Yamato Scale PM - Weekly

Yamato Scale inspection is a process that involves inspecting products at various stages during their processing to ensure quality control and assurance. This process is critical in industries like food and drink, where it’s a matter of compliance and maintaining a favorable reputation as a supplier of quality among customers.

Yamato Scale PM - Weekly

Yamato Scale inspection is a process that involves inspecting products at various stages during their processing to ensure quality control and assurance. This process is critical in industries like food and drink, where it’s a matter of compliance and maintaining a favorable reputation as a supplier of quality among customers.

Routine Checks to keep the Yamato in good working condition

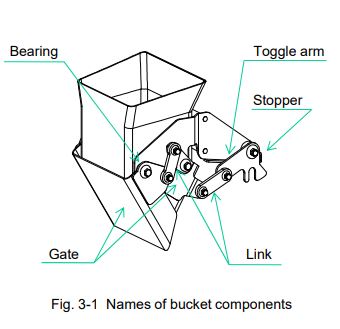

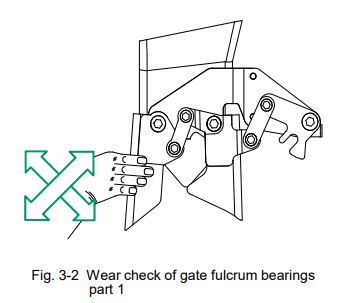

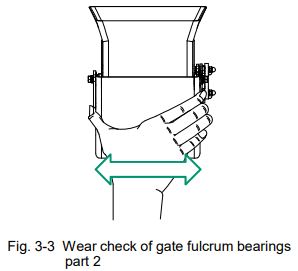

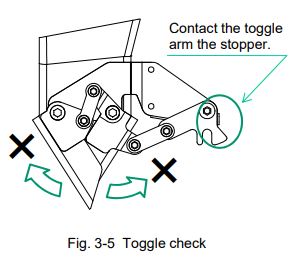

3.2 Bucket Check

The bucket bearings wear while they are used. To keep the bucket bearings in good condition at all times, be sure to check the buckets according to the following procedures.

3.3 Checking rubber parts

In the case of rubber parts used in the device such as urethane rubber and silicone rubber, check that such parts are free of defects such as wear, deformation and crack. Chip and break may result to cause infiltration of foreign matters.

Main parts where rubber parts are used

This checklist is for viewing purposes only. (Not required to check the boxes.)

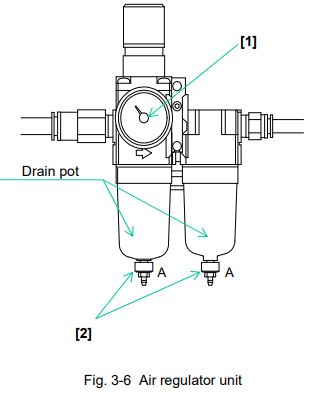

3.4 Checking the air regulator unit

In the case of the air regulator unit used, conduct check as follows.

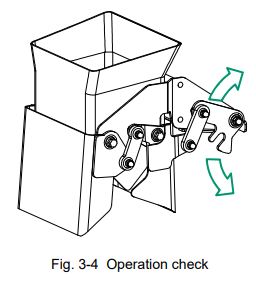

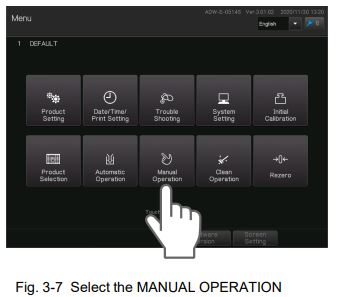

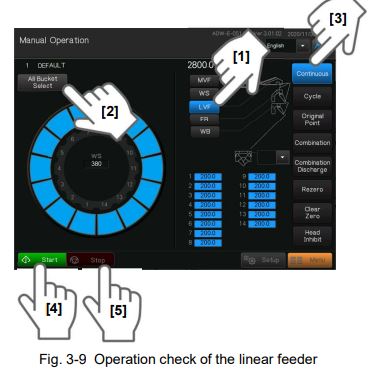

3.5 Operation check

Be sure to conduct the operation check so as to find defects such as incomplete mounting of parts and malfunctioning of the main body section to thereby ensure operation of the device in good condition at all times

(1) Main feeder

If cause of unusual operation is not fault of mounting or loosing of clamp, contact us because it is possible that defection of main feeder.

(2) Linear feeder

If cause of unusual operation is not fault of mounting or loosing of clamp, contact us because it is possible that defection of linear feeder.

