Ascend™ Air-Cooled Chiller ACR: Annual Maintenance

This procedure is the recommended annual maintenance of your equipment. You need to contact a qualified service provider to leak test the chiller, check operating and safety controls, and to inspect electrical components for proper operation. Leak testing my be accomplished using soap solution or with electronic or ultrasonic leak detectors.

Ascend™ Air-Cooled Chiller ACR: Annual Maintenance

This procedure is the recommended annual maintenance of your equipment. You need to contact a qualified service provider to leak test the chiller, check operating and safety controls, and to inspect electrical components for proper operation. Leak testing my be accomplished using soap solution or with electronic or ultrasonic leak detectors.

Maintenance

! WARNING

Hazardous Voltage - Pressurized Flammable Fluid!

Failure to follow all electrical safety precautions could result in death or serious injury. Do not operate compressor without terminal box cover in place.

The motors in the compressors have strong permanent magnet motors and have the capability to generate voltage during situations when the refrigerant charge is being migrated. This potential will be present at the motor terminals and at the output of the variable speed drives in the power panel.

Before removing compressor terminal box cover for servicing, or servicing power side of control panel, CLOSE COMPRESSOR DISCHARGE SERVICE VALVE and disconnect all electric power including remote disconnects. Discharge all motor start/run capacitors. Follow lockout/tagout procedures to ensure the power cannot be inadvertently energized. Verify with an appropriate voltmeter that all capacitors have discharged.

The compressor contains hot, pressurized refrigerant. Motor terminals act as a seal against this refrigerant. Care should be taken when servicing NOT to damage or loosen motor terminals.

! WARNING

Pressurized Burning Fluid!

Failure to follow the instructions below could result in death or serious injury. Do not operate compressor without terminal box cover in place.

The compressor contains hot, pressurized refrigerant. Motor terminals act as a seal against this refrigerant. Care should be taken when servicing NOT to damage or loosen motor terminals.

! WARNING

Hazardous Voltage w/Capacitors!

Failure to follow these instructions could result in death or serious injury.

Disconnect all electric power, including remote disconnects and discharge all motor start/run and AFD (Adaptive Frequency™ Drive) capacitors before servicing. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized.

For variable frequency drives or other energy storing components provided by Trane or others, refer to the appropriate manufacturer’s literature for allowable waiting periods for discharge of capacitors. Verify with an appropriate voltmeter that all capacitors have discharged.

DC bus capacitors retain hazardous voltages after input power has been disconnected. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized. After disconnecting input power, wait five (5) minutes for the DC capacitors to discharge, then check the voltage with a voltmeter. Make sure DC bus capacitors are discharged (0 VDC) before touching any internal components.

This section describes the basic chiller preventive maintenance procedures, and recommends the intervals at which these procedures should be performed. Use of a periodic maintenance program is important to ensure the best possible performance and efficiency.

Use an Operator Log (see Log and Check Sheet chapter) to record an operating history for unit. The log serves as a valuable diagnostic tool for service personnel. By observing trends in operating conditions, an operator can anticipate and prevent problem situations before they occur. If unit does not operate properly during inspections, see Diagnostics chapter.

Recommended Maintenance

Annual

Annual Procedures:

NOTICE:

Coil Damage! Use of detergents could cause damage to coils. Do not use detergents to clean coils. Use clean water only.

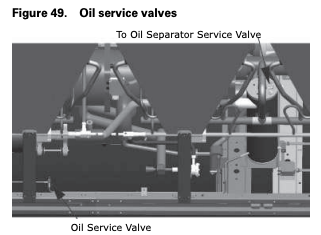

Refrigerant and Oil Charge Management

Proper oil and refrigerant charge is essential for proper unit operation, unit performance, and environmental protection. Only trained and licensed service personnel should service the chiller.

The following table lists baseline measurements for chillers running at AHRI standard operating conditions. If chiller measurements vary significantly from values listed below, problems may exist with refrigerant and oil charge levels. Contact your local Trane office.

Note: Low temperature applications units will have values that vary from the following table. Contact your local Trane office for more information.

Table 33. Typical baselines (AHRI conditions)

Lubrication System

The lubrication system has been designed to keep most of the oil lines filled with oil as long as there is a proper oil level in the oil sump.

The oil level in the sump can be measured to give an indication of the system oil charge.

Follow the procedures below to measure the level.

Important: If level is less than 4 inches from the bottom of the oil separator, contact your local Trane office

Figure 50. Nominal oil level

Drive Cooling System

NOTICE:

Equipment Damage!

Use of unapproved fluids, or dilution of approved fluid could result in catastrophic equipment damage. Use only Trane Heat Transfer Fluid P/N CHM01023. This fluid is a direct use concentration and is not to be diluted. Do not top off with water or any other fluid.

NOTICE:

Equipment Damage!

Failure to follow instructions could result in equipment damage. Drive cooling fluid and strainer must be serviced every five (5) years.

Service Intervals:

Unit Diagnostics

An improperly filled drive cooling system (either low fluid level or entrapped air in the circuit) can result in the AFD drive overheating.

This condition may result in the following diagnostic(s):

AFD xA Over Temperature:

pH Test

Obtain a sample of fluid from the drive cooling loop via the loop drain located near the oil return heat exchanger.

Test for pH level using litmus paper with a 0.5 resolution.

Pressure Relief Cap

The pressure relief cap is an automotive style pressurevent radiator cap. See figure below. The setting for the relief spring is 16 lbs. The function of the relief cap can be verified with a standard automotive radiator cap tester.

Figure 51. Pressure relief cap

Drive Cooling Expansion Tank

Proper fluid level is important to the operation of the unit. To verify proper level, inspect the liquid level in each of the fluid reservoirs (located behind the chiller control panel). See figure below for fluid levels under various temperature conditions. If levels levels are low, contact your local Trane office.

