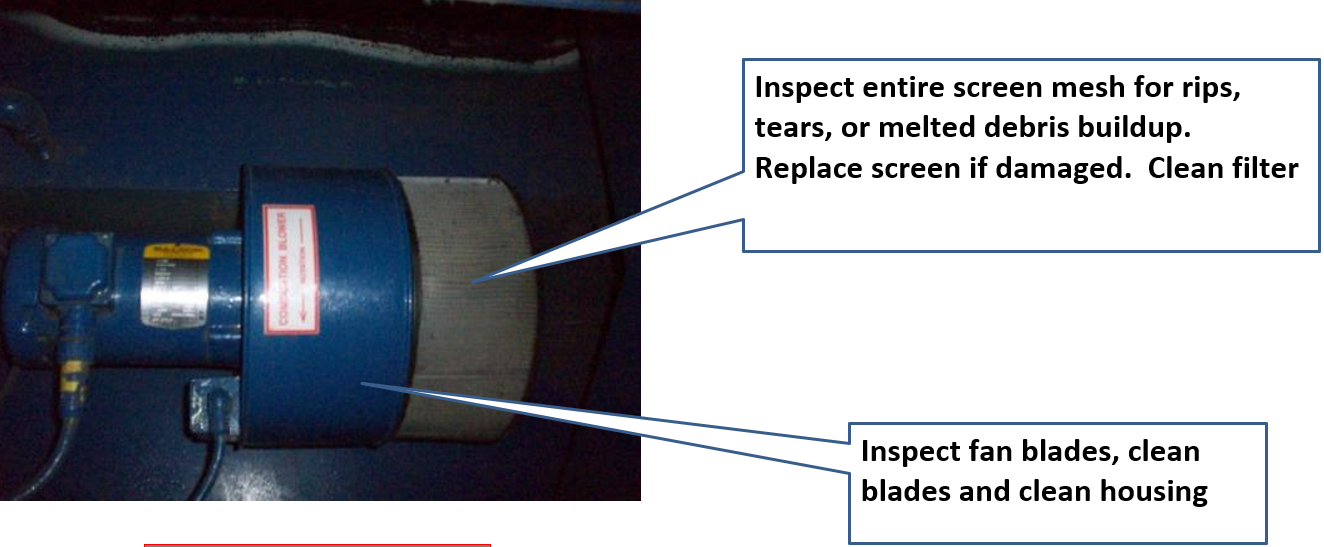

Check/Clean Combustion Blower and Filter

Picture Before Cleaning

Add or drag pictures

Remove any accumulated lint.

Inspect wheel and housing integrity.

Clean pre filter if equipped and change as necessary.

