Axiom™ Horizontal and Vertical Water Source Heat Pumps: DXHF 024-070 60 Hz, DXVF 024-070 60 Hz: Preventive Maintenance

This procedure is for the preventive maintenance of your unit. It has been simplified and has a list of preventive suggestions that focuses on your equipment's filter.

Axiom™ Horizontal and Vertical Water Source Heat Pumps: DXHF 024-070 60 Hz, DXVF 024-070 60 Hz: Preventive Maintenance

This procedure is for the preventive maintenance of your unit. It has been simplified and has a list of preventive suggestions that focuses on your equipment's filter.

! WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on the tags, stickers, and labels could result in death or serious injury.

Technicians, in order to protect themselves from potential electrical, mechanical, and chemical hazards, MUST follow precautions in this manual and on the tags, stickers, and labels, as well as the following instructions: Unless specified otherwise, disconnect all electrical power including remote disconnect and discharge all energy storing devices such as capacitors before servicing.

Follow proper lockout/tagout procedures to ensure the power can not be inadvertently energized. When necessary to work with live electrical components, have a qualified licensed electrician or other individual who has been trained in handling live electrical components perform these tasks.

Preventive Maintenance

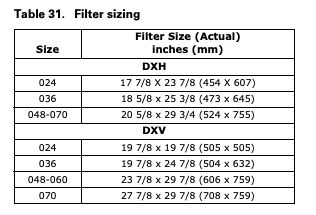

Maintenance on the unit is simplified with the following preventive suggestions:

Check the contactors and relays within the control panel at least once a year. It is good practice to check the tightness of the various wiring connections within the control panel.

A strainer (60 mesh or greater) must be used on an open loop system to keep debris from entering the unit heat exchanger and to ensure a clean system.

For units on well water, it is important to check the cleanliness of the water-to-refrigerant heat exchanger. Should it become contaminated with dirt and scaling as a result of bad water, the heat exchanger will have to be back flushed and cleaned with a chemical that will remove the scale. This service should be performed by an experienced service person.

! WARNING

Hazardous Chemicals!

Failure to follow all safety instructions below could result in death or serious injury. Coil cleaning agents can be either acidic or highly alkaline and can burn severely if contact with skin occurs. Handle chemical carefully and avoid contact with skin. ALWAYS wear Personal Protective Equipment (PPE) including goggles or face shield, chemical resistant gloves, boots, apron or suit as required. For personal safety refer to the cleaning agent manufacturer’s Materials Safety Data Sheet and follow all recomme

It should be noted that the water quality should be checked periodically (See the table below).

Condensate Trap

For units incorporating a negative trap design, ensure that the condensate system is primed with water at all times. Allowing a negative, pressure condensate system to run dry could cause a break in the condensate seal allowing the fan to draw water from the condensate line to spray moisture into the mechanical system. By maintaining a primed condensate trap, a seal will be created and will help prevent these complications.

Source: Trane (www.trane.com)