Figure 52. Drive cooling expansion tank fill

Condenser Coil Corrosion

Protection Inspection

Perform coil inspection each time coils are cleaned.

Inspect corrosion protection at each coil refrigerant connection where the copper tube joins the aluminum manifold. If damaged or missing, wrap new Prestite Insulated tar tape (STR01506) on joint to cover area from the aluminum header body to at least 2 inches of the copper tube. Seal insulation using hand pressure. Rubber gloves are suggested when handling insulation.

Note: Prestite insulated tar tape is required for all units at each copper/aluminum connection. This requirement is NOT associated with the coated coil option.

Condenser Coil Cleaning

Coil Cleaning Interval

Clean condenser coils at least once a year or more frequently if it is in a "dirty" environment. A clean condenser coil will help maintain chiller operating efficiency.

Cleaning Air Side of Coils

NOTICE:

Coil Damage!

Use of coil cleaning agents on uncoated coils could cause damage to coils. Do not use coil cleaning agents to uncoated clean coils. Use clean water only.

Do not use detergents to clean the air side of coils. Use clean water only. Clean from inside out by removing end panels.

Cleaning Microchannel Coils

For proper operation, microchannel condenser coils must be cleaned regularly. Eliminate pollution and other residual material help to extend the life of the coils and the

Regular coil maintenance, including annual cleaning, enhances the unit’s operating efficiency by minimizing compressor head pressure and amperage draw. The condenser coil should be cleaned at minimum once each year, or more if the unit is located in a “dirty” or corrosive environment.

NOTICE:

Coil Damage!

Use of detergents could cause damage to coils. Do not use detergents to clean coils. Use clean water only.

Cleaning with cleansers or detergents is strongly discouraged due to the all-aluminum construction. Water should prove sufficient. Any breach in the tubes can result in refrigerant leaks.

! WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors before servicing could result in death or serious injury.

Disconnect all electric power, including remote disconnects and discharge all motor start/run capacitors before servicing. Follow proper lockout/tagout procedures to ensure the power cannot be inadvertently energized. For variable frequency drives or other energy storing components provided by Trane or others, refer to the appropriate manufacturer’s literature for allowable waiting periods for discharge of capacitors. Verify with a CAT III or IV voltmeter rated per NFPA 70E that all capacitors have discharg

Cleaning Microchannel Coils:

Disconnect power to the unit.

Note: When possible, clean the coil from the opposite direction of normal air flow (inside of unit out) to push debris out.

Using a sprayer and water ONLY, clean the coil following the guidelines below.

Note: To avoid damage from the spray wand contacting the coil, make sure the 90º attachment does not come in contact with the tube and fin as abrasion to the coil could result.

Cleaning the Evaporator

Because the evaporator is typically part of a closed circuit, it does not accumulate appreciable amounts of scale or sludge with properly treated working fluids. However, if cleaning is deemed necessary, chemical and mechanical means are both acceptable. If using chemical means, any and all materials used in the external circulation system, the quantity of the solution, the duration of the cleaning period, and any required safety precautions should be approved by the company furnishing materials or performi

In particular, evaporators in units larger than 300 nominal tons may be equipped with a highly enhanced "micro" structure that will not behave like a typical helical structure when cleaned mechanically. This may require specialized equipment or methods to force tube cleaning heads through the tubes. In these instances, determination of brush/head type and size is critical, as using an oversized brush/head may damage the tube enhancement, while using a brush/head that is too small could result in incomplete

Free-Cooling Coil

Free-Cooling Coil Cleaning

Regular coil maintenance enhances the unit's operating efficiency by optimizing free-cooling heat transfer and amperage draw. The free cooling coil should be cleaned at minimum once each year, or more if the unit is located in a dirty or corrosive environment.

Free-cooling coil cleaning process is the same as condenser coil cleaning.

Free-Cooling Fluid Management

NOTICE:

Equipment Damage!

Failure to follow instructions below could result in equipment damage.

DO NOT USE UNTREATED WATER. Glycol solution must be utilized with the Direct Free Cooling option. Glycol percentage should be based on freeze avoidance requirements. The glycol solution requires an inhibitor package to be carefully chosen with the aid of qualified water treatment specialist to abate corrosion in a mixed metal system.

The building glycol loop should not be vented to atmosphere. A closed system is required to limit oxidation potential within the loop. Make-up water should be avoided.

NOTICE:

Coil Damage!

Failure to follow instructions below could result in free-cooling coil freeze. For units with free-cooling option, introduction of uninhibited water into the system is not recommended, as it could lead to internal corrosion and risk of coil freeze.

To avoid freecooling coil damage:

The direct free cooling option circuit consists of copper, carbon steel, cast iron, zinc, EPDM rubber, brass, and Aluminum AA3102, AA3003, AA4045 in addition to other materials that may be in the building loop connected to the chiller. The inhibited glycol solution should be selected at desired concentration to insure adequate inhibitor content. It is not advised to dilute a stronger concentrate due to inhibitor dilution. Glycol fluid should be free from foreign solid particles. A maintenance schedule shoul

Reinstallation of Compressor Mounting Bolts

Units with InvisiSound™ Ultimate Only (Model Number Digit 13 = E)

If compressor removal or unit move is required on a unit with InvisiSound™ Ultimate option, reinstall compressor mounting bolts which were removed per installation or maintenance instructions.

Servicing Chiller Roof

! WARNING

Do Not Climb on Top of Unit!

Failure to follow these instructions could result in technician falling off the equipment which could result in death or serious injury. Do not climb on roof to service unit. Use service tools designed to access top of chiller.

Source: Trane (www.trane.com)