Picture After Cleaning

Add or drag pictures

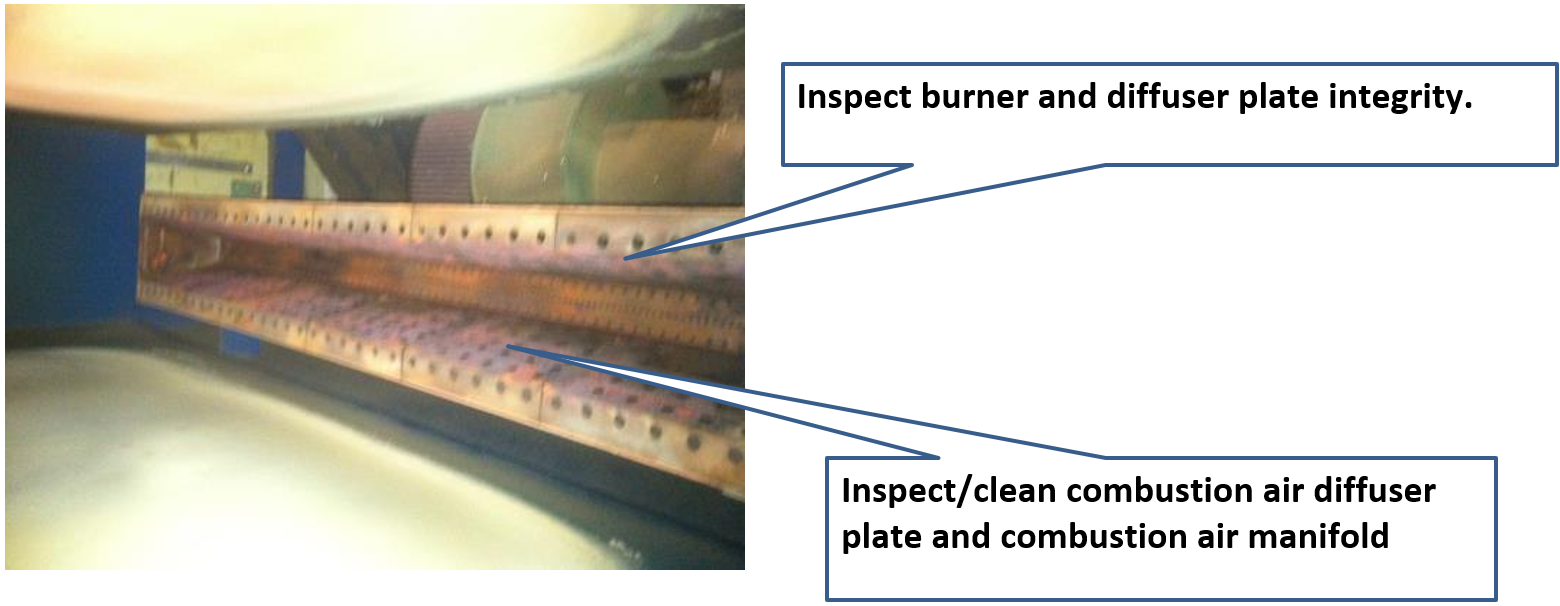

Check/Clean Burner and Combustion Air Manifold

Picture Before Cleaning

Add or drag pictures

Remove any accumulated lint from Manifold and diffuser plate.

Inspect burner and diffuser plate integrity

Picture After Cleaning

Add or drag pictures

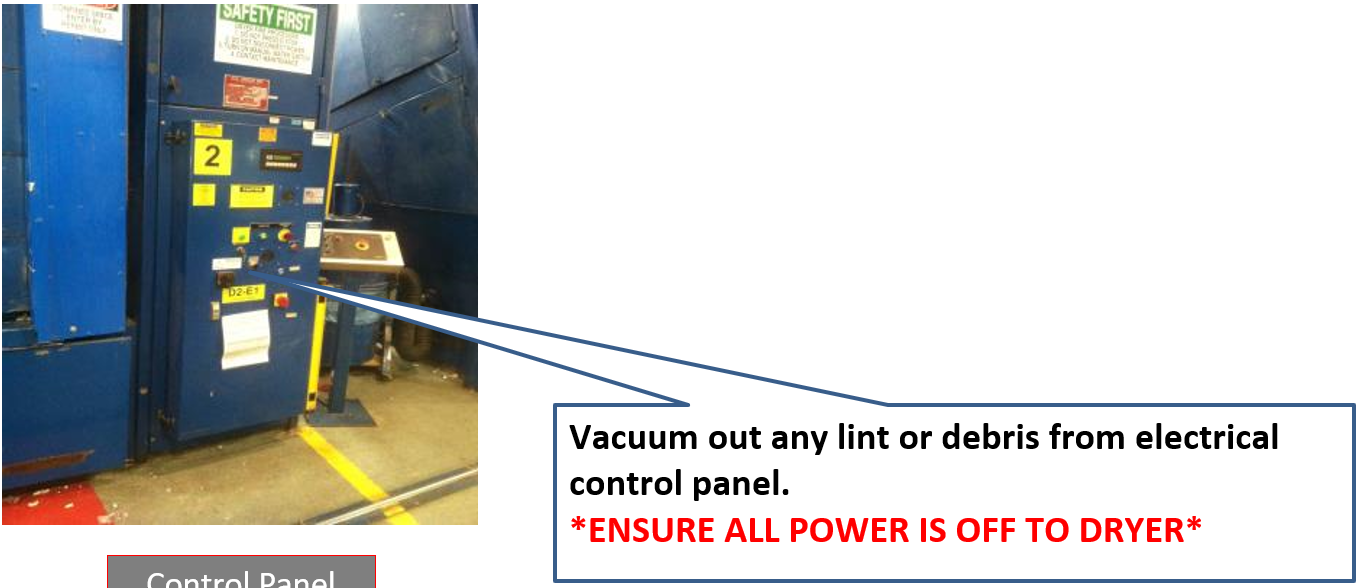

Vacuum out Control Panel

Picture Before Cleaning

Add or drag pictures

Vacuum out any lint or debris from electrical control panel.

Picture After Cleaning

Add or drag pictures

Clean Lint from Left/Right Side Dryer House

Picture Before Cleaning

Add or drag pictures

Open side panels and remove lint and debris.

Clean oil/grease from gearbox and motor.

Picture After Cleaning

Add or drag pictures

Clean Lint from Top of Dryer House

Picture Before Cleaning

Add or drag pictures

Clean lint and debris from top of dryer house.

Ensure all electrical connections and cover plates are in tact.

Remove top covers if proper cleaning was not accomplish through sides.

