Gas-Fired Condensing Boilers: Greenstar FS/Combi FS Inspection and Maintenance

This general maintenance procedure also serves as an inspection form. Maintenance is required for a long service life of the appliance, for effficient and economical operation, and to keep the environmental impact as low as possible.

Gas-Fired Condensing Boilers: Greenstar FS/Combi FS Inspection and Maintenance

This general maintenance procedure also serves as an inspection form. Maintenance is required for a long service life of the appliance, for effficient and economical operation, and to keep the environmental impact as low as possible.

Annual service and maintenance is required for a long service life of the appliance, for efficient and economical operation, and to keep the environmental impact as low as possible. Owners/operators are encouraged to sign a service and maintenance contract with a trained and certified installer for annual servicing and maintenance of the boiler.

DANGER: Explosion!

DANGER: Risk of flue gas poisoning.

DANGER: Risk of electric shock!

NOTICE: Insufficient antifreeze can accelerate corrosion.

Heat exchanger block inspection and cleaning

NOTICE: Damage to the coating of the heat exchanger.

Heatronic boiler control

In case of a component defect, a fault is shown on the display. The Heatronic boiler control monitors all safety and control components.

NOTICE: The Heatronic boiler control can be damaged by leaking water.

The following analytical tools are needed for service and maintenance:

After the inspection/maintenance:

Description of various steps

Calling up the latest fault (service function 6.A)

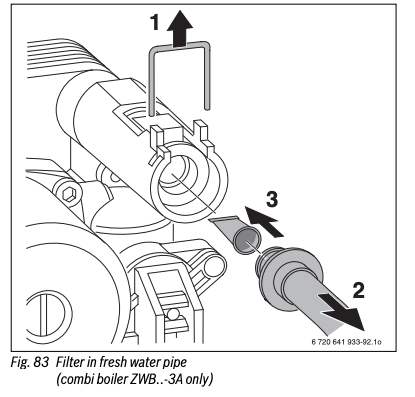

Fresh water filter (only combi boiler ZWB..-3A)

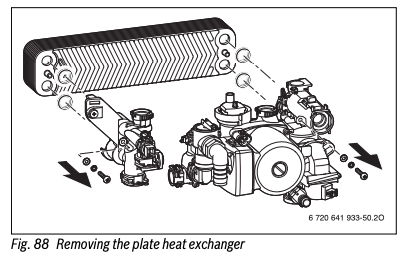

Plate type heat exchanger (only combi boiler ZWB..-3A)

If the DHW output on the combi boiler is significantly reduced:

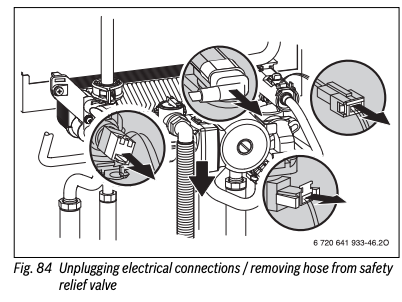

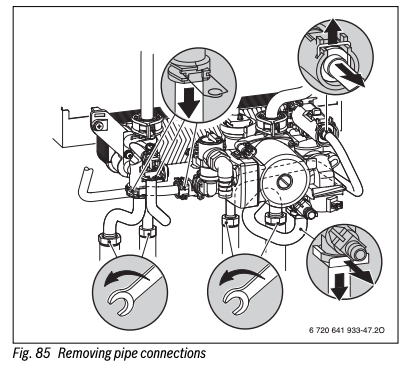

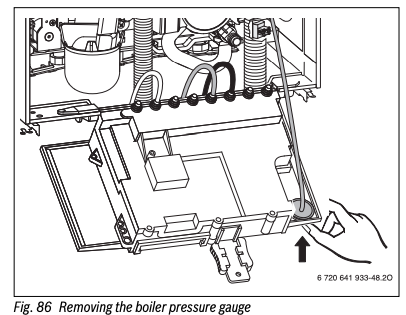

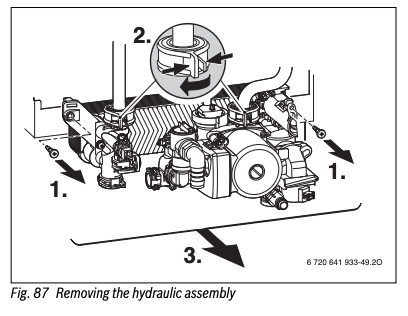

To remove the plate type heat exchanger:

▶ Remove the plate type heat exchanger.

