CGAM Air-Cooled Scroll Chiller: Condenser Maintenance (6 months)

This semi-annual procedure focuses on microchannel condensers. For proper operation, microchannel condenser coils must be cleanedregularly. Performing all maintenance procedures and inspection at the recommended intervals will prolong the life of your chiller and minimize the possibility of malfunctions.

CGAM Air-Cooled Scroll Chiller: Condenser Maintenance (6 months)

This semi-annual procedure focuses on microchannel condensers. For proper operation, microchannel condenser coils must be cleanedregularly. Performing all maintenance procedures and inspection at the recommended intervals will prolong the life of your chiller and minimize the possibility of malfunctions.

Microchannel Condensers

For proper operation, microchannel condenser coils must be cleaned regularly. Eliminate pollution and other residual material help to extend the life of the coils and the unit.

Regular coil maintenance, including annual cleaning, enhances the unit’s operating efficiency by minimizing compressor head pressure and amperage draw. The condenser coil should be cleaned at minimum once each year, or more if the unit is located in a “dirty” or corrosive environment.

NOTICE: Equipment Damage!

Do not use detergents to clean coils. Use clean water only. Use of detergents on coils could cause damage to coils.

Cleaning with cleansers or detergents is strongly discouraged due to the all-aluminum construction. Water should prove sufficient. Any breach in the tubes can result in refrigerant leaks.

! WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects before servicing. Follow proper lockout/ tagout procedures to ensure the power can not be inadvertently energized. Failure to disconnect power before servicing could result in death or serious injury.

Microchannel Condenser Coil Cleaning

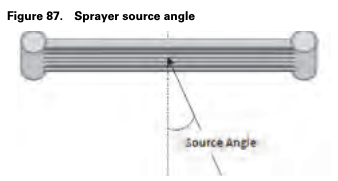

Using a sprayer and water ONLY, clean the coil following the guidelines below.

Note: To avoid damage from the spray wand contacting the coil, make sure the 90º attachment does not come in contact with the tube and fin as abrasion to the coil could result.

Important: Bridging between the main supports required before attempting to enter the unit. Bridging may consist of multiple 2 by 12 boards or sheet metal grating.

Repair/Replacement of Microchannel Coil

Microchannel coils are considerably more robust in design than tube and fin condenser coils, however they are not indestructible. When damage or a leak occurs, contact your local Trane office.

Source: Trane (www.trane.com)