Walinga Central Vac Systems 100 Hours or Annually Maintenance

Walinga Central Vac Systems 100 Hours or Annually Maintenance

MAINTENANCE SAFETY

Follow good shop practices:

5.1 SERVICE

5.1.1 FLUIDS AND LUBRICANTS

Grease:

Blower Oil:

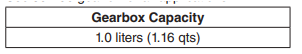

Gearbox Oil:

Storing Lubricants:

5.1.2 GREASING

Use the Maintenance Checklist provided to keep a record of all scheduled maintenance.

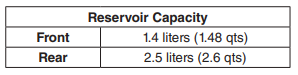

FIG. 28 BLOWER RESERVOIRS

FIG. 29 RELIEF VALVE

FIG. 30 CAMLOCKS

FIG. 31 DRAIN PLUG

Source: Walinga