Omnizone™ Constant Volume Water-Cooled Heat Pump Maintenance

The simple routine maintenance as described in this procedure will enhance your air conditioning system’s ability to operate economically and dependably. It has detailed instructons on how to clean the unit exterior, coil cleaning and condensate drains.

Omnizone™ Constant Volume Water-Cooled Heat Pump Maintenance

The simple routine maintenance as described in this procedure will enhance your air conditioning system’s ability to operate economically and dependably. It has detailed instructons on how to clean the unit exterior, coil cleaning and condensate drains.

Date:

Hot water, steam, and direct expansion coils must be cleaned at least once a year to maintain peak performance. Dirty coils can contribute to decreased heating or cooling capacity and efficiency, increased operating costs, and compressor problems on direct expansion systems.

Cleaning Unit Exterior

Coil Cleaning

Condensate Drains

! CAUTION

Follow all safety codes. Wear safety glasses and rubber gloves when using inhibited hydrochloric acid solution. Observe and follow acid manufacturer’s instructions.

Water-Cooled Condensers

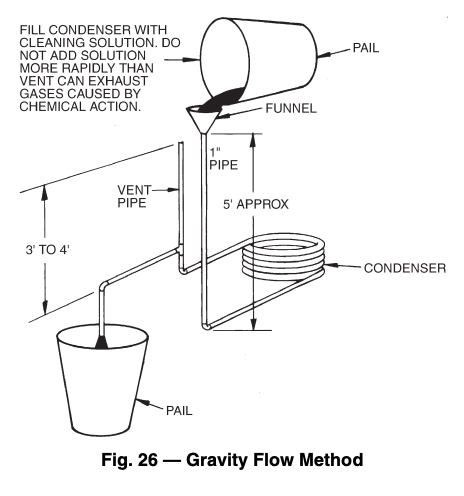

GRAVITY FLOW METHOD (FIG. 26)

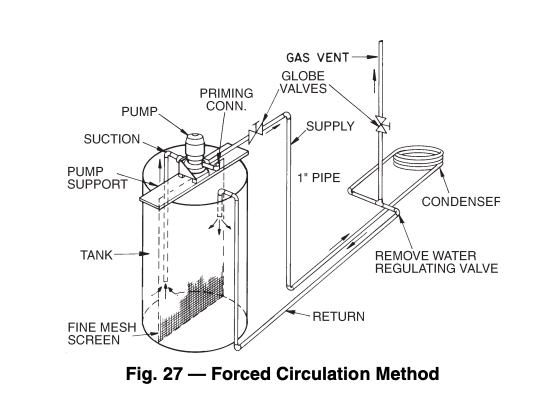

FORCED CIRCULATION METHOD (FIG. 27)

Fan Motor Lubrication

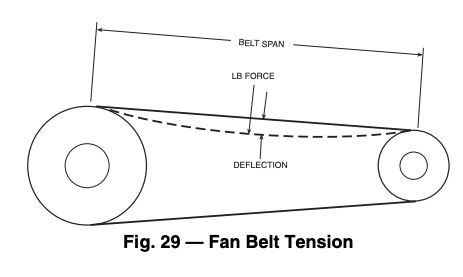

Factory-supplied drives are pre-aligned and tensioned; however, it is recommended that the belt tension and alignment be checked before starting the unit. Always check the drive alignment after adjusting belt tension.

Fan Sheaves

To install sheaves on the fan or motor shaft:

Each factory-assembled fan, shaft, and drive sheave assembly is precision aligned and balanced. If excessive unit vibration occurs after field replacement of sheaves, the unit should be rebalanced. To change the drive ratio, follow the steps in the Evaporator Fan Performance Adjustment section (page 55).

page 55). After 1 to 3 minutes of operation, check the belt tension. Also check tension frequently during the first 24 hours of operation and adjust if necessary. Periodically check belt tension throughout the run-in period, which is normally the initial 72 hours of operation.

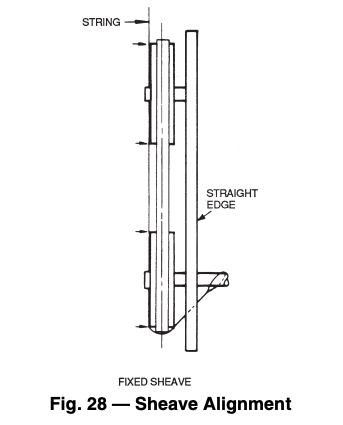

The most common causes of misalignment are nonparallel shafts and improperly located sheaves. Where shafts are not parallel, belts on one side are drawn tighter and pull more than their share of the load. As a result, these belts wear out faster, requiring the entire set to be replaced before it has given maximum service. If misalignment is in the sheave, belts enter and leave the grooves at an angle, causing excessive belt and sheave wear.

ALIGNMENT

Shaft Alignment

Sheave Alignment

Evaporator Fan Performance Adjustment

To change fan speeds from factory settings:

To align fan and motor pulleys:

BELT TENSION ADJUSTMENT

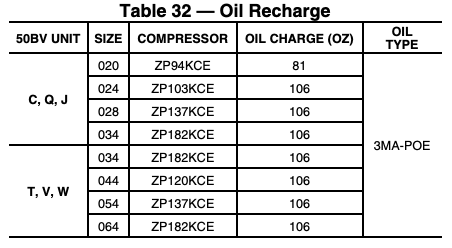

All units are factory charged with oil. It is not necessary to add oil unless compressor(s) is removed from the unit. If necessary, oil can be removed/charged via Schrader fitting.

Compressor Oil

Source: Carrier (www.shareddocs.com)