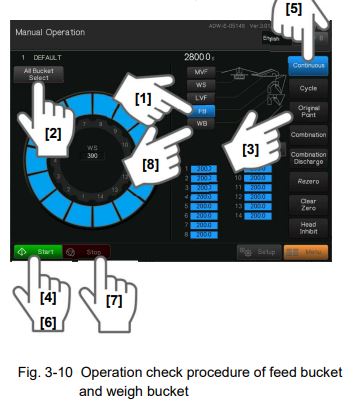

(3) Feed bucket and weigh bucket

*If the buckets should not open or close, check whether the buckets are mounted correctly. *In the case of opening/closing failure found or unusual noise heard, it is possibly because of deformation of buckets or excessively effective toggles.

(4) Memory bucket

*If the buckets should not open or close, check whether the buckets are mounted correctly. *In the case of opening/closing failure found or unusual noise heard, it is possibly because of deformation of buckets or excessively effective toggles.

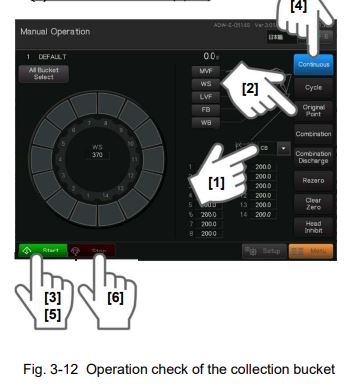

(5) Collection bucket

*If the buckets should not open or close, check whether the buckets are mounted correctly. *In the case of opening/closing failure found or unusual noise heard, it is possibly because of deformation of buckets or excessively effective toggles.

(6) Ring shutter

*In the case of malfunctioning found or unusual noise heard, check whether the skirt is in touch with parts located in the vicinity.

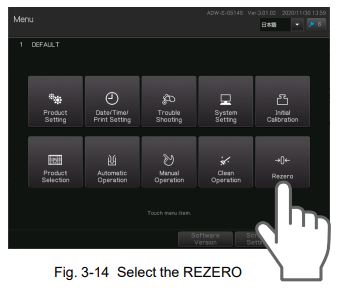

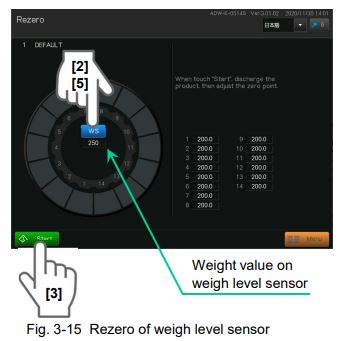

3.6 Rezero and span check

Conduct the rezero and span check of the scale before starting daily operation. Change of the zero and span of the scale would cause weighing failure.

(1) Rezero of weigh level sensor

*When the reading is not “0 g”, check whether the top cone is mounted correctly.

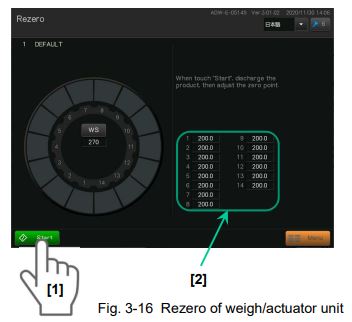

(2) Rezero of weigh/actuator unit

*The rezero is carried out after products are discharged with all buckets opened and closed. *During execution of the rezero, the display of “START” changes to “STOP”.

*if values should not be within the range specified above, check whether the weigh buckets are mounted correctly.

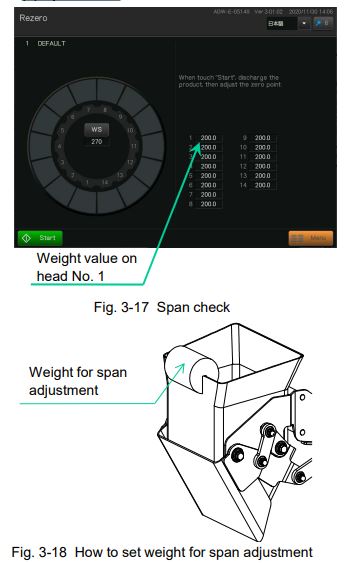

(3) Span check

*If values should not be within the range specified above, conduct the rezero.

*If the indicated weight value should be out of the range specified above and you don’t mistake weight for span , calibrate the span while referring to “4.6.2 Span calibration”.

*If the indicated weight value should be out of the range specified above, conduct the adjustment again beginning with the rezero.

Sign Here:

Click here to sign

Source: Comarco (Community Member)