Mack | Mack Transmission T318 (L)(LR)(21)(L21)(LR21) - Transmission Maintenance

Use this checklist for the regular maintenance on your Mack truck. Performing regular maintenance on your equipment has been proven to reduce repair costs for trucks and to avoid unnecessary damages.

Mack | Mack Transmission T318 (L)(LR)(21)(L21)(LR21) - Transmission Maintenance

Use this checklist for the regular maintenance on your Mack truck. Performing regular maintenance on your equipment has been proven to reduce repair costs for trucks and to avoid unnecessary damages.

Checking Oil Level

Note: Perform oil level check when the oil is at operating temperature. The vehicle must be in a level position, both front-to-rear and side-to-side.

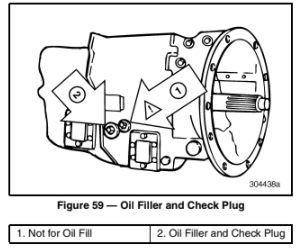

Magnetic Filter Plug (Not for Level Check)

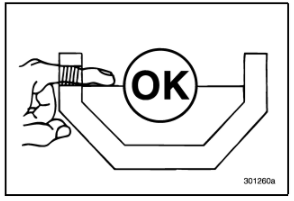

Oil Filler and Check Plug

The oil must be level with the bottom of the filler plug hole as determined by feel or by visual inspection.

Warning: Be careful not to burn your finger in hot gear oil when checking the oil level in the transmission.

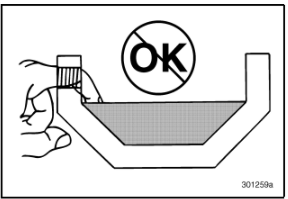

If oil can only be felt by reaching the finger down into the unit, the oil level is too low.

Incorrect Oil Level

Reinstall and tighten the oil filler plug (Figure 55) as follows:

Caution: DO NOT exceed 48 N•m (35 lb-ft) as plug can seize, resulting in damage to the transmission case when attempting to remove the plug.

Changing Oil

Caution: Preserve the environment! Drained gear oil is classified as a hazardous toxic material which must be recovered, handled, stored and disposed of according to applicable State or Federal guidelines.

CHANGE INTERVAL

Change the oil at intervals specified in the Maintenance and Lubrication Manual (TS494).

DRAINING OIL

Before draining oil from the transmission, the oil should be at normal operating temperature.

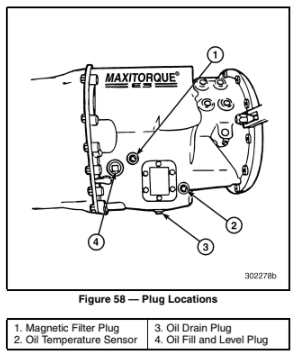

Remove the magnetic drain plug (Figure 58) from the bottom of the transmission main case and drain the hot oil into an industry-approved recovery container.

OIL FILL

Remove the oil filler plug (2) (Figure 59), then fill the transmission using specified oil until the oil is level with the bottom of the filler plug hole (also see Figure 56). Do NOT overfill.

Note: MACK-approved lubricants can be found on the internet at www.macktrucks.com, then click on the PARTS AND SERVICE category.

Reinstall and tighten the oil filler plug as follows:

Caution: DO NOT exceed 48 N•m (35 lb-ft) as plug can seize, resulting in damage to the transmission case when attempting to remove the plug.

Caution: Be sure to add oil to the transmission through the filler hole, NOT the magnetic filter plug hole. Damage to the transmission and seals may occur due to overfilling. The magnetic oil filter hole is higher on the transmission case than the filler hole.

Magnetic Oil Filter Plug

Remove the magnetic oil filter plug and clean the magnet in the plug every time the oil is changed. Reinstall the magnetic plug. Tighten the plug to 27–31 N•m (20–23 lb-ft) torque.

Air Breather(s)

The T313–T318(L)(LR)(21)(L21)(LR21) transmissions have one air breather, located on the main case shift cover.

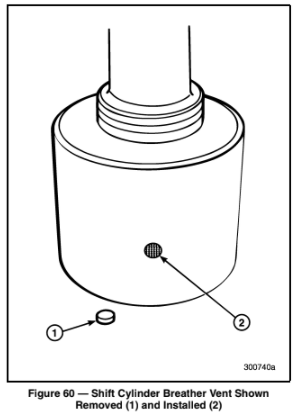

The optional three-position (compound neutralizing) range shift cylinder contains a breather vent screen which should be cleaned any time the main case shift cover is cleaned. The following figure shows the breather vent removed (1) and installed (2). Check the breather vent for free airflow. Clean or replace as necessary.

Source: MaintainX (Community Member)