Walinga Ultra- Veyors (AG) 8 Hours Maintenance

Walinga Ultra- Veyors (AG) 8 Hours Maintenance

MAINTENANCE SAFETY

Follow good shop practices:

5.1.1 FLUIDS AND LUBRICANTS

5.1.2 GREASING

Refer to Section 5.1.1 for recommended grease. Use the Service Record checklist provided to keep a record of all scheduled servicing.

5.13 SERVICING INTERVALS

Fig. 5.1 DRIVE BELTS (ALIGNMENT)

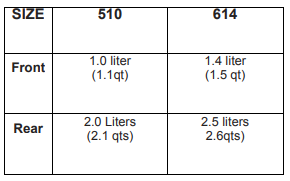

Check the oil level in the blower reservoirs (2 locations)

Front

Rear

Source: Walinga