Picture After Cleaning

Add or drag pictures

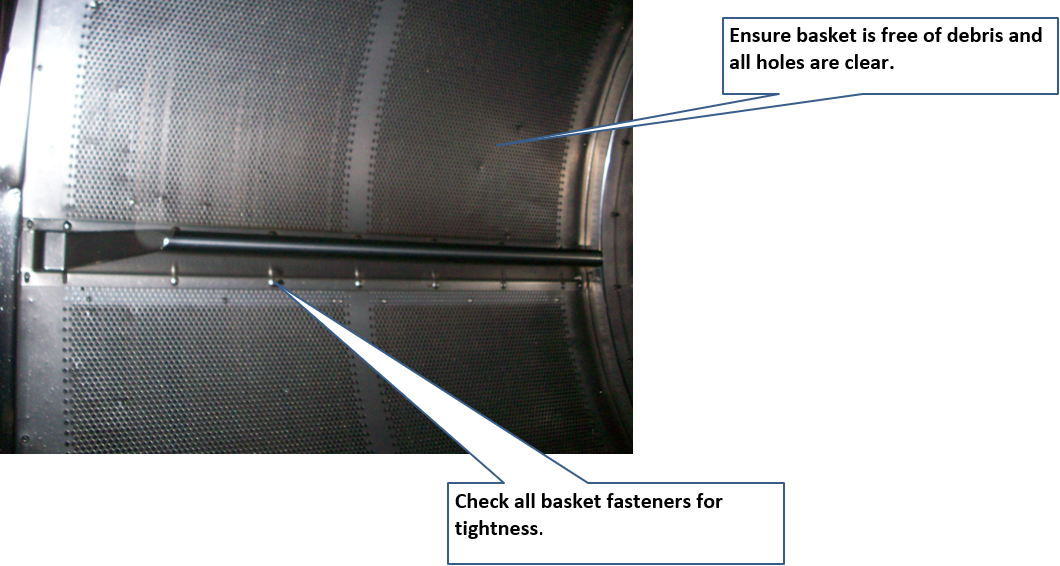

Clean Debris from Dryer Drum

Ensure basket is free of debris and all holes are clear.

Check all basket fasteners for tightness.

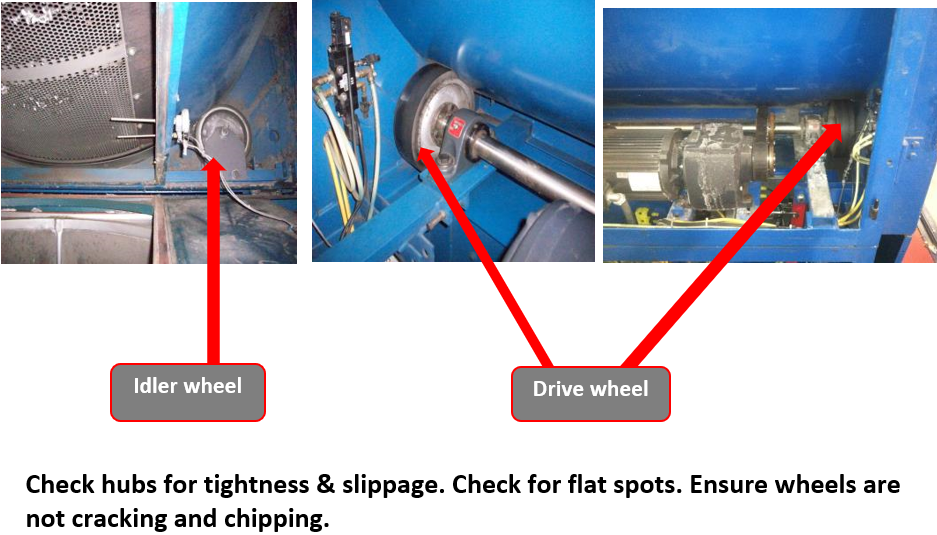

Idler and Drive wheels

Check hubs for tightness & slippage.

Check for flat spots.

