Ingersoll Single Stage Electric Driven Reciprocating Air Compressor 3-5 hp (SS4L5): Quarterly or Every 500 Hours Maintenance

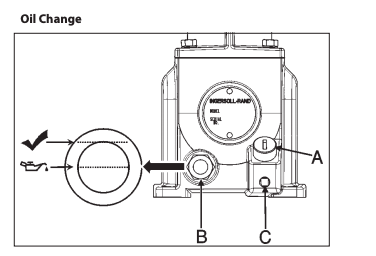

Performing the Quarterly Maintenance Tasks will help you obtain reliable and satisfactory service at all times. The procedure focuses on changing the petroleum lubricant.

Ingersoll Single Stage Electric Driven Reciprocating Air Compressor 3-5 hp (SS4L5): Quarterly or Every 500 Hours Maintenance

Performing the Quarterly Maintenance Tasks will help you obtain reliable and satisfactory service at all times. The procedure focuses on changing the petroleum lubricant.