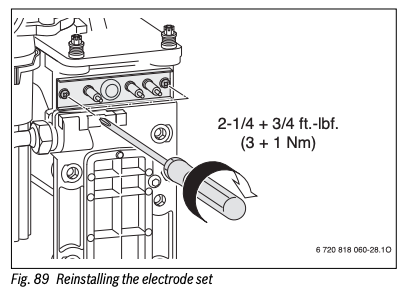

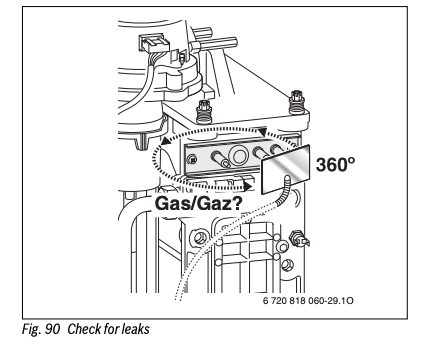

Checking the electrodes

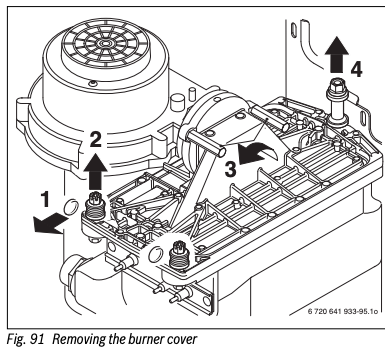

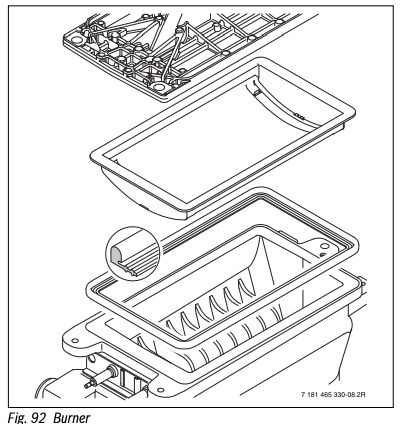

Burner servicing

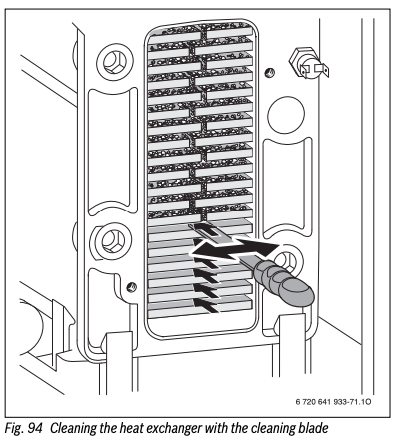

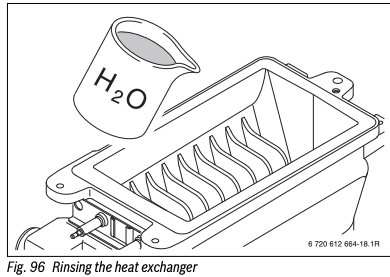

Heat exchanger block inspection and cleaning

NOTICE: Damage to the coating of the heat exchanger.

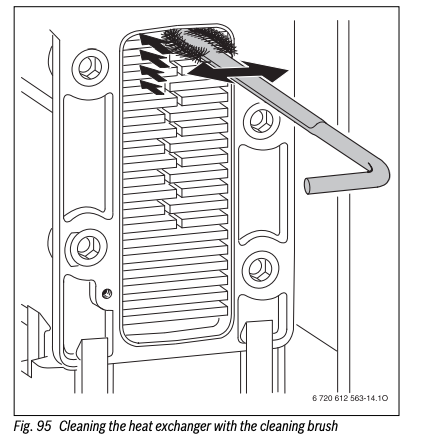

If mechanical cleaning is required:

For cleaning the heat exchanger, use Bosch main heat exchanger gaskets, the heat exchanger brush and the heat exchanger cleaning blade which are available as spare parts.

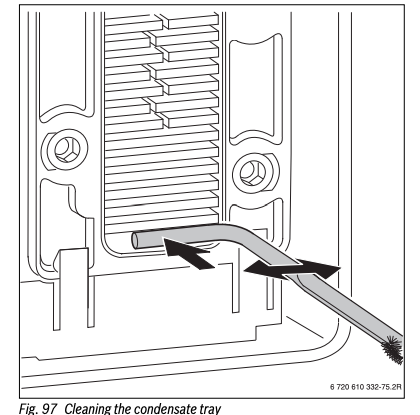

▶ Clean the condensate tray (with reversed brush).

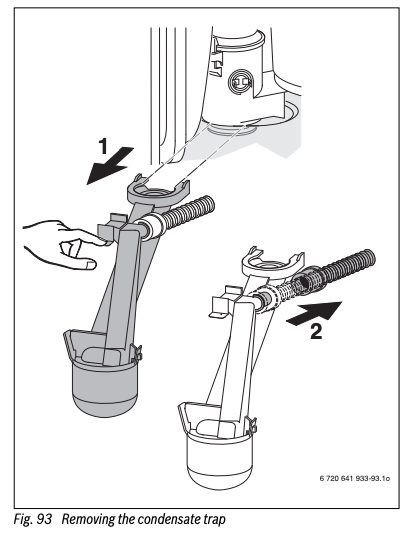

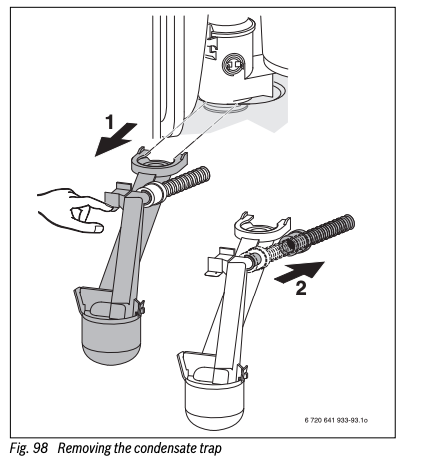

Condensate trap cleaning

▶ Remove condensate trap (steps 1 and 2) and check heat exchanger orifice for clear passage.

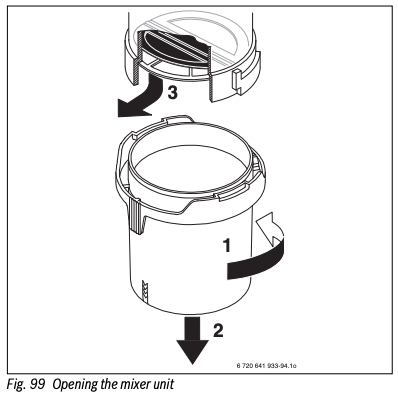

Checking the mixer diaphragm

Source: Bosch (www.bosch-climate.us)