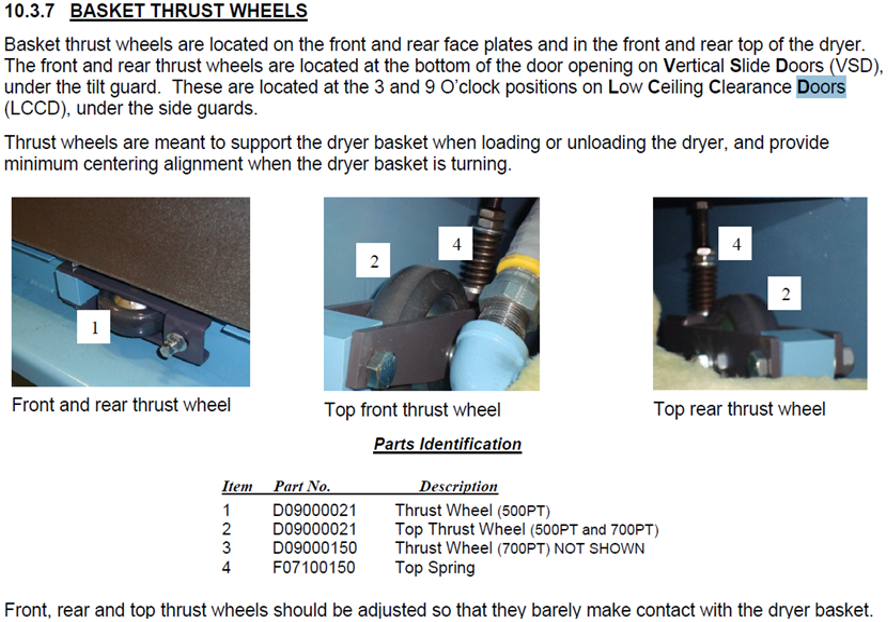

Thrust wheels

Check hubs for tightness & slippage.

Check for flat spots.

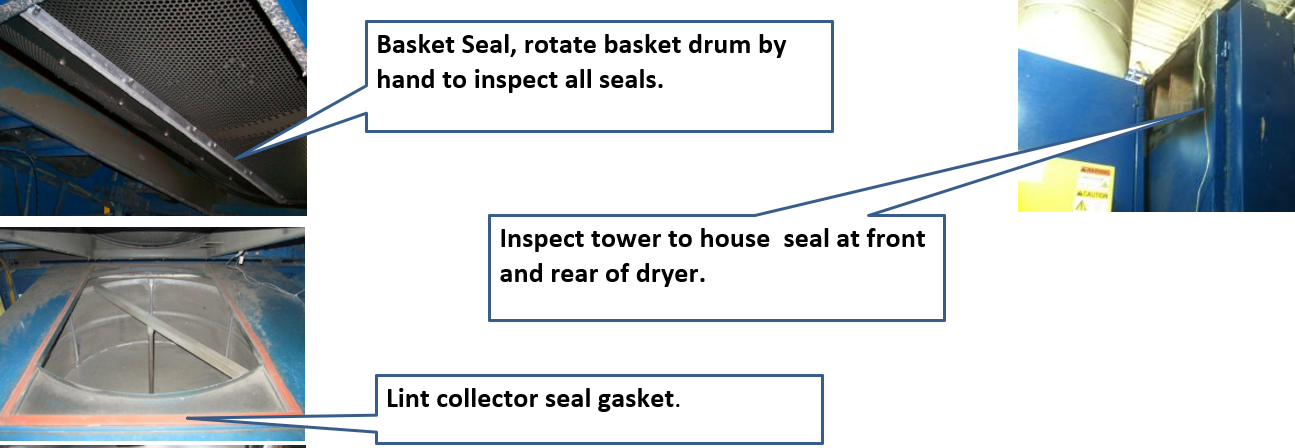

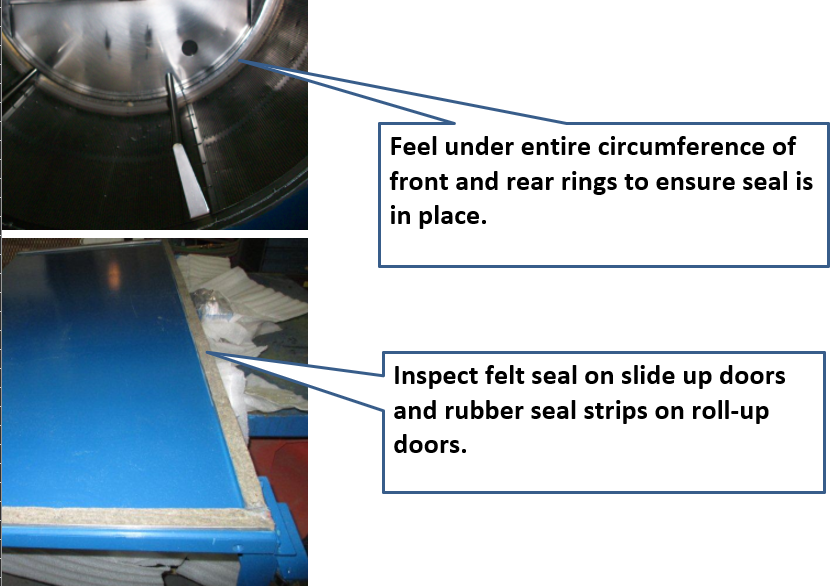

Seals

Check all seals for wear or damage, including basket wiper seals, door seals, tower seals and gap ring seals.

Drum Alignment

Drum must be aligned to prevent seal damage. Drum alignment is the process of ensuring the dryer drum and house weldment are concentric (share the same center axis).

Food Safety Post-Check

Source: 23K Justice IL - Cintas